Groundsmaster 4000--DHydraulic System (Rev. B) Page 4 -- 54

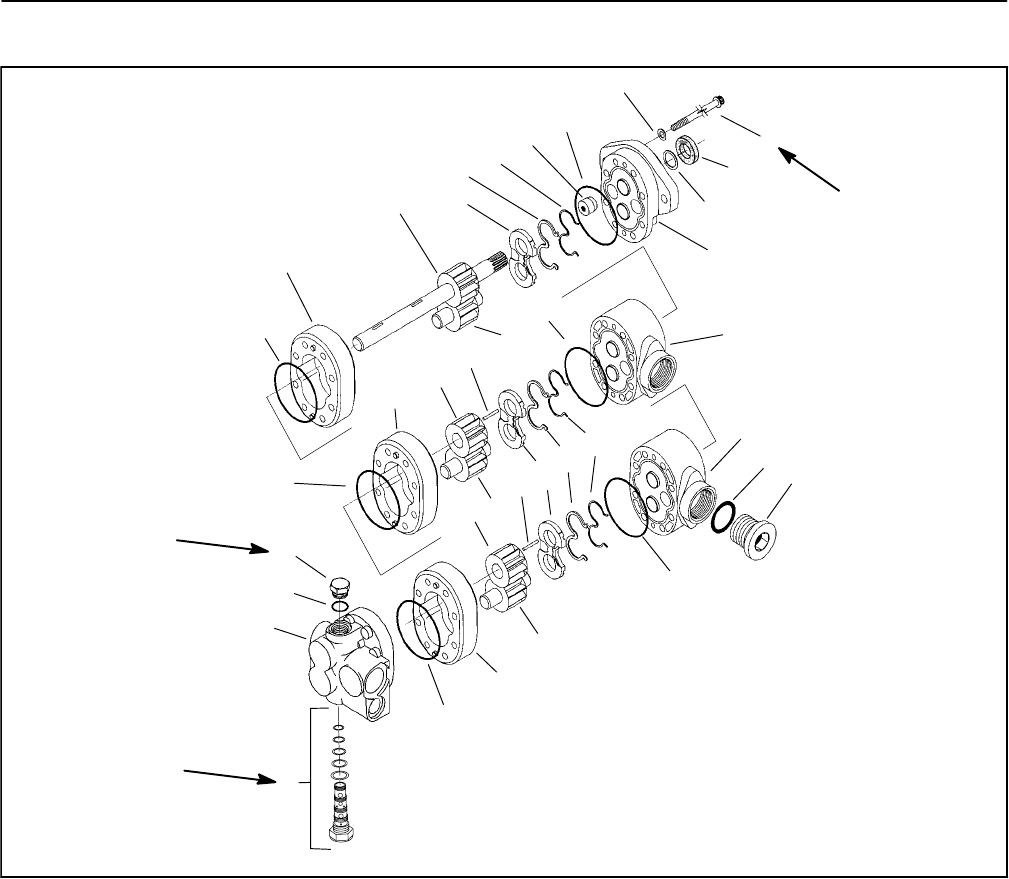

Gear Pump Service

1. Shaft seal

2. Washer

3. Cap screw

4. O--ring

5. Washer

6. Proportional valve

7. Plug

8. Plug

9. O--ring

10. Front body

11. Drive gear assembly

12. Wear plate

13. Pressure seal

14. Backup gasket

15. Front plate assembly

16. Idler gear

17. Key

18. Gear

19. Middle body

20. Gear

21. Idler gear

22. Key

23. Front adapter plate

24. Rear adapter plate

25. Idler gear

26. Rear body

27. Backplate assembly

28. Plug

29. O--ring

Figure 40

4

10

11

12

13

14

8

15

5

3

19

20

21

22

23

24

9

7

25

26

6

1

2

16

17

18

27

4

4

4

4

4

14

13

12

28

29

25 to 28 ft--lb

(34to38N--m)

21 to 24 ft--lb

(29to33N--m)

21 to 24 ft--lb

(29to33N--m)

Disassembly

Work in a clean area as cleanliness is extremely impor-

tant when repairing hydraulic pumps. Thoroughly clean

the outside of pump. After cleaning, remove port plugs

and drain oil from pump.

1. Scribe a line, at an angle, across front plate (15), bo-

dies (10, 19, 26), adapter plates (23, 24) and backplate

(27). This will assure proper reassembly.

NOTE: To maintain maximum pump efficiency, keep

body, gears and wear plates for each s ection together.

DO NOT mix parts between different sections.

IMPORTANT: Avoid using excessive clamping

pressure on the pump housing to prevent distorting

the housing.

2. Clamp pump in vise, shaft end up and remove the

eight cap screws (3).