50

Power

Train

Tractors,

Lawn

and

Garden

-

110

and

112

20-10

4-Speed

Transaxle

SM-2059-

(Apr-67)

INSPECTION

Wash

all

internal

parts

in a

safe

cleaning

solvent.

Brush

and

scrape

foreign

matter

from

all

parts

and

dry

thoroughly.

NOTE:

Oil

the bearin.gs

irrmiediately

after

cleanin.g to

prevent

rusting.

INSPECTING

GEARS

AND

SHAFTS

Replace

all

gears

having

chipped,

broken

or

worn

teeth.

Badly

scored

gears

must

be

replaced.

Replace

any

shaft

that

is

bent,

scored

or

worn.

Replace

any

shaft

showing

side

wear

or

if

any

of

the

splines

are

damaged.

When

the

gears

slide

out

of

gear,

especially

under

load,

gear

chipping

or

cracking

will

result.

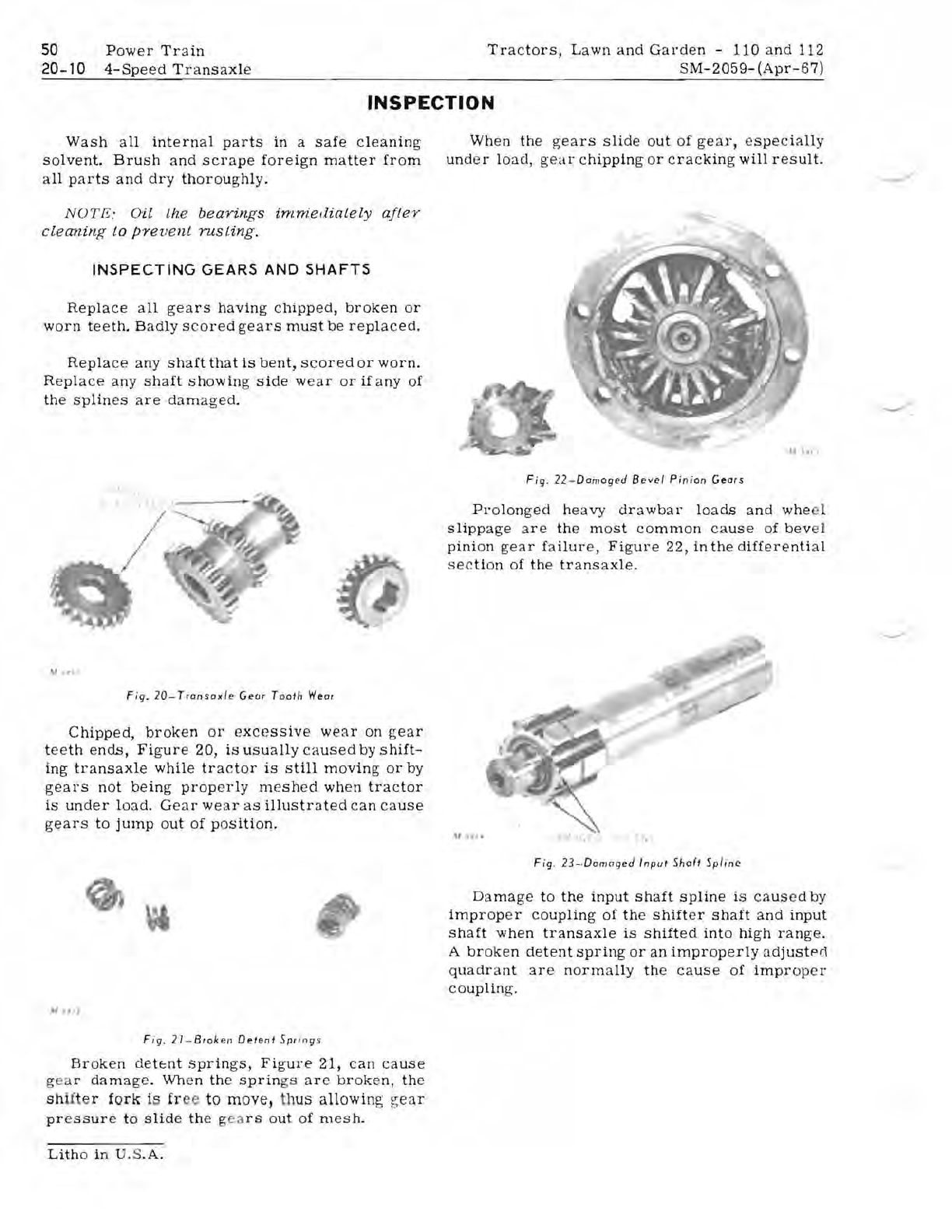

Fig.

22-Domoged

Bevel

Pinion

Gears

Pi'olonged

heavy

drawbar

loads

and

whe

el

slippage

are

the

most

common

cause

of

bev

el

pinion

gear

failure,

Figure

22,

in

the

differential

section

of

the

transaxle.

\1

,."

Fig.

20-

Tronsox/e

Gear

Tooth

Weor

Chipped,

broken

or

excessive

wear

on

gear

teeth

ends,

Figure

20,

is

usually

caused

by

shift-

ing

transaxle

while

tractor

is

still

moving

or

by

gears

not

being

properly

meshed

when

tractor

is

under

load.

Gear

wear

as

illustrated

can

cause

gears

to

jump

out

of

position.

Fig.

27-Broken

De,ent

Springs

Broken

detent

springs,

Figure

21,

can

cause

gea

r

damage.

When

the

sprin

gs

are

broken,

the

shifter fork is fr ee

to

move, thus allowing gear

pressure

to

slide

the

gea

rs

out

of

mesh.

Litho

in

U.

S

.A.

Fig.

23-Domoged

Input

Shaft

Spline

Damage

to

the

input

shaft

spline

is

caused

by

improper

coupling

of

the

shifter

shaft

and

input

shaft

when

transaxle

is

shifted

into

high

range.

A

broken

detent

spring

or

an

improperly

adjusted

quadrant

are

normally

the

cause

of

improper

coupling.