Tractors,

Lawn

and

Garden

-

110

and

112

Engin

e

20

SM

-

2059

-(Apr-57)

Piston.

Crankshaft

and

Flywheel

-

Kohler

15-9

,

It

:

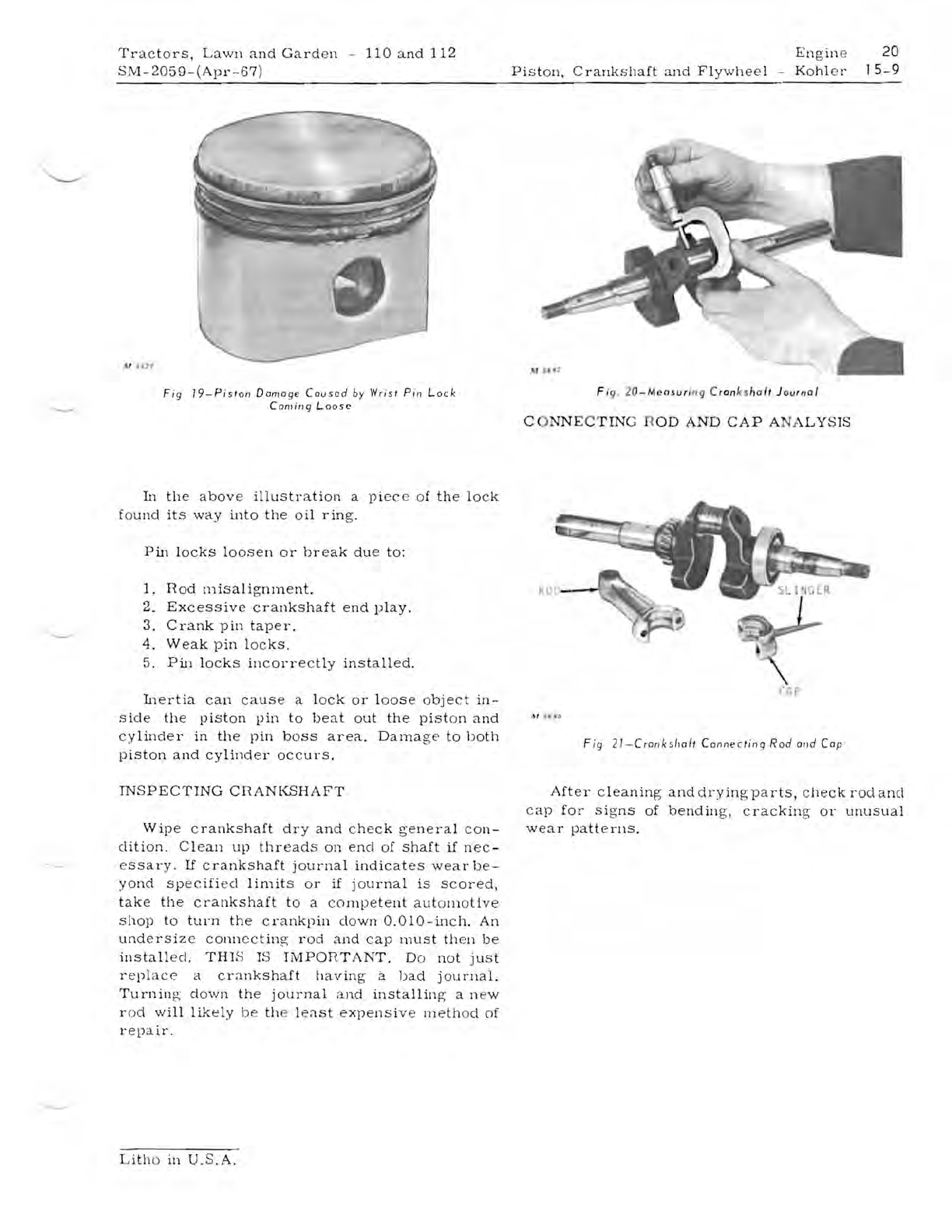

Fig

79-Pisl

on

Damage

Caused

by

Wrisl

Pi

n L

ock

C

oming

Loose

In

the

above

illustration

a p

iece

of

the

lock

fo

und

its

way

into

the

oil

ring.

Pin

locks

loosen

or

break

due

to:

1.

Hod

misalignment.

2.

Excessive

crankshaft

end

play.

3.

Crank

pin

taper.

4.

Weak

pin

locks.

5.

Pin

locks

incorr

ectly

installed.

Inertia

can

cause

a l

ock

or

loose

object

in-

side

the

piston

pin

to

beat

out

the

pist

on

and

cylinder

in

the

pin

boss

area.

Dama

ge

to

l

)o

th

piston

and

cylinder

OCCurS.

INSPECTING

CRANKSHAFT

Wipe

crankshaft

dry

and

check

general

con-

clition.

Clean

up

thr

eads

on

end

of

shaft

if

nec-

essary.

If

crankshaft

journal

indicates

wea

r

be-

-

yond

specified

limit

s

or

if

journal

is

scored,

take

the

crankshaft

to

a

competent

aut

om

otive

shop

to

turn

th

e

crankpin

down

O.OlO-inch.

An

underSize

connectin~

rod

and

cap

must

then

be

installed

.

THIS

IS

IMPORT

ANT.

Do

not

just

replace

a

crankShaft

having

a l

)a

d

journal.

Turnin

g

down

th

e

journal

and

installin

g a

new

r

od

will

likely

be

th

e

least

expens

i

ve

meth

od of

repair.

Fi

g. 2

0-

Ml>o

s

ur

l

n9

Cr

an

ks

hall

Jour

na

l

C

NNECTING

R

OD

AND

CAP

A ALYSIS

rAP

M

se,iO

F

ig

27

-Cronks/'all

Ca

nnec

ling

Rod

and

Cap

After

cleaning

anddryingparts,

checkroc\ancl

cap

for

signs

of

bending,

cracking

or

unusual

wea

r

patterns.

Litho

in

U.S.A.