20

En~ine

Tractors

, L

aw

n

and

Ga r

de

n -

110

and

112

15-6

Piston,

Cr

a

nk

s

haft

an

d

Flywhee

l - Ko

hler

PISTON

HING

ANALYSIS

-

Co

ntin

ued

H

.'"

Fi

g.

12-Cl

eol1ing

Ring

Grooy

",

SM

-2059-

(Apr

- 57)

" , . ' j

F

iy.

) I-

Wor

n O

il

Ring

s

Wh

ich

Can"o'

P,oy

/de

Oil

C

o",rol

Ha

ils

of

theoilringarew

o

rndownto

the

steel

e

xp

a

nd

er

spac

e r

an

d

th

e

oil

ring

s

urfac

e

is

worn

flat.

This

can

only

come

from

cy

linder

wall

contact

after

much

use

and

possH)

le

entry

of

abrasives

.

Comp

r e

ssion

rin

gs

will

also

be

worn

thin.

Badly

worn

o

il

rinRs

wi

ll

hav

e:

1.

Extra

lar

ge

g:a

p.

2. Low

tensi

on.

INSPECTING

PISTON

R

emuve

deposits

[rom

piston

surf

a

ces.

Cl

ean

h'l

Jrl1

a

nci

varnish

[rom

th

e

piston

skirt.

Do

not

use

a

caustic

cleaning

sol

ution

or

a

wire

brush

to

clean

pistons.

Be

s

ur

e

the

o

il

rin

g-

hok

::;

arc

c

ll

·

an

.

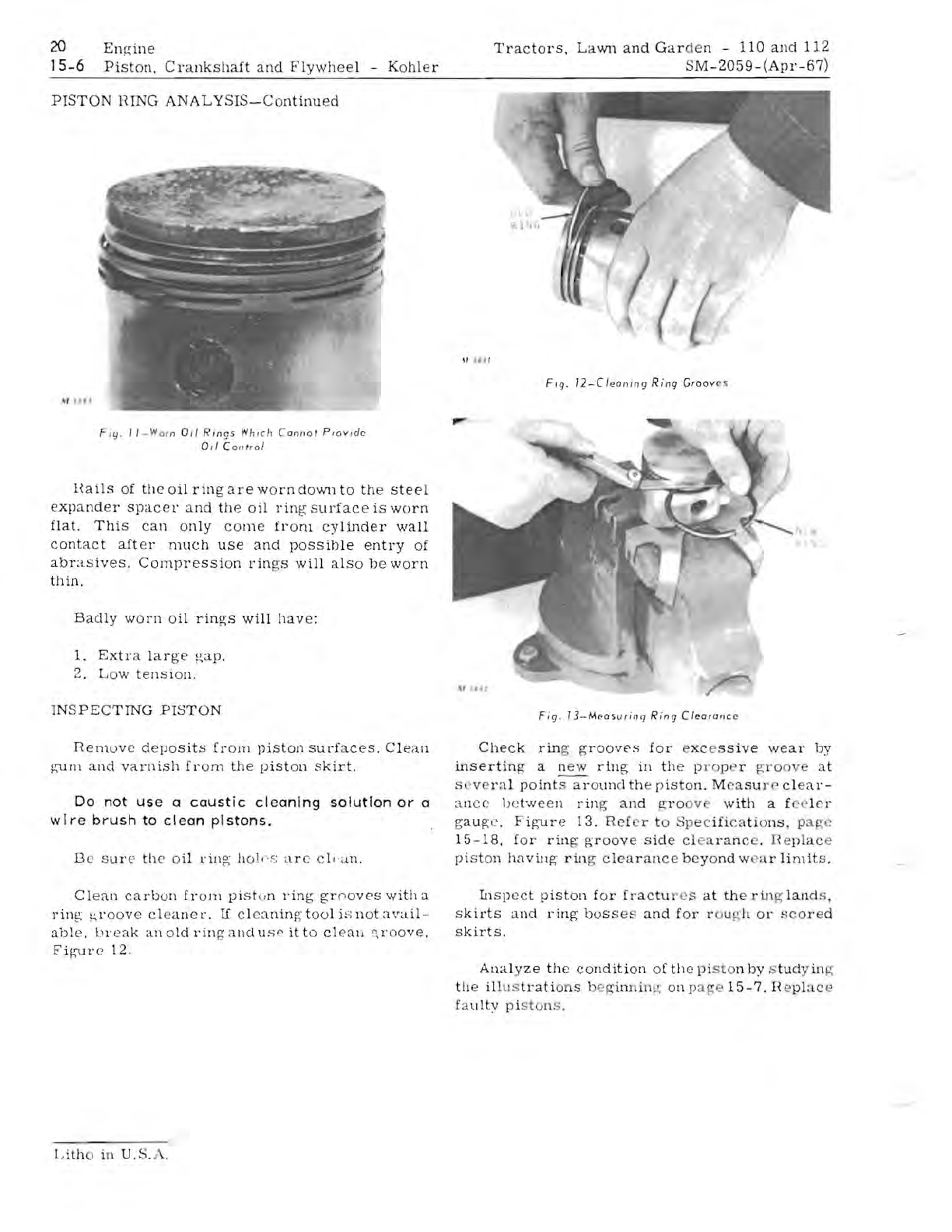

Clean

carbo

n

fr

ol11

pist

on

ring

grnoves

with

a

ring. g r

oove

cleaner.

If

c le3.ning t

oo

l

isnotavail-

abl

e . lw

ea

k

an

old ring: ancl u

s'"

it to

C1e3.11

!:';roove.

Fihrure 12.

F

ig.

13-Moasuli,,

'l

R

ing

CI

<>ol

on

e

<>

Check

rin

g gr

ooves

for

xc

ss

ive

wear

by

inserting-

a n

ew

rin

g in

th

e p

re

per

graD

e at

s 've n

ll

pOint a r o

und

th

e

piston

. M

ea

su

r c l

ea

r-

3.

Il

CC

be

tween

rin

g

and

f

!TO

OV

with

a f e1ot'

g

au

gl:>,

Figure

13 .

Ref

er to

'pec

if

iea

t

io

ns

,

p

a~e

15- 18.

[or

rin

g gr

oove

side

cl

ea

ranc

. n

eplac

e

pisto

n havi.llg-

rin

g

cl

earan

ce

beyo

nd

we r

li

mits.

In

spec

t

piston

f

or

[ra

c

tu

es

at

the

ri.ng

lan

d

s,

s

kirts

and

ring

bosse

s

and

for r ough

or

score

d

sl<irts.

Anal

yz

e

the

condition

o[

th

e

pi

s

to

n

by

s

tu

cly in g

th

e

ill

us

tr

at

i

on

s 1 e

f.",'

in

nin

g;

on p

age

15-7

.

:8

epl

ac

e

faulty

pi

stons.

Litho

in

U.

S.A.