Tractors,

Lawn

and

Garden

-

110

and

112

Engine

20

SM-2059-

(Apr-67)

Cy

linder

Head

and

Valves

-

Kohl

er

10

- 7

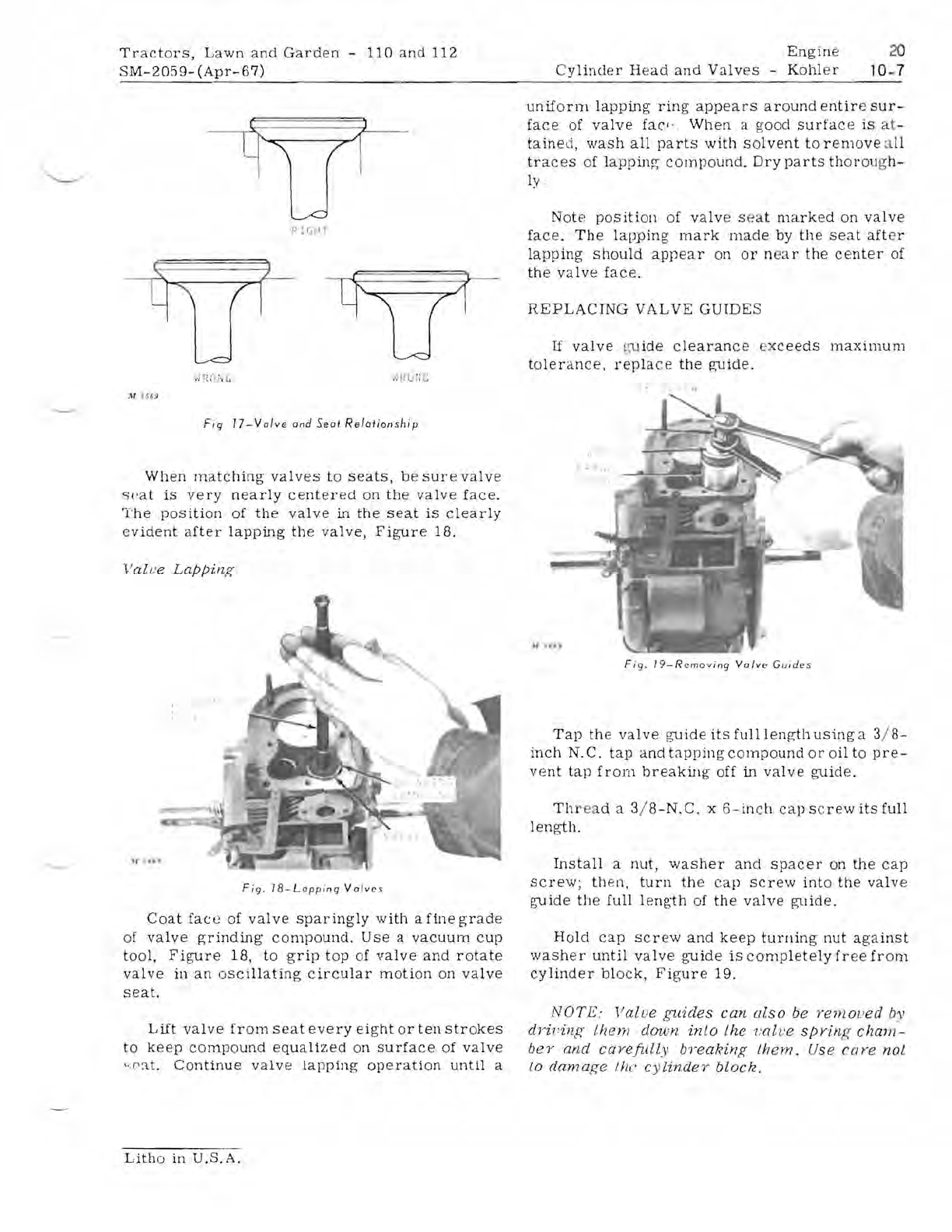

RI

r.

HT

Fig

17-Valve

and

Seat

Relat

ions

hip

When

matching

valves

to

seats,

be

sure

valve

~cat

is

very

nearly

centered

on

the

valve

face.

The

position

of

the

valve

in

the

seat

is

clearly

evident

a

fter

lapping

the

valve,

Figure

lB.

Value

Lappinf{

Fig,

18-Lapping

Valves

Coat

face

of

valve

sparingly

with

a

fine

grade

of

valve

p;rinding'

compound,

Use

a

vacuum

cup

tool,

Figure

1B,

to

grip

top

of

valve

and

rotate

valve

in

an

oscillating

circular

moti

on

on

valve

seat.

Lift

valve

from

seat

every

eight

or

ten

strokes

to

keep

compound

equalized

on

surface

of

valve

c

.('at.

Continue

valve

lapping

operation

until

a

Litho

in

U.S.A.

uniform

lapping

ring

appears

around

entire

sur-

face

of

valve

facl

.'

When

a

good

surface

is

at-

tained,

wash

all

part

s

with

solvent

to

remove

a

ll

traces

of

lapping

compound.

Dry

parts

thol'ol

lO'h

-

ly

Not

e

pOSition

of

valve

s e

at

marked

on

valve

face.

The

lapping

mark

made

by

the

seat

after

lapping

should

appear

on

or

n

ea

r

the

center

of

the

valve

face.

REPLACING

VALVE

GUIDES

If

valve

gu

ide

clearance

ex

ceeds

maximum

tolerance.

replace

the

guide,

F

ig.

19-Rcmo

v

ing

Val

ve

Guides

Tap

the

valve

guide

its

full

I

en

i-,rt

b

using

a 3/ B-

inch

N.

C,

tap

and

t

app

ing

compound

or

oil

to

pre-

vent

tap

from

breaking

off

in

valve

guide.

Th

r

ea

d a 3/

8-N.

C, x 6 -

inch

cap

s

cre

w

its

full

length.

Install

a

nut,

washer

and

sp

acer

on

the

cap

screw;

then,

tUrn

the

ca

p

SCrew

into

the

valve

guide

the

full

leng·th

of

the

valve

guide.

Hold

cap

SCrew

and

keep

turning

nut

against

washer

until

valve

gUide

is

completelyfr

e

efrom

cylinder

blOCk,

Figure

19.

NOTE:

Valve

guides

can

also

be

renlOl

.'

ed

by

dririnp:

them

down

into

the

valve

spY/n

f{

cham-

bey

and

carefunv

breakinf{

them.

Use

co

re

not

to

damage

the

cylindey

block.