40

Electrical

System

Tractors,

Lawn

and

Garden

-

110

and

112

15-2

Charging

System

SM-2059-

(Apr-67)

TESTING

Provided

here

are

instructions

for

testing

electrical

components

on

and

off

the

tractor.

The

purpose

of

the

tests

is

to

isolate

the

cause

of

the

trouble

in

the

generating

system.

A

com-

plete

diagnosis

guide

is

in

Group

5

of

this

section.

Adequate,

approved

electrical

test

equipment

is

required

to

accurately

test

electrical

circuits

and

intelligently

diagnose

unsatisfactory

per-

formance.

Many

servicemen

prefer

to

have

their

elec-

trical

components

tested

by

professionals

using

highly

complex

test

equipment.

Good

automotive

repair

centers

provide

this

service.

The

motor-

generator

and

voltage

regulator

can

be

tested

on

automotive

test

equipment.

The

following

test

procedures

are

recom-

mended

for

dealers

having

their

own

test

equip-

ment.

Equipment

needed

is

listed

at

the

end

of

this

section.

IMPORTANT

:

Because

there

are

many

man-

ufacturers

of

test

equipment,

each

with

their

own

specific

operating

instructions,

it

is

important

to

follow the

manufacturers

recommendations

if

the

procedures

in this

section

should

contradict

those

of

the

manufacturer.

TESTING

CIRCUIT

WIRING

~

P

OO

R

OR

LOOS

E

CO

N

NECT

IONS

~

COR

R

OD

EU

CO

N

NE

CT

IONS

L

WIRES

M 5 87 6

Fig.

3-Foulty

Wiring

The

wiring

in

the

circuit

is

just

as

important

a

part

of

the

charging

system

as

the

electrical

units

themselves.

Undersize

wire

or

loose

con-

nections

between

the

regula

tor

and

battery

or

poor

ground

connections

between

the

battery

and

generator

will

cause

a

lowering

of

the

charging

rate

to

the

battery.

High

resistance

resulting

from

loose

or

corroded

connections

in

the

charg-

ing

circuit

between

the

generator

and

regulator

will

result

in

a

high

voltage

at

the

generator

and

may

cause

premature

failure

of

the

regulator

pOints.

Litho

in

U.S.A.

A

visual

inspection

will

often

reveal

much

useful

information

relative

to

the

condition

of

the

charging

system.

An

wiring

should

be

vis-

ually

inspected

periodically

for

damaged

insula-

tion.

Faulty

wiring

should

be

replaced.

All

terminals

should

be

checked

for

loose

or

corrod-

ed

connections.

Terminals

should

be

cleaned

and

tightened

if

necessary.

Unwanted

resistance

in

the

circuit

results

in

unwanted

voltage

losses

or

drops.

EXCESSIVE

voltage

drop

in

the

charging

circuit

tends

to

keep

the

battery

in

an

undercharged

condition.

TESTING

MOTOR-GENERATOR

OF

F

TRACTOR

First

check

motor-generator

on

tractor

as

ex-

plained

on

page

10-7

of

Section

40.

Then,

per-

form

the

no-load

test

as

instructed

below

with

the

motor-generator

removed

from

the

tractor.

MOTOR-GENERATOR

NO

LOAD

TEST

V/\R

I

All

Ll

R[SI

S

T~NC

[

VOLT

M

E

TE

~

M 5

76

4

R .

P.

i'l .

