Groundsmaster 4000--D Hydraulic System (Rev. B)Page 4 -- 81

Removal

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

NOTE: To ease reassembly, tag the hydraulic hoses to

show their correct position on the wheel motor.

3. Disconnect hydraulic hoses and tubes from wheel

motor. Put caps or plugs on ports to prevent contamina-

tion.

IMPORTANT: Before loosening f asteners, support

wheel motor to prevent motor from falling during re-

moval.

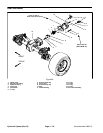

4. Remove wheel motor using Figure 61 as a guide.

Installation

1. Positionwheel motor to brake assembly making sure

that arrows on the side of motor case point upward.

2. Align splines on motor shaft and splined brake shaft.

Slide motor into brake assembly.

3. Secure motor to brake assembly with cap screws

and flat washers. Tighten cap screws from 75 to 85 ft--lb

(101 to 115 N--m).

4. Remove plugs from ports. Attach hydraulic hoses

and tubes to wheel motor.

5. Fill reservoir with hydraulic fluid as required (seeOp-

erator’s Manual).

Hydraulic

System