40

Electrical

System

Tractors,

Lawn

and

Garden

-

110

and

112

10-10

Ignition

System

SM-

2059-

(Apr-

67)

S

PARK

PLUG-Continued

Use

a

spark

plug

wrench

to

remove

plug.

Always

use

a

new

spark

plug

gasket

when

re-

placing

plu

g.

Examine

the

firing

end

of

the

spark

plug,

not-

ing

the

type

of

cleposits

and

the

degr

ee

of

elec-

trode

erosion.

Refer

to

pag-es

10-3

and

10-4

for

various

types

of

spark

plug

fouling

ane!

their

causes.

Clean

the

plug

on

a

sand

blast

clc<.lner,

fol-

lowing

manufacturers

instructions.

Do

not

pro-

long

the

use

of

the

abrasive

blast

as

it

will

erode

the

insulator

and

electrodes.

Clean

ALL

abrasive

from

plu<;>:

before

turning

into

engine.

Brush

threads

with

a

wire

brush.

Clean

the

electrode

surfaces

with

a

small

file,

Figure

18.

Dress

the

electrodes

to

obtain

flat

parallel

surfaces

on

both

the

center

and

siele

electrode.

After

cleaning,

examine

the

plug

carefully

for

cracked

or

broken

insulator,

badly

pitted

elec-

trodes,

and

other

signs

of

failure.

Replace

if

damaged.

Adjust

spark

plug

gap,

Fi~ure

30.

Torque

plug

to

recommenclec\

specifications.

BREAKER

POINTS

M

5600

Fig.

19-Burncd

Breaker

Poi"ts

Breaker

points

can

be

burned

from

exces-

sively

high

voltage,

oily

or

dirty

points,

a

faulty

condenser

or

improper

point

adjustment.

Pitted

points

and

some

transfer

of

material

between

the

points

is

considered

normal.

If

point

transfer

is

0.020

inch

or

more,

replacp

the

points.

Rough

contacts

which

are

g

reyish

in

cOlor

often

have

a

greatel'

area

of

cont

a

ct

than

new

con-

tacts,

and

will

provicle

satisfactory

s l'

l'vicf'

un-

til

most

of

the

tungsten

is

worn

of

1.

Clean

the

points

with

a

few

strokes

of

n

clean

oil

free

fine-cut

contact

(riffle)

file.

Do

not

attempt

to

remOV2

all

roug'hness

nor

dress

the

point

surfaces

smooth;

merely

remove

the

seale

or

dirt.

Never

use

emery

cloth

or

sand

papp.r

to

clean

the

points

since

abrasive

particles

will

embed

in

the

point

surface

and

cause

arcing

and

rapid

burning

of

the

po

ints.

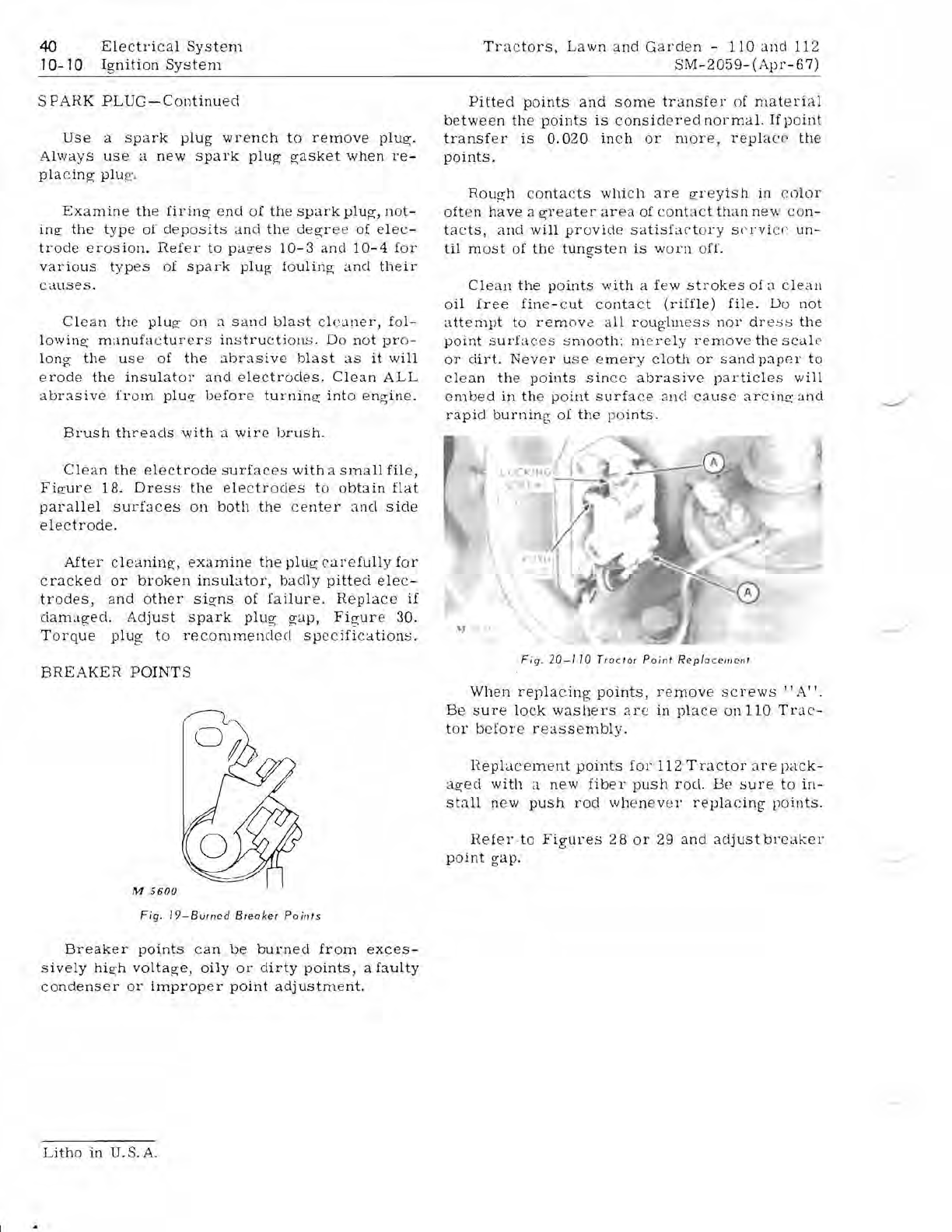

~,

Fig

,

20-110

Tractor

Point

Replacement

When

replacing

points,

remove

screws

I I A'

I.

Be

sure

lock

washers

arc

in

place

on

110

Trac-

tor

before

reassembly.

Heplacement

points

for

112

Tractor

are

pack-

agee!

with

a

new

fiber

push

rod.

Be

sure

to

in-

stall

new

push

rod

whenever

replaCing

points.

Refer·to

Figures

28

or

29

and

adjust

breaker

point

gap.

Litho

in

U.

S.

A.