I

IiDIC

A

TO

R

AM

ME

TEr{

.,

An

,..----"

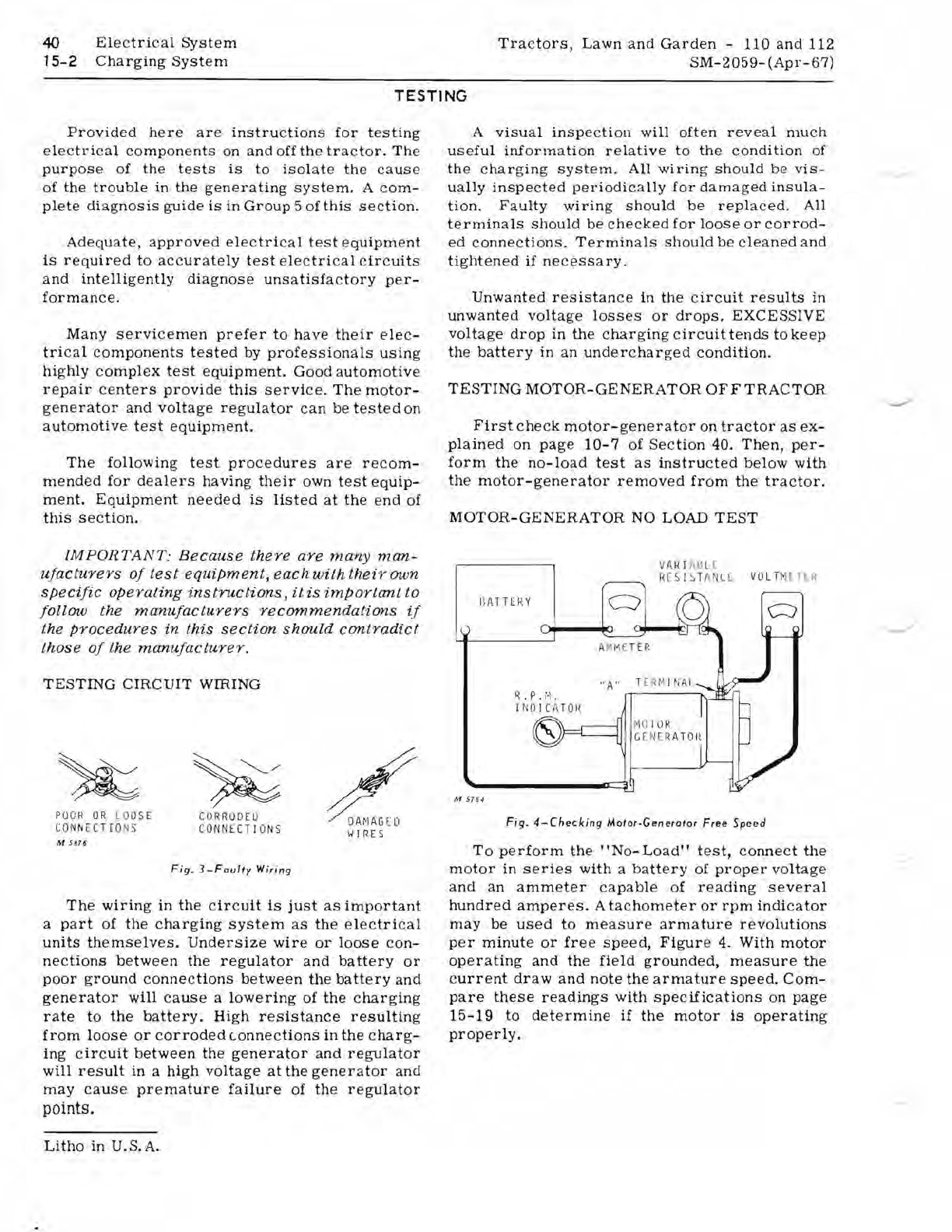

Fig.

4-Checking

Motor·Generotor

Free

Speed

To

perform

the

"No-

Load"

test,

connect

the

motor

in

series

with

a

battery

of

proper

voltage

and

an

ammeter

capable

of

reading

several

hundred

amperes.

A

tachometer

or

rpm

indicator

may

be

used

to

measure

armature

revolutions

per

minute

or

free

speed,

Figure

4.

With

motor

operating

and

the

field

grounded,

measure

the

current

draw

and

note

the

armature

speed.

Com-

pare

these

readings

with

specifications

on

page

15-19

to

determine

if

the

motor

is

operating

properly.