20

Engine

Tractors,

Lawn

and

Garden

-

110

and

112

25-2

General

Information

-

Tecumseh

SM-

2059-

(Apr-

6 7)

ENGINE

ANALYSIS

PRELIMINARY

ENGINE

CHECKS

A

complete

guide

for

diagnosing

engine

mal-

functions

appears

on

page

25-4.

However,

the

majority

of

engine

trouble

reports

are

of

a

minor

non-chronic

nature

and

are

usually

due

to

elec-

trical

or

fuel

system

difficulties.

First

make

the

c

hecks

listed

below

to

isolate

the

majority

of

engine

problems.

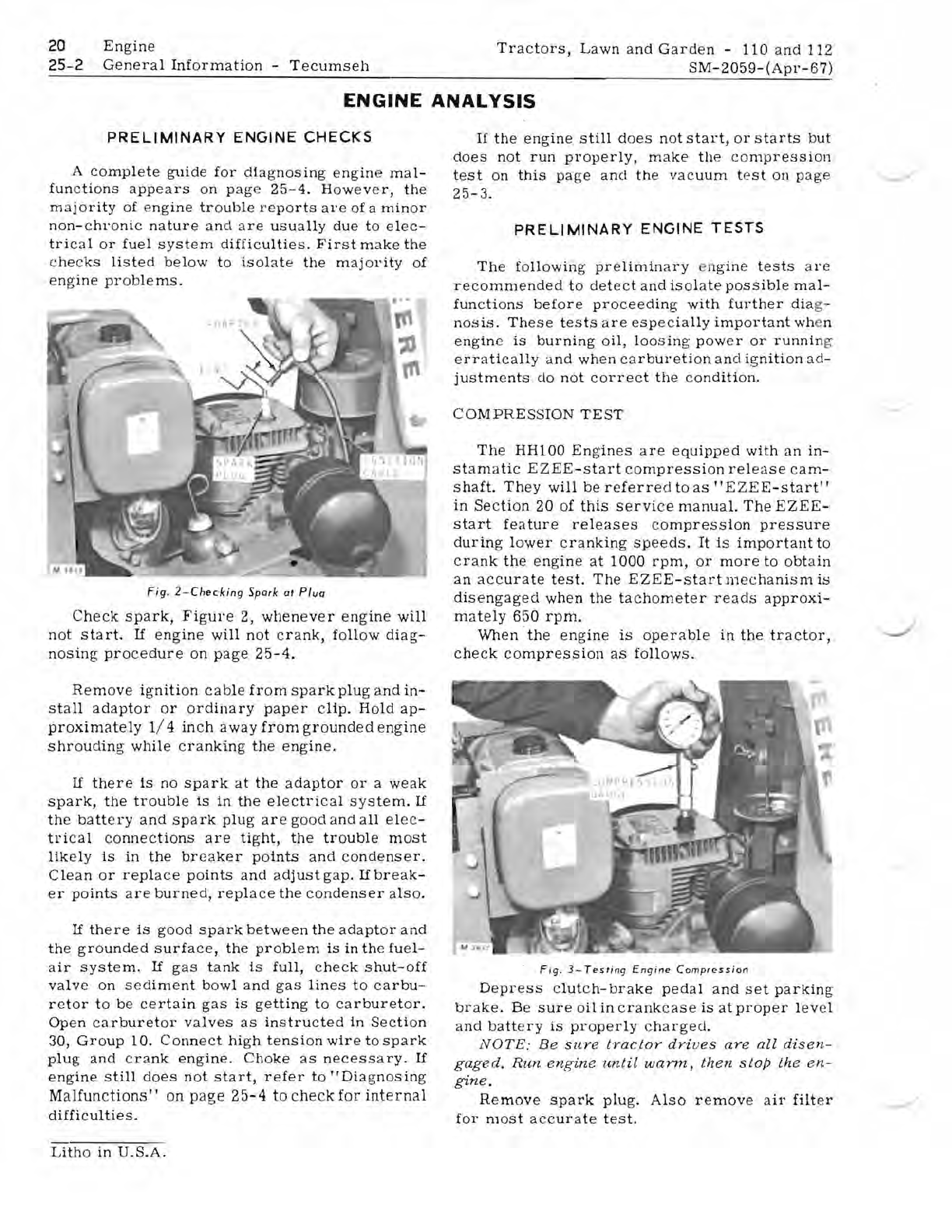

Fig

.

2-Checking

Spork

ot

P/uq

Check

spark,

Figure

2,

whenever

engine

will

not

start.

If

engine

will

not

crank,

follow

diag-

nosing

procedure

on

page

25-4.

Remove

ignition

cable

from

spark

plug

and

in-

stall

adaptor

or

ordinary

paper

clip.

Hold

ap-

proximately

1/4

inch

away

from

grounded

engine

shrouding

while

cranking

the

engine.

If

there

1s

no

spark

at

the

adaptor

or

a

weak

spark,

the

trouble

is

in

the

electrical

system.

If

the

battery

and

spark

plug

are

good

and

all

elec-

trical

connections

are

tight,

the

trouble

most

likely

is

in

the

breaker

points

and

condenser.

Clean

or

replace

points

and

adjust

gap.

If

break-

er

points

are

burned,

replace

the

condenser

also.

If

there

is

good

spark

between

the

adaptor

and

the

grounded

surface,

the

problem

is

in

the

fuel-

air

system.

If

gas

tank

is

full,

check

shut-off

valve

on

sediment

bowl

and

gas

lines

to

carbu-

retor

to

be

certain

gas

is

getting

to

carburetor.

Open

carburetor

valves

as

instructed

in

Section

30,

Group

10

.

Connect

high

tension

wire

tospark

plug

and

crank

engine.

Choke

as

necessary.

If

engine

still

does

not

start,

refer

to

"Diagnosing

Malfunctions"

on

page

25-4

to

check

for

internal

difficulties.

If

the

engine

still

does

not

start,

or

starts

but

does

not

run

properly,

make

the

compression

test

on

this

page

and

the

vacuum

test

On

page

25-3.

PRELIMINARY

ENGINE

TESTS

The

following

preliminary

e n

gine

tests

are

recommended

to

detect

and

isol

a

te

possible

mal-

functions

before

proceeding

with

further

dia

g-

nosis.

These

tests

are

especially

important

wh

e n

engine

is

burning

oil,

loosing

power

or

runni

ng

erratically

and

when

carburetion

and

ignition

ad-

justments

do

not

correct

the

condition.

COMPRESSION

TEST

The

HHIOO

Engines

are

equipped

with

an

in-

stamatic

EZEE-start

compression

release

cam-

shaft.

They

will

be

referred

to

as

"EZEE-start"

in

Section

20

of

this

service

manual.

The

EZEE-

start

feature

releases

compression

pressure

during

lower

cranking

speeds.

It

is

important

to

crank

the

engine

at

1000

rpm,

or

more

to

obtain

an

accurate

test.

The

EZEE-start

mechanism

is

disengaged

when

the

tachometer

reads

approxi-

mately

650

rpm.

When

the

engine

is

operable

in

the

tractor,

check

compression

as

follows.

Fig.

3-

Testing

Engine

Compression

Depress

clutch-brake

pedal

and

set

parking

brake.

Be

sure

oil

in

crankcase

is

at

proper

lev

el

and

battery

is

properly

Charged.

NOTE:

Be

sure

tractor

drives

are

all

disen-

gaged.

Run

engine

until

warm.,

then

s top

the

en-

gine.

Remove

spark

plug.

Also

remove

air

filter

for

most

accurate

test.

Litho

in

U.S.A.