20

Engine

Tractors,

Lawn

and

Gar

den

-

110

and

112

35-16

SM

-2059-(Apr-67)

Piston,

Crankshaft

and

Flywheel

- T

ecu

mseh

CHECKING

CRANKSHAFT

END

CLEAn

AN

CE

\1

u·

Fig

.

]7

-Scaling

PTO

Bear

ing

Invert

engine,

Figure

37.

PTO

end

of

crank-

shaft

must

extend

freely.

Turn

the

crankshaft

until

the

piston

is

at

T.D.C.

Tighten

bearing

retainer

screws

lightly

and

tap

the

flywhe

el

end

of

the

crankshaft

lightly

with

a

mallet

to

seat

bearing.

Afte r

determining

th

e

ga

p

betw

ee

n

the

cover

and

th

e

machin

ed su

rfa

ce

on

cylinder

bl

o

ck

, de -

termine

the

s

him

thickn

e

ss

as

fo

llo

ws to

obtain

the

required

0.002-0.003-in

ch

c r

anks

haft

e

nd

pl

ay.

0.003-inch-clearanc

e

between

cov

e r

and

cyl

-

ind

er

.

+0.003

-1

nc

h-required

end

play.

0.006-inch-shim

thickness

r

eq

ui} 'c'd.

+

O.003-inch-add

half

of

shim

thickness

.l

.

'-

quired

to

compensate

for

gasket

COrtllJl"l', ;SiOll

0.009-inch-use

shim

gaskets

that

total

this

amount.

In

this

case,

uSingtw

oO

.004

toO

.

005-

inch

thi

ck

gaskets

would

allow

correct

crank-

shaft

end

play.

Secure

h

ar

in

g

retainer

with

three

cap

sc

re

ws

with

lock

washers.

Refer

to

"Specifications,"

page

35-18,

f

or

correct

torque

and

torqu

e

screws

accordingly.

.

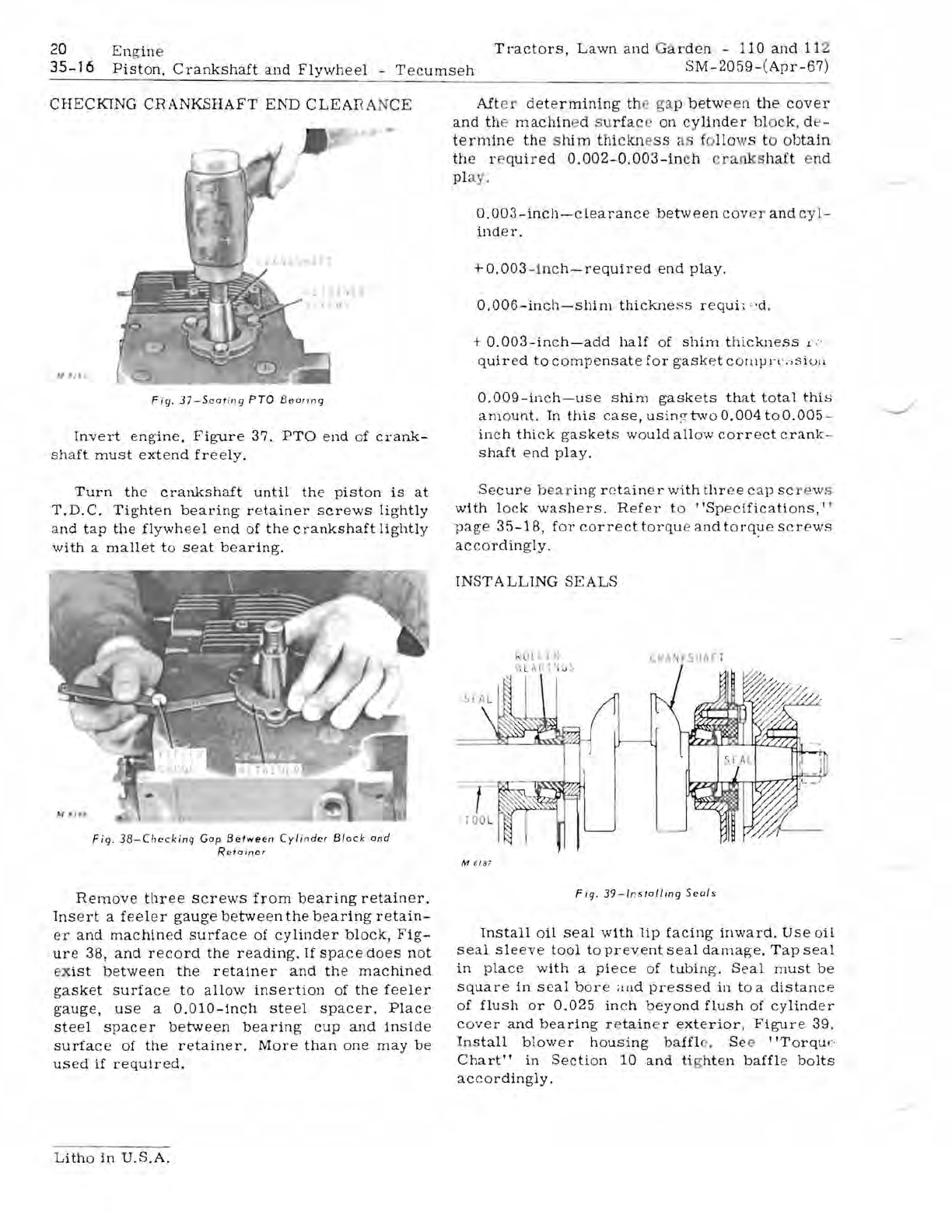

Fig

.

38-CI",cking

Gap

Be/ween

Cylinder

Block

and

Retainer

Remove

three

screws

from

bearing

retainer.

Ins

e

rt

a

feeler

gauge

between

the

bearing

retain-

er

and

machined

surface

of

cylinder

block,

Fig-

ure

38,

and

record

the

reading.

If

space

does

not

ex

ist

between

the

retainer

and

the

machined

gasket

surface

to

allow

insertion

of

the

f

ee

ler

gauge,

use

a

0.010-inch

steel

spacer.

Place

steel

spacer

between

bearing

cup

and

inside

surface

of

the

retainer.

More

than

one

may

be

us

ed

if

required.

INST

A

LLlNG

SE

A LS

kl

H I

Lf.:

nL

A.P

t 'I s)

M

618

7

Fig

.

39-l

ns

/alling

S

eals

Install

oil

seal

with

lip

facing

inward.

Use

oil

seal

sleeve

tool

to

prevent

seal

damage.

Tap

seal

in

place

with

a

piece

of

tubing.

Seal

must

be

square

in

seal

bor

e ;illd

pressed

in

to

a

distance

of

flush

or

0.025

inch

beyond

flush

of

cylinder

cover

and

bearing

r e

tain

e r

exterior,

Figure

39.

Install

blower

housing

baffl

e.

Se

e

"Torqu

e

Chart"

in

Section

10

and

ti

g

hten

baffl

e

bolts

accordingly.

Litho

in

U.S.A.