50

Power

Train

Tractors,

Lawn

and

Garden

-

110

and

112

20-12

4-Speed

Transaxle

SM-2059-

(Apr-57)

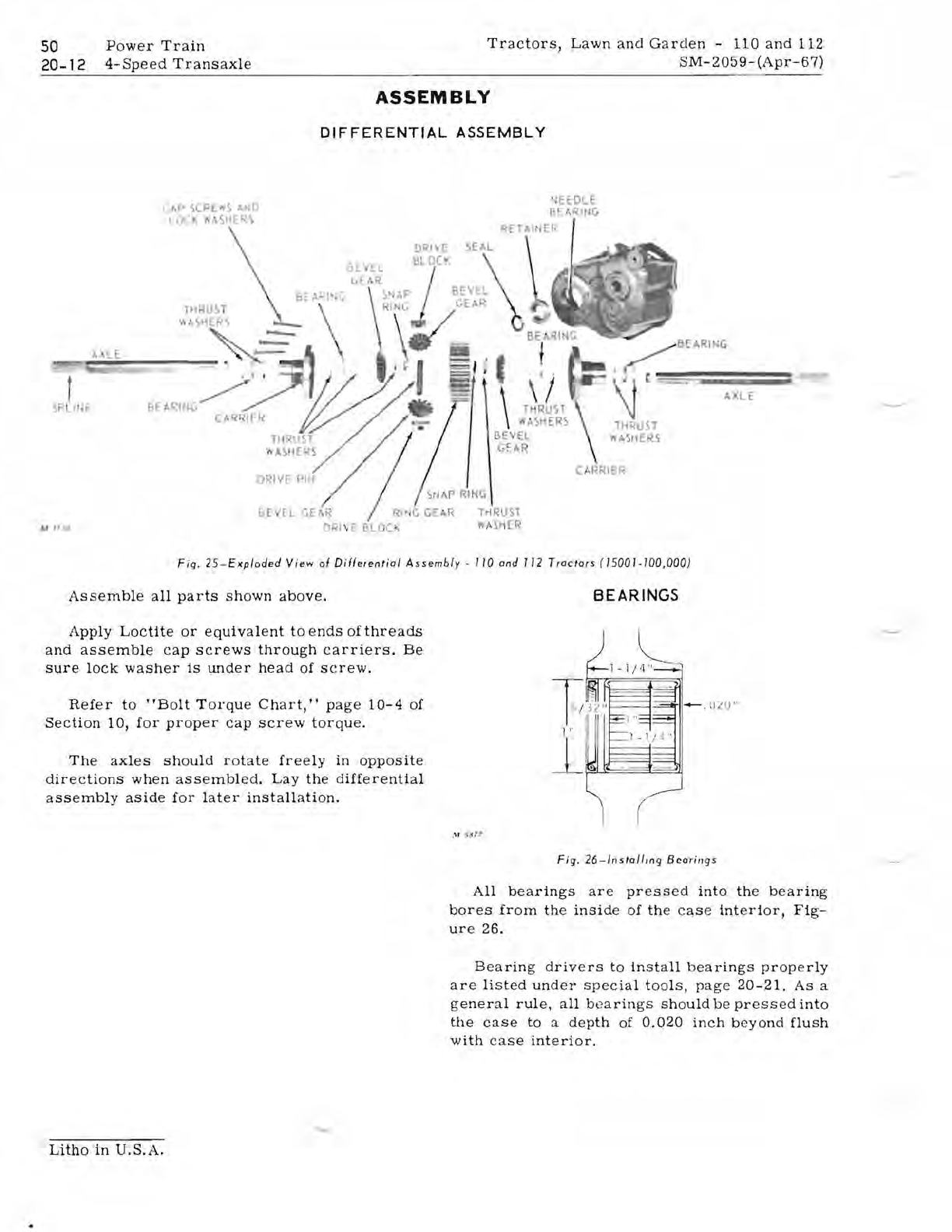

ASSEMBLY

DIFFERENTIAL

ASSEMBLY

(

"p

\CPE

.....

S

"'I~D

DC

....

'••

SlIfR,

RET"I

THRIIST

\\:.

SHER5

\!

PLI,

r.

T

RUST

\

flASHERS

\

BEVEL

GE

AR

~

.'AR"C

\J

A

LE

THRUST

WA~HERS

CARRIER

THRUST

i'll

.

SH

[ R

Fig

.

25-EKploded

View

of

Differential

Assembly·

110

and

112

Tractors

(

15001.100,000

)

r Jl II

Assemble

all

parts

shown

a

bove.

Apply

Loctite

or

equivalent

to

ends

of

threads

and

assemble

cap

s c

rews

through

carriers.

Be

sure

lock

washer

is

under

head

of

s c

rew.

Refer

to

"Bolt

Torque

Chart,"

pa

ge

10-4

of

Section

10,

for

proper

cap

screw

torque.

The

axles

should

rotate

freely

in

opposite

directions

when

assembl

ed.

Lay

the

differential

assembly

aside

for

later

installation.

BEARINGS

(

:w

S

r;

Fig.

26-lnstall

i

ng

Bea

rin

gs

All

bearings

are

pressed

into

the

bearing

bores

from

the

inside

of

the

c

as

e

interior,

Fig-

ure

25.

Bearing

drivers

to

install

bearings

properly

are

listed

under

special

to

o

ls

,

page

20-21.

As

a

general

rule,

all

bearings

should

be

pressed

into

the

case

to

a

depth

of 0.

020

inch

be

yond

flush

with

case

interior.

Litho

in

U.S.A.