Greensmaster 3320/3420Page 6 - 72Electrical System

Turf Guardian

TM

Leak Detector Oil Level Sensor (If Equipped)

NOTE: The Turf Guardian

TM

Leak Detector System is

optional on Greensmaster TriFlex Hybrid machines.

The leak detector oil level sensor closely monitors the

hydraulic fluid level in the main hydraulic reservoir. The

sensor is open when the sensor float is in the raised

positionand closedwhen thefloat isin theloweredposi-

tion. See Turf Guardian

TM

Leak Detector System Op-

eration in this chapter for information regarding Leak

Detector System operation.

Oil Level Sensor Testing

NOTE: On Greensmaster 3320 machines, the leak de-

tector oil level sensor is an input for the TEC controller.

Before disconnecting the oil level sensor for testing on

a Greensmaster 3320, the sensor and its circuit wiring

should be tested as a TEC electrical input using Hand

HeldDiagnostic Display (see Hand HeldDiagnosticDis-

play in the Troubleshooting section of this chapter) or

InfoCenter Display (see InfoCenter Display in this

chapter). If input testing verifies that the oil level sensor

and circuit wiring are functioning correctly, no further

sensor testing is necessary. If, however, input testing

determines that th eoil levelsensor andcircuit wiringare

not functioning correctly, proceed with the following

sensor testing procedure.

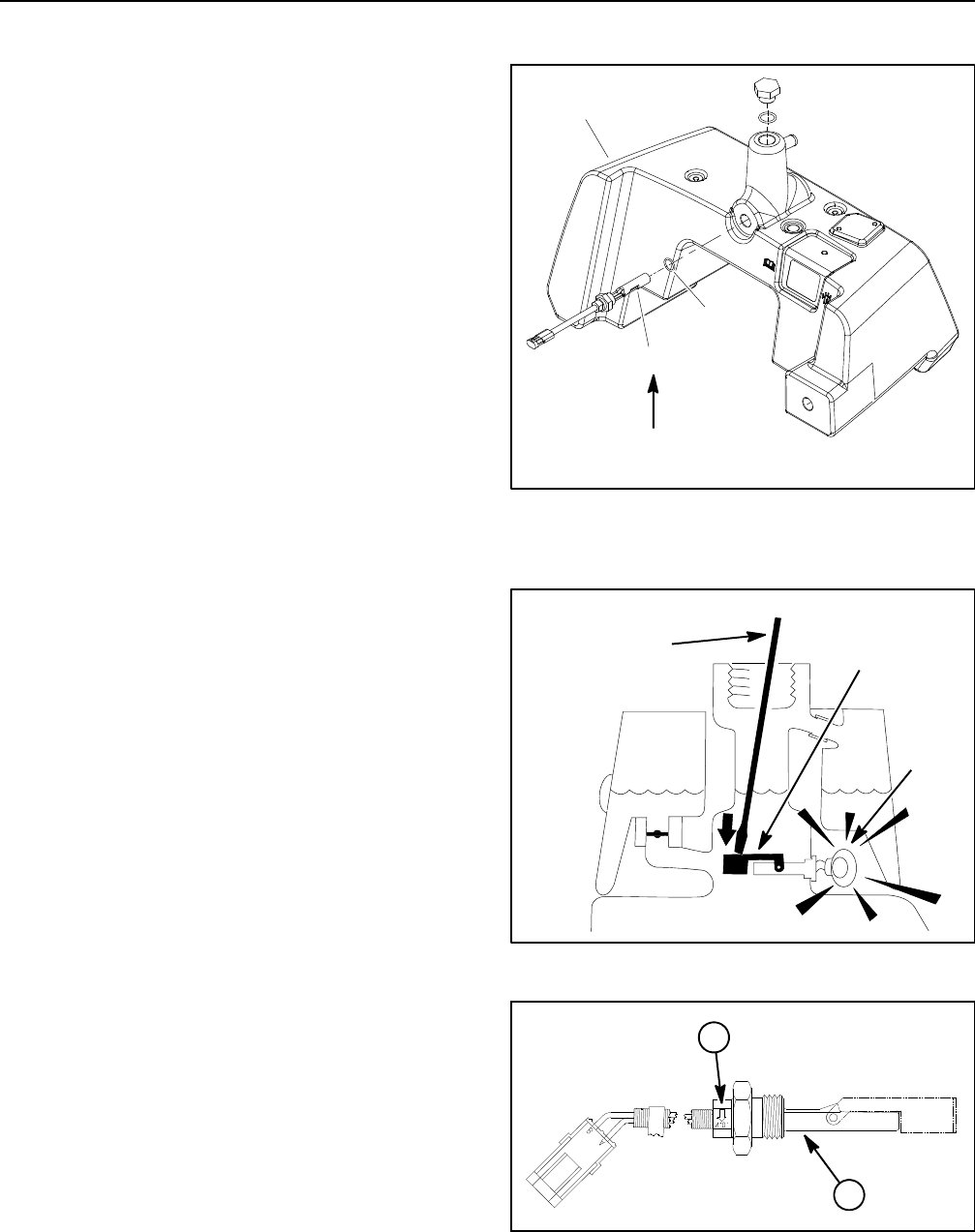

1. If the oil level sensor is connected to the main wire

harness, remove hydraulic tank cap from filler neck of

hydraulic reservoir. Start the engine. Insert a clean rod

or screw driver into filler neck and gently p ush down on

sensor float (Fig. 95). Alarm should sound and console

leak detector indicator light should illuminate after a one

(1) second time delay.

2. If the oil level sensor is removed or disconnected

from the main wire harness, connect a continuity tester

acrossthe sensor wireterminals. There should beconti-

nuity (low resistance) across the sensor connector ter-

minals when the float is pushed down. There should not

be continuity (infiniteresistance) across the sensorcon-

nector terminals when the float is in the raised position.

3. If oil level sensor was removed from reservoir, install

oil level sensor into reservoir making sure that arrow on

sensor is pointing down (Fig. 96). Torque sensor nut

from 110to140in-lb(12.5to15.8N-m).

4. Aftertesting, makesure that hydraulicoil level inres-

ervoir is correct.

1. Hydraulic reservoir

2. Oil level sensor

3. O-ring

Figure 94

2

1

3

110 to 140 in- lb

(12.5to15.8N-m)

Figure 95

ALARM

(on)

FLOAT SWITCH

(lowered/closed)

CLEAN ROD OR

SCREWDRIVER

1. Oil level sensor 2. Sensor arrow

Figure 96

1

2