20

Engine

Tractors,

Lawn

and

Garden

-

11

0

and

112

10-6

Cylinder

Head

and

Valves

-

Kohler

SM-2059-

(Apr-67)

RECONDITIONING

OR

REPLACING

VALVES

Vali'e

Guides

Fig.

14-Measuring

Valve

Guide

s

and

SIems

Clean

th

e

valve

guides

first

to

assure

valve

ali

gnme

nt

when

cutting

valve

seats.

Use

valve

guide

c

leaner

to

clean

inside

of

valve

guide.

Then

measure

LD.

of

valve

guide.

and

O.D.

of

valve

stem,

Figure

14.

Refer

to

Specifications,

page

10-11,

for

clearance.

Re-

place

and

ream

guides

as

n

ecessa

ry.

Vall'e

S

eal

s

Broken

or

wor

n

exhaust

valve

seats

(i

ns

er

t)

may

be

replaced.

See

page

J

0-8.

Th

ey

are

either

stellite

Or

molychrome

nickel.

The

int

a

ke

valve

seat

is

ma

chi1\ed

into

the

cylinder

block

.

When

required.

an

intake

valve

se

at m

ay

be

installed.

See

page

10-8

.

Th

e

valve

seating

surface

"A,"

Figure

15,

should

be

he

ld

as

close

to

1/ 32

inch

as

possible.

Seats

with

more

than

1/

16-inch

seating

surface

should

be

narrowed

(

cu

t

back)

with

30°

cutters,

II

E,

" F igu r e 15.

The

valve

seat

angle'

'B"

depends

upon

valve

face

angle

"C."

New

valves

have

a 45 °

face.

Recondition

valve

seats

with

45°

cutters

and

lap

valves.

See

page

10-7.

/

M

5567

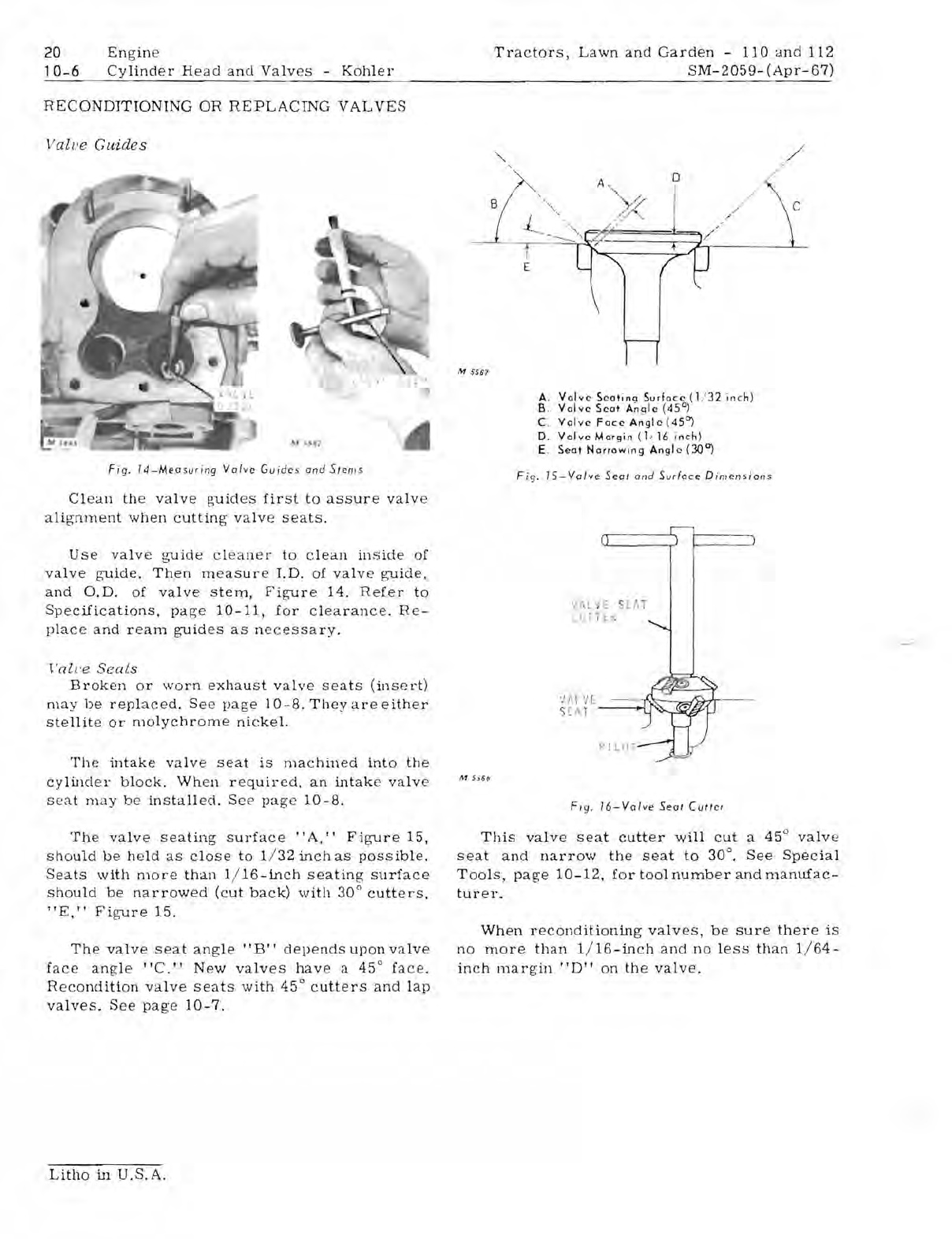

A.

Valve

Sealinq

Surface

(1/3

2

inch)

B.

Valve

Scat

A~91c

(45

0

)

C.

Valve

Face

Angle

(4

5")

D.

Valve

Margin

(1

, 16

inch)

E.

Seat

Narrowing

Angl e (3O")

Fig.

15-Va/ve

Seat

and

Surface

Dimension

s

VALlE

S

EII

T

r.U

i 1

ER

'J

II i

'iL

-=

=

::N~'CG@i'i

-

') [

11

]

I'

lilT

Fig.

16-Val

ve

Seal

Culler

This

valve

seat

cutter

will

cut

a

45°

valve

seat

and

narrow

the

seat

to

30°.

See

Special

Tools,

page

10-12,

for

tool

number

and

manufac-

turer.

When

reconditioning

valves,

be

sure

ther

e

is

no

more

than

1/

16-inch

and

no

less

than

1/64-

inch

margin

liD"

on

the

valve.

Litho

in

U.S.

A.