Groundsmaster 4000--D Hydraulic System (Rev. B)Page 4 -- 27

Procedure for Traction Circuit Relief Pressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

Move machine to an open a rea, away from people

and obstructions.

CAUTION

2. Drive machine to an open area, lower cutting units,

turn the engine off and engage the parking brake.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS, and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3. Connect a 10,000 psi gauge to traction circuit test

port for function to be checked (Fig. 16).

4. Start the engine and movethrottle to full speed (2730

+

30 RPM). Release parking brake.

5. Siton seat, apply brakes fully, andslowly depress the

traction pedal in the appropriate direction. While pu-

shing traction pedal, look at pressure reading on gauge:

GAUGE READING TO BE:

Forward: 4000 PSI

Reverse: 5000 PSI

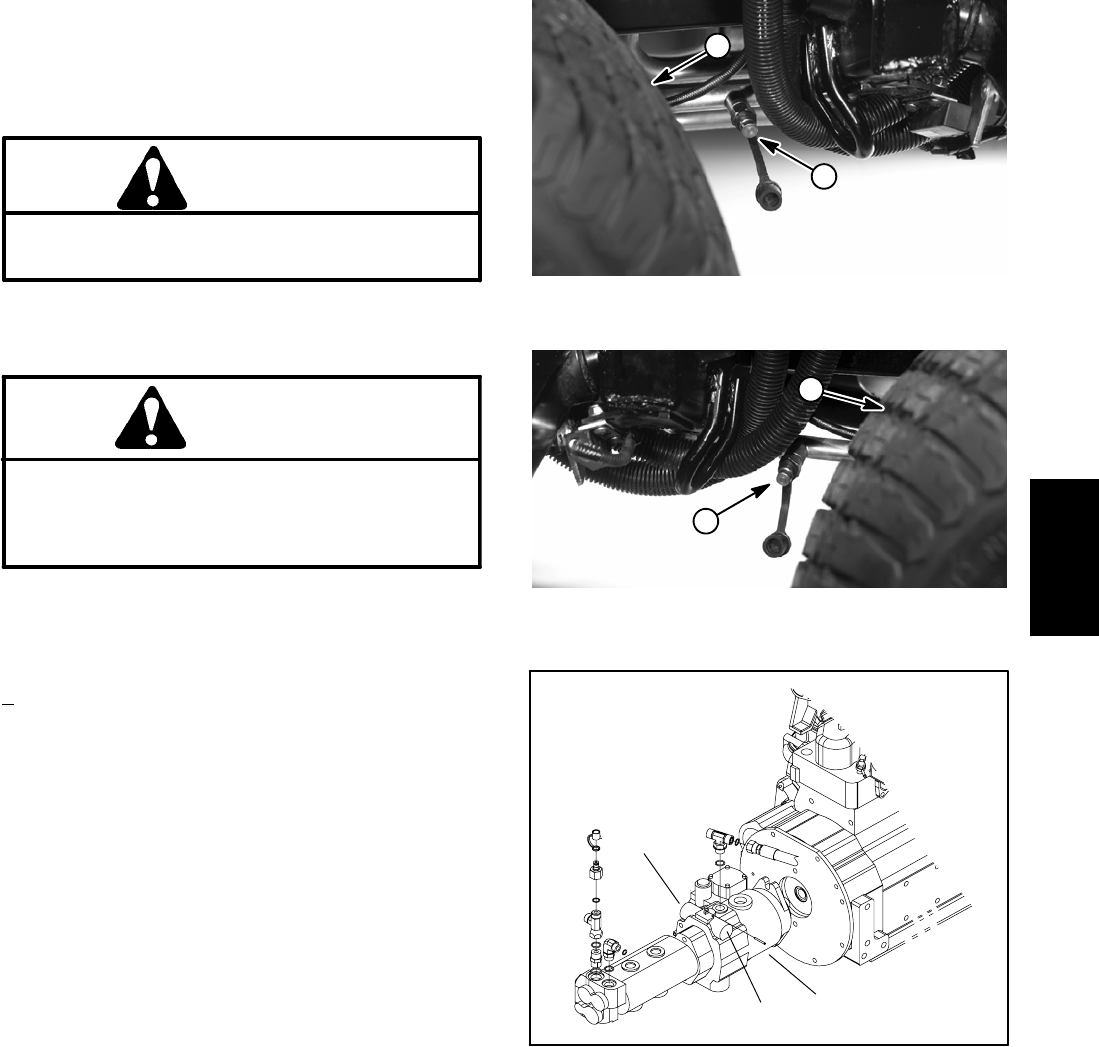

6. If traction pressure is too low, inspect traction pump

relief valves (Fig. 17). Clean orreplace valves as neces-

sary. These cartridge type valves are factory set, and

are not adjustable. If relief valves are in good condition,

traction pump or w heel motors should be suspected of

wear and inefficiency.

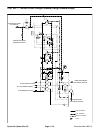

1. Forward traction port 2. Left front wheel

Figure 15

1

2

1. Reverse traction port 2. Right front wheel

Figure 16

1

2

1. Forward relief valve

2. Reverse relief valve

3. Traction pump

Figure 17

1

2

3

Hydraulic

System