Rev. E

Groundsmaster 4000--DHydraulic System (Rev. B) Page 4 -- 68

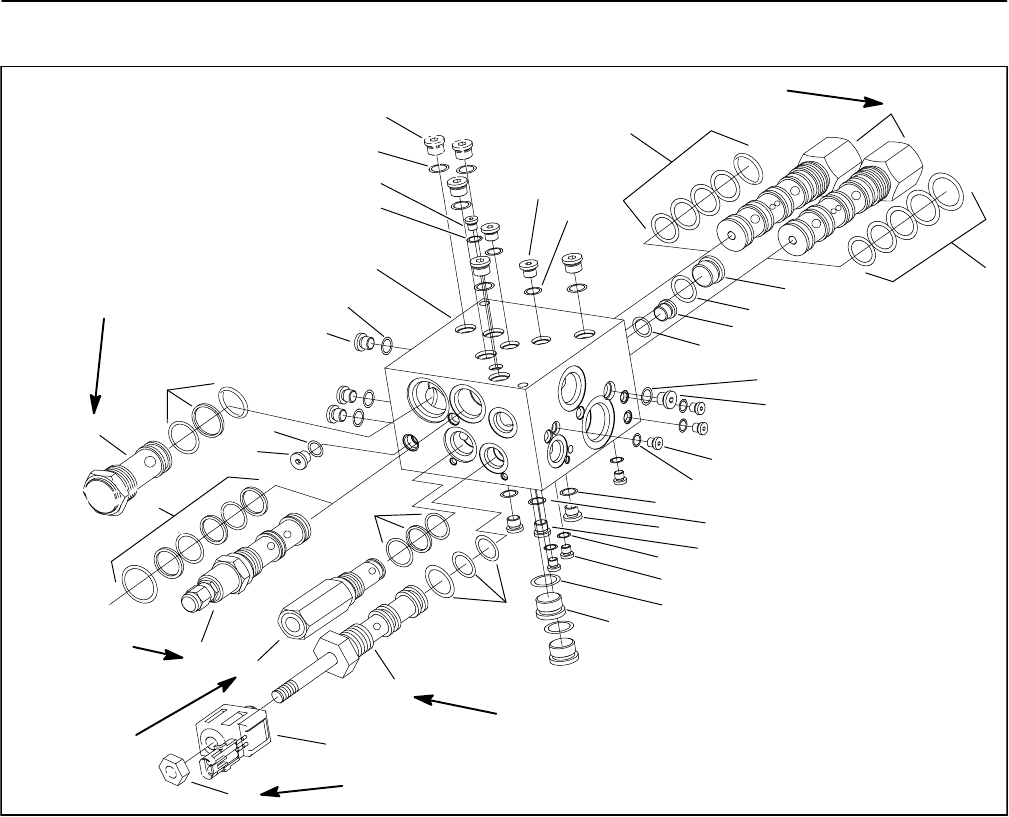

Hydraulic Control Manifold Service: 4 Wheel Drive

1. Manifold body

2. Solenoid valve (port 2)

3. Seal kit

4. Check valve (port 3)

5. Seal kit

6. Control valve (ports 5A & 5B)

7. Seal kit

8. Relief valve (port 7)

9. Seal kit

10. Reducing valve (port 8)

11. Seal kit

12. Plug (SAE #2)

13. O--ring

14. Plug (SAE #4)

15. O--ring

16. Plug (SAE #5)

17. O--ring

18. Plug (SAE #6)

19. O--ring

20. Plug (SAE #10)

21. O--ring

22. Solenoid coil

23. Nut

Figure 50

6

7

20

21

18

19

16

17

19

18

16

17

12

13

20

21

12

13

16

17

14

15

12

13

16

17

16

17

10

8

22

2

3

1

23

4

5

11

9

7

35 to 40 ft--lb

(47to54N--m)

25 to 30 ft--lb

(34to41N--m)

80 to 90 ft--lb

(108 to 122 N--m)

60 to 70 ft--lb

(81to95N--m)

4to6ft--lb

(5 to 8 N--m)

80 to 90 ft--lb

(108 to 122 N--m)

EATON/VICKERS MANIFOLD

NOTE: The ports on the manifold are marked for easy

identification of components. Example: P1 is a piston

pump connection port and 2 is the location for the sole-

noid valve (See Hydraulic Schematics to identify the

function of the hydraulic lines and cartridge valves at

each port).

NOTE: 4WD manifolds used on Groundsmaster

4000--D machines are either Eaton/Vickers (Fig. 50) or

JEM (Fig. 51).

Valve Cartridge Service

1. Make sure the manifold is clean before removing the

valve.

2. If cartridge is solenoid operated, remove nut secur-

ing solenoid to the cartridge valve. Carefully slide sole-

noid off the valve.

IMPORTANT: Use care when handling the valve car-

tridge. Slight bending or distortion of the stem tube

can cause binding and malfunction.

3. Remove cartridge valve with a deep socket wrench.

Note correct location for o--rings, s ealing rings, and

backup rings. Remove and discard seal kit.

4. Visually inspect the port in the manifold for damage

to the sealing surfaces, damaged threads, and contami-

nation.