30

Fuel

System

Tractors,

Lawn

and

Garden

- 110

and

112

10-4

Carburetor

- 110

Tractor

SM-2059-(Apr-67)

INSTALLING

FLOAT

AND

FLOAT

SHAFT

INSTALLATION

."

t.

J'

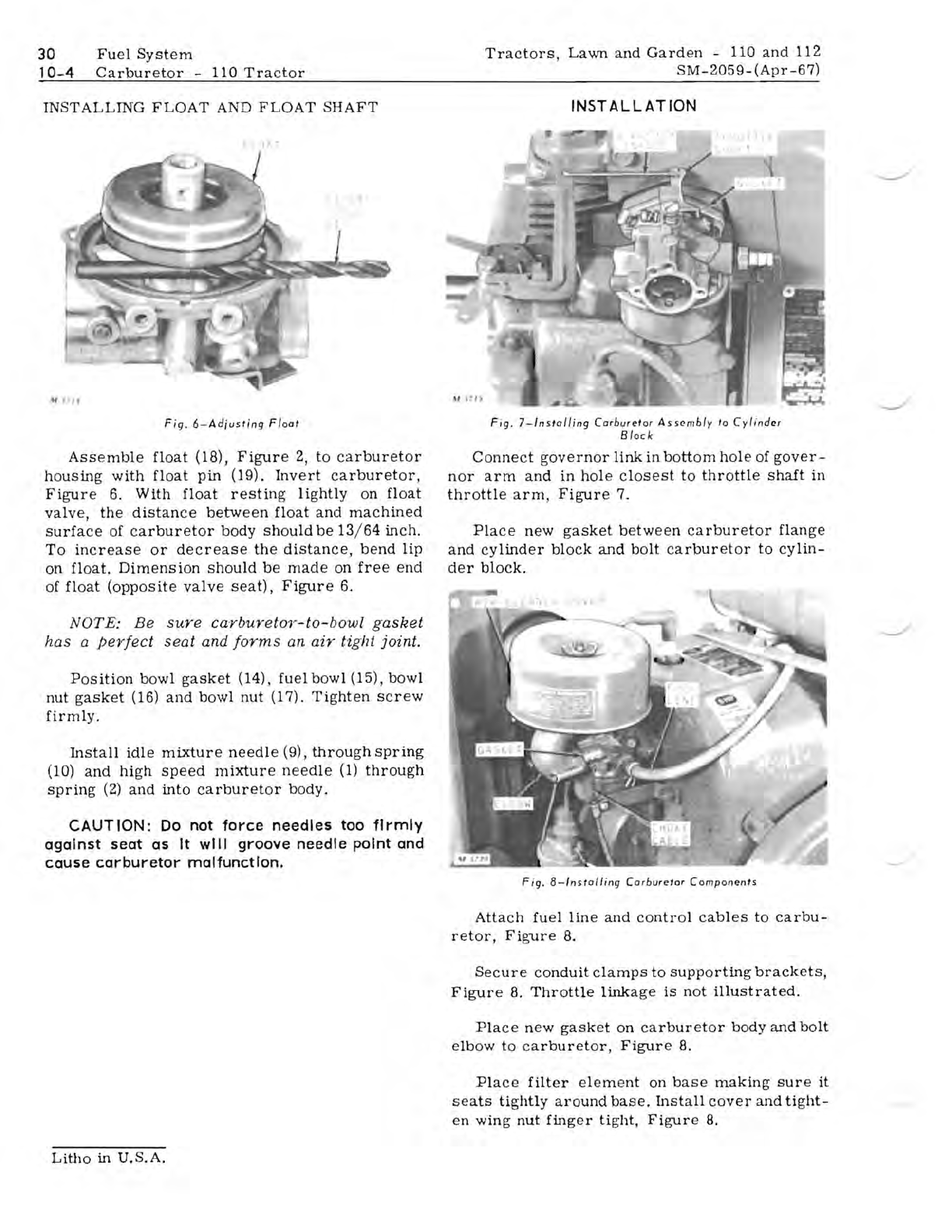

Fig.

6-Ad;u5ting

Float

Assemble

float

(18),

Figure

2,

to

carburetor

housing

with

float

pin

(19).

Invert

carburetor,

Figure

6.

With

float

resting

lightly

on

float

valve,

the

distance

between

float

and

machined

surface

of

carburetor

body

should

be

13/ 64

inch.

To

increase

or

decrease

the

distance,

bend

lip

on

float.

Dimension

should

be

made

on

free

end

of

float

(opposite

valve

seat),

Figure

6.

NOTE:

Be

sure

carburetoy-to-bowl

gasket

has

a

peYfect

seat

and

forms

an

air

tight joint.

Position

bowl

gasket

(14),

fuel

bowl

(15),

bowl

nut

gasket

(16)

and

bowl

nut

(17).

Tighten

screw

firmly.

Install

idle

mixture

needle

(9),

through

spring

(10)

and

high

speed

mixture

needle

(1)

through

spring

(2)

and

into

carburetor

body.

CAUTION:

Do

not force needles

too

firmly

against seat

as

It will groove needle point

and

cause

carburetor

malfunction.

Fig

.

7-ln5tol/ing

Carburetor

Ass~mbly

to

Cylinder

Block

Connect

governor

link

in

bottom

hole

of

gover-

nor

arm

and

in

hole

closest

to

throttle

shaft

in

throttle

arm,

Figure

7.

Place

new

gasket

between

carburetor

flange

and

cylinder

block

and

bolt

carburetor

to

cylin-

der

block.

Fig

.

8-lnstal/ing

Carburetor

Components

Attach

fuel

line

and

control

cables

to

carbu-

retor,

Figure

8.

Secure

conduit

clamps

to

supporting

brackets,

Figure

8.

Throttle

linkage

is

not

illustrated.

Place

new

gasket

on

carburetor

body

and

bolt

elbow

to

carburetor,

Figure

8.

Place

filter

element

on

base

making

sure

it

seats

tightly

around

base.

Install

cover

and

tight-

en

wing

nut

finger

tight,

Figure

8.

Litho

in U.S.A.