Groundsmaster 4000−D Page 6 − 5 Axles, Planetaries, and Brakes (Rev. B)

CAUTION

When changing attachments, tires, or perform-

ing other service, use correct blocks, hoists,

and jacks. Make sure machine is parked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attach-

ments that may interfere with the safe and

proper raising of the machine. Always chock or

block wheels. Use jack stands or solid wood

blocks to support the raised machine. If the ma-

chine is not properly supported by blocks or

jack stands, the machine may move or fall,

which may result in personal injury.

3. Chock rear wheels and jack up front of machine (see

Jacking Instructions in Chapter 1 − Safety). Support ma-

chine with jack stands or solid wood blocks.

4. Remove wheel assembly.

5. Remove hydraulic wheel motor (see Front Wheel

Motors in Service and Repairs section of Chapter 4 −

Hydraulic System).

6. Disconnect brake cable from pull rod on brake.

7. Remove flange head capscrews (5) securing brake

assembly to frame; be careful not to drop splined brake

shaft as brake assembly is removed.

8. Remove splined brake shaft.

9. Complete brake inspection and repair.

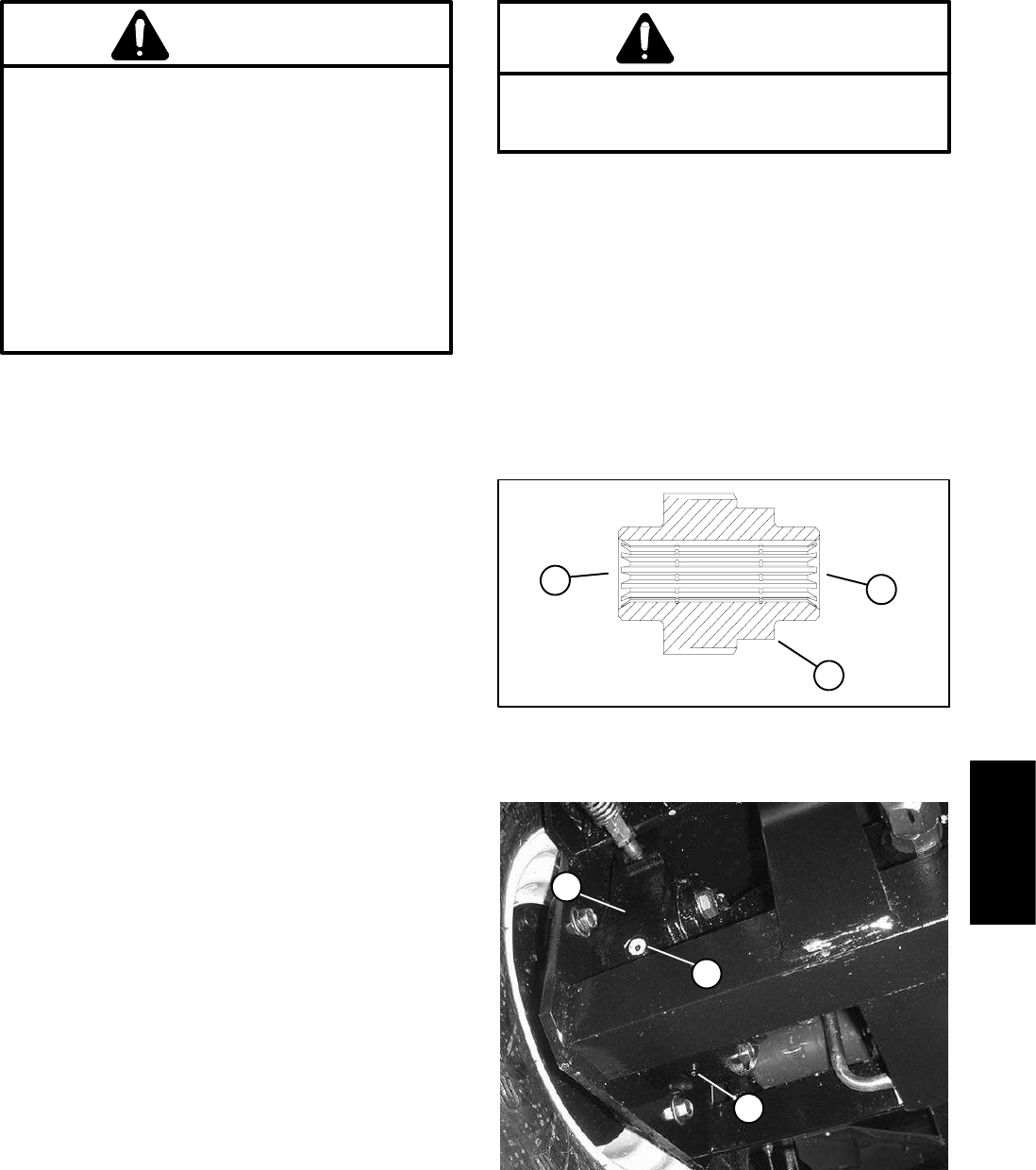

Install Brake Assembly (Fig. 1)

1. Install splined brake shaft into brake assembly.

Note: The stepped end of the splined brake shaft must

be aligned toward the hydraulic wheel motor (Fig. 2).

2. Install brake assembly onto frame, aligning splined

brake shaft with input shaft on planetary wheel drive.

3. Install flange head screws (5) to secure brake as-

sembly to frame. Tighten screws in a crossing pattern to

a torque from 75 to 85 ft−lb (101 to 115 N−m).

4. Install brake cable to pull rod on brake assembly.

Brake cable end should be completely threaded onto

pull rod.

5. Install new o−ring on hydraulic wheel motor. Install

wheel motor and torque capscrews from 75 to 85 ft−lb

(101 to 115 N−m).

WARNING

Failure to maintain proper torque could result

in failure or loss of wheel and may result in

personal injury.

6. Install wheel assembly. Torque lug nuts from 85 to

100 ft−lb (115 to 135 N−m).

7. Lower machine to ground.

8. Make sure drain plug is installed in bottom of brake

assembly (Fig. 3). Fill planetary wheel drive/brake as-

sembly with SAE 85W−140 gear lube (see Operator’s

Manual). Capacity is approximately 16 oz. (.47 l) per

wheel.

9. Check and adjust brake cables for proper brake op-

eration (see Operator’s Manual).

1. Splined brake shaft step

2. Hydraulic motor