40

Electrical

System

Tractors,

Lawn

and

Garden

-

110

and

112

15-10

Charging

System

SM-2059-

(Apr-57)

REPAIR

MOTOR

-G

ENERATOR

Brushes

1 -

Motor-Generator

Complete

2 -

Commutator

End

Frame

3 -

Commutator

End

Bearing

4 -

Bru.h

(2

used)

5 -

Brush

Arm

(2

used)

6 -

Bru

s h

Spring

(2

used)

7 -

Armature

8 -

L.H.

Field

Coil

(3 /

16

"

OD

Wire)

9 -

R.H.

Field

Coil

(3/32"

OD

Wire)

10

-

Drive

End

Bearing

11

-

Drive

End

Frame

12 -

Thru

Bolt

(2

used)

13 -

Pulley

14 -

Shaft

Washer

15

-

Shaft

Nut

16

-

Machine

Screw

(2

used)

Fig

.

13-Expfodcd

View

of

Motor-Generator

C

leaning

Parts

Disassemble

motor-generator

and

clean

parts

with

compressed

air

and

a

dry

cloth.

Never

clean

parts

in

a

degreasing

tank

or

by

use

of

degreas

ing

compounds

since

this

might

damage

insulation

so

that

a

short

or

ground

would

subsequently

develop.

.

'1

,;

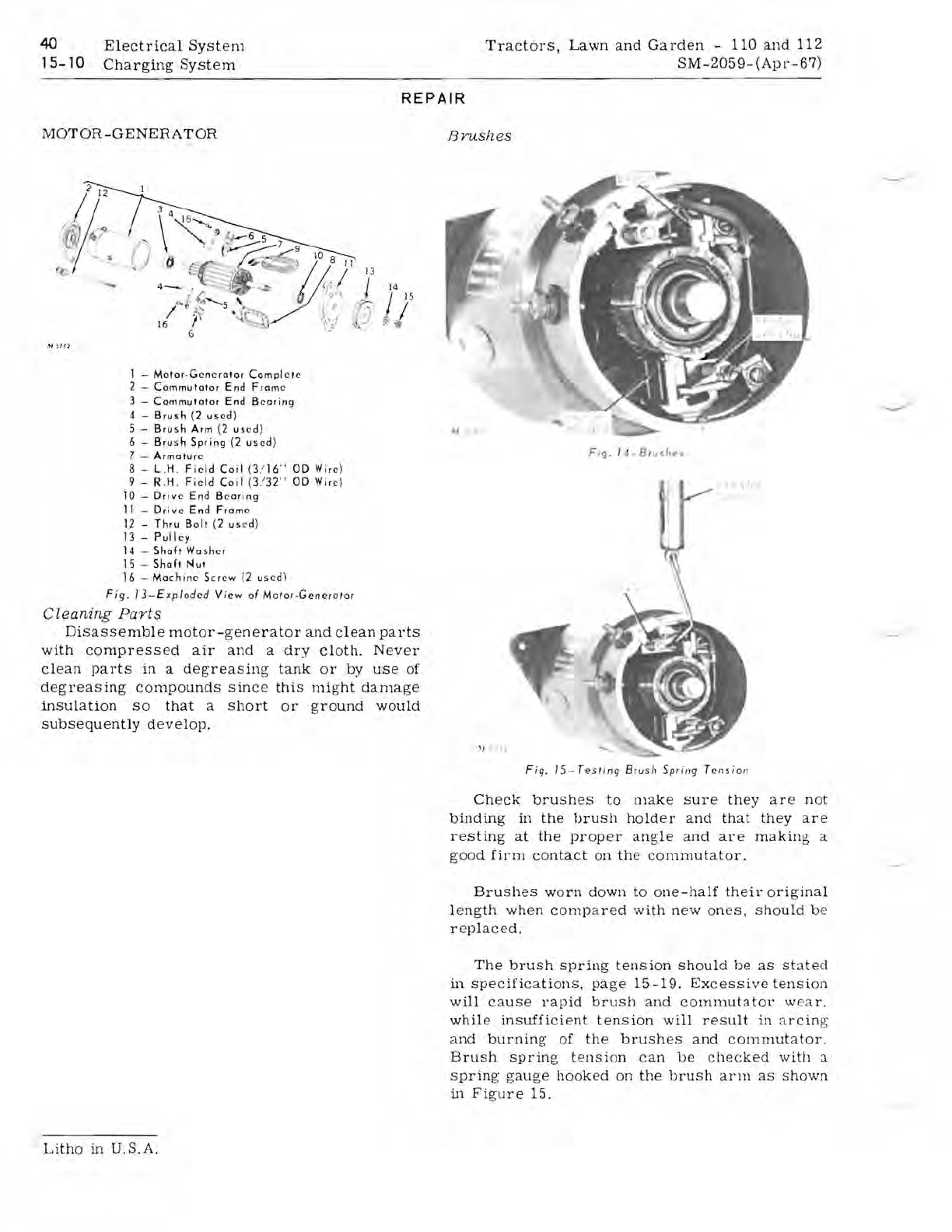

Fig.

15 -

Testing

Brush

Spring

T

ens

ion

Check

brushes

to

make

sure

they

are

not

binding

in

the

brush

holder

and

that

they

are

resting

at

the

proper

angle

a

nd

are

making

a

good

firm

contact

on

the

commutator.

Brushes

wo

rn

down

to

one-half

their

original

length

when

comp

a

red

with

new

ones

,

should

be

replaced.

The

brush

spring

tension

should

be

as

stated

in

specifications,

page

15-19.

Excessive

tension

will

cause

rapid

brush

and

cornmutator

w

ea

r.

while

insufficient

tension

will

result

in

arcing

and

burnin

g

of

the

brushes

and

commutator.

Brush

spring

tensi

on

can

be

checked

with

a

spring

gauge

hooked

on

the

brush

arm

as

Shown

in

Figure

15.

Litho

in

U.

S.

A.