Tractors,

Lawn

and

Garden

-

110

and

112

Engine

20

SM-2059-

(Apr-

67)

Piston,

Crankshaft

and

Flywheel

-

Tecumseh

35-11

INSPECT

ING

AND

RE

PAIR

ING

BLOCK

After

thoroughly

cleaning

the

block,

check

it

for

cracks.

Cr

acks

not

visible

to

the

naked

eye

may

be

d t

ected

by

coating

the

suspected

area

with

a m

ix

ture

of

25

per

cent

kerosene

and

75

per

cent

li

g

ht

engine

oil.

Wip

e

the

part

dry

and

immediately

apply

a

coati

ng

of

zinc

oxide

dissolved

in

wood

alcohol.

li

a

cr

a

ck

is

pretl811t,

the

coating

will

become

di,scolored

at

the

de

fective

area.

Replace

the

blo

ck

if

ra

cke

d. N OTE.' A

short

bl

oc

ll

is

a1'

uil-

ab

le

fay

sen'ice.

Fig.

24-Meosuring

Cylinder

Bore

Use

a

telescoping

gauge

anc!

micrometer

to

measure

bore

in

two

places,

at

top

and

bottom

of

ring

travel

area.

Out-of-round

dimension

is

the

difference

between

dimensions

A

and

B.

Cyl-

inder

wall

taper

is

the

difference

between

dimen-

sion

A

at

the

top

and

dimension

A

at

the

bottom

of

cylinder

bore.

See

"Specifications,"

page

35-18,

for

wear

tolerance.

DEGLAZING

CYLINDER

BORE

Deglazing

is

not

intended

to

remove

any

ap-

preciable

amount

of

metal

from

the

bore,

but

rather

to

clean

up

and

provide

the

proper

sur-

face.

A

proper

bore

surface

feels

smooth,

but

has

a

cross-hatch

pattern

of

micro-scratches

which

can

be

seen.

This

finish

will

allow

the

new

rings

to

conform

to

the

cylinder

bore,

This

fin-

ish

also

retains

a

,small

film

of

oil

to

provide

ring

lubrication

for

the

ring

surface

and

prevents

scoring.

Litho

in

U.S.A.

[

..

uL

I j

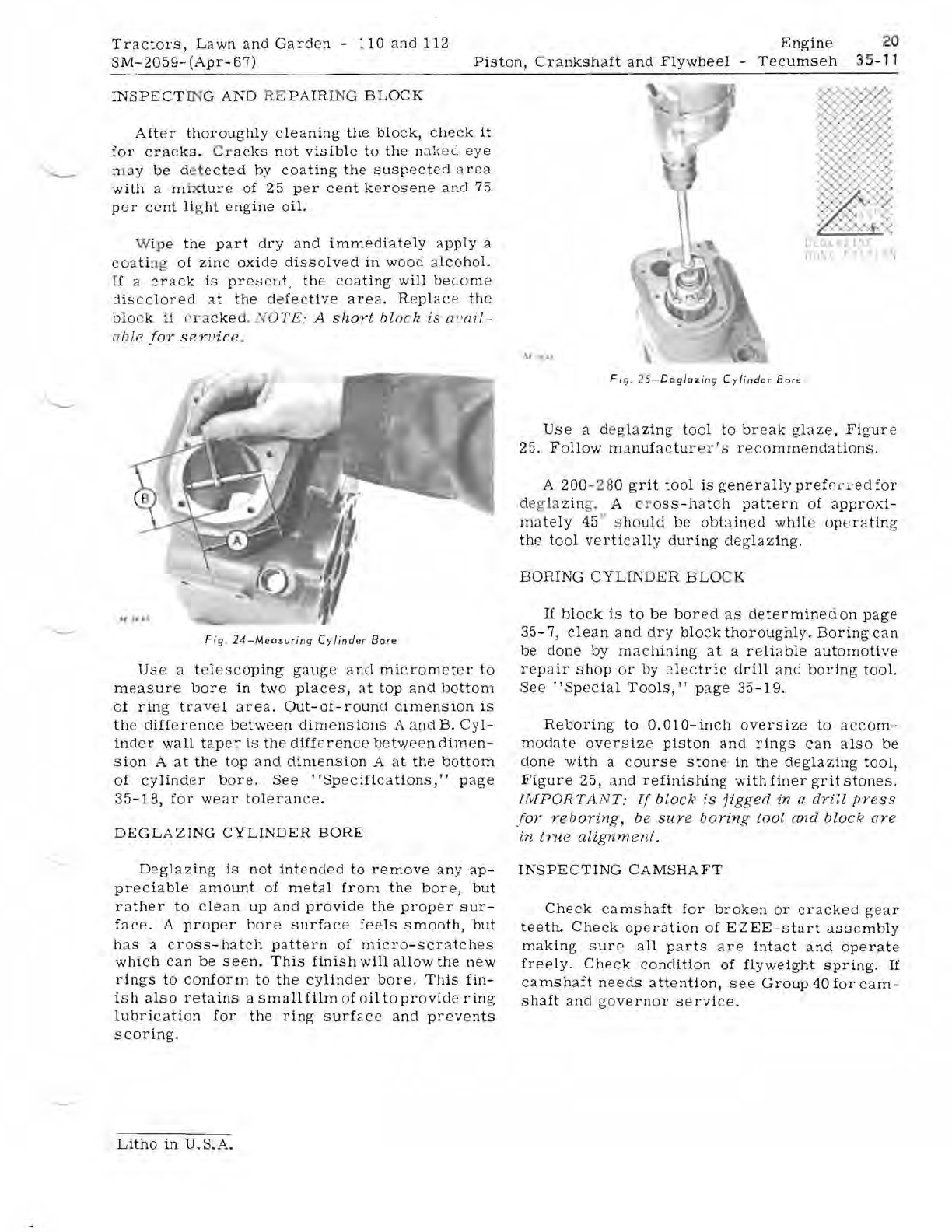

F,o

, 25-

Deglazi/lg

Cylinder

Bore

Use

a de

gl

a

zing

tool

to

break

glaze,

Figure

25,

Follow

m a

nufactur81

" s

recommendations.

A

200

-2

80

grit

tool

is

generally

prefr:J:J.ed

for

de

g

la

zin

g. A cr

oss-hatch

pattern

of

approxi-

m a

tely

45 " s

hould

be

obtained

while

operating

the

tool

vertically

during

cleglazlng.

BORING

CYLINDER

BL

OCK

If

block

is

to

be

bored

as

determined

on

page

35-7,

clean

and

dry

block

thoroughly.

Boring

can

be

done

by

machining

at

a

reliable

automotive

repair

shop

or

by

electric

drill

and

boring

tool.

See

T!

Special

Tools,"

page

35-19.

Reboring

to

O.OlD-inch

oversize

to

accom-

modate

oversize

piston

and

rings

can

also

be

done

with

a

course

stone

in

the

deglazing

tool,

Figure

25,

and

refinishing

with

finer

grit

stones.

li'vIPORTANT:

If

block

is

jigged

in

a

drill

press

for

reboring,

be

sure

boring

Lool

and

block

are

in

Lnte

alignment.

INSPECTING

CAMSHAFT

Check

camshaft

for

broken

or

cracked

gear

teeth.

Check

operation

of

EZEE-start

assembly

making

sure

all

parts

are

intact

and

operate

freely.

Check

conc\ition

of

flyweight

spring.

If

camshaft

needs

attention,

see

Group

4D

for

cam-

shaft

and

governor

service.