20

Engine

15-16

Piston,

Crankshaft

and

Flywheel

-

Kohler

ATTACHING

ROD

TO

CRANKSHAFT

Fig

3?-Rod

and

Crankshaft

Assembl

y

After

piston

assembly

is

installed,

place

block

on

end

and

oil

connecting

rod

and

crank

pin.

Be

Sure

that

match

marks

on

connecting

rod

and

cap,

Figure

39

,

al'e

aligned

anclface

flywhe

el

side

of

eng

ine

.

Attach

connecting

rod

cap,

lock

plate

and

cap

scr

ews

to

the

connecting

rod.

Use

a

torque

wrench

to

tighten

connecting

rod

cap

screws

to

220-inch

pounds.

Back

off

screws

and

tighten

to

200-inch

pounds.

This

two

step

procedure

will

assure

a

tight

fit

of

rod

to

crankshaft

and

avoids

possibility

of

screws

tightening

in

threads

while

rod

remains

loose

on

crankshaft.

IA1PORT/lNT'

Bend

lips

of

lockpla/e

/0

yod

cap

scyew

heads

to

pvevenLscyewsfronz

loosen-

ing.

INSTALLING

OIL

PAN

ON

BLOCK

Place

a

new

g'asket

Oll

oil

pan.

Position

oil

pan

to

match

cylinder

block.

Figure

40.

Place

coil

bracket

on

front

of

cylinder

block.

Install

two

3/8

x

1-1/4-incl1

cap

Screws

through

coil

bracket

and

engine

block.

Install

two

3/8

x

I-inch

cap

screws

through

rear

of

engine

block.

Hefer

to

Torque

Chart,

Section

10

and

torque

cap

screws

accordingly.

Tractors,

Lawn

and

Garden

-

110

and

112

SM-2059-(Apr

-67)

F

ig.

40-0il

Pan

an d

Ga

sket

A

ssc'mu/y

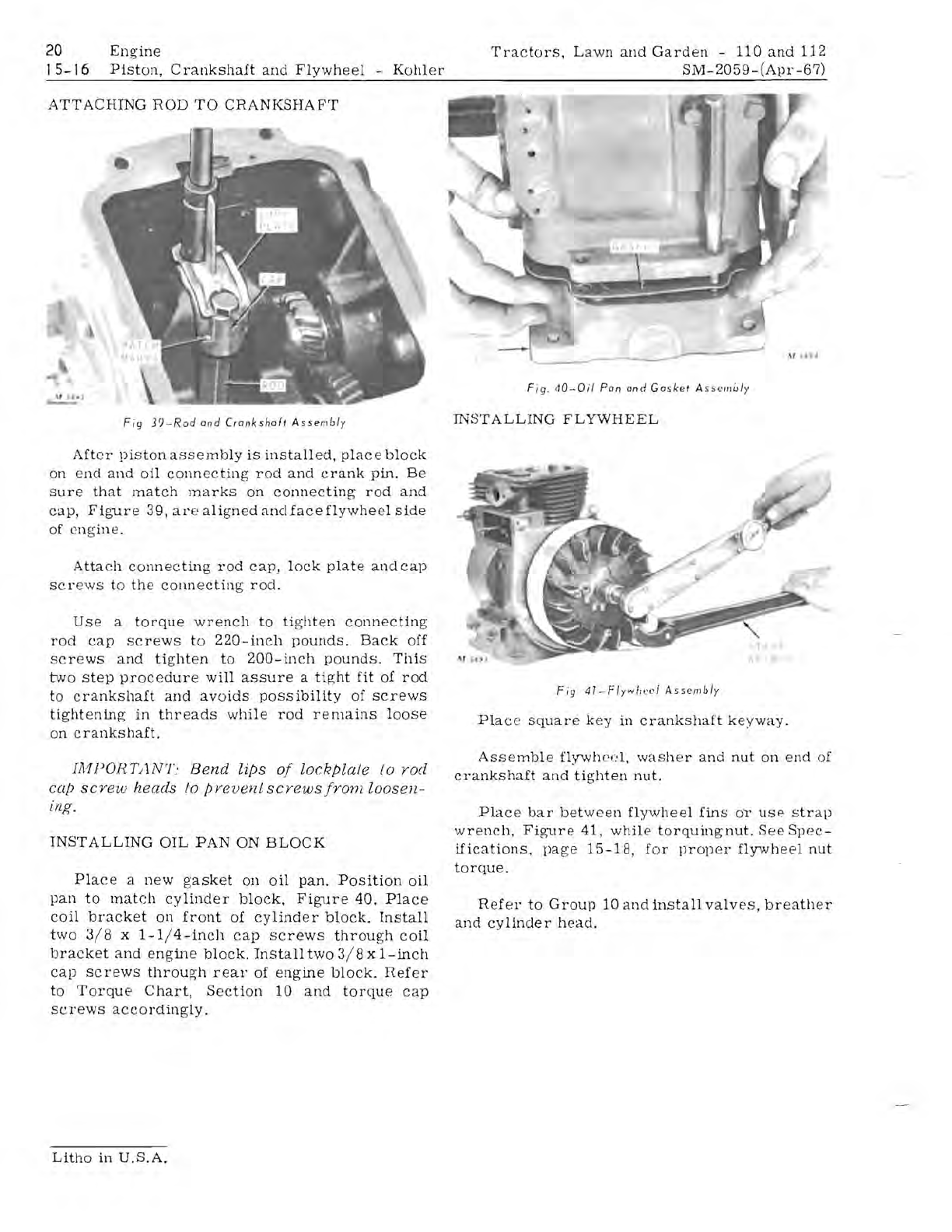

INSTALLING

FLYWHEEL

Fig

41-Flywlll'cI

A

ssemb

ly

Plac

e

square

k

ey

in

crankshaft

keyway.

Assemble

flywh

cf.'

l.

washer

and

nut

on

end

of

crankshaft

and

tighten

nut.

Place

bar

between

flywheel

fins

01'

use

strap

wrench,

Fig'ure

41,

while

torquing'nut.

See

Spec-

ifications,

page

15

-18,

for

prop

er

flywheel

nut

torque.

Refer

to

Group

10

and

install

valv

es,

breather

and

cylinder

head.

Litho

in

U,S.A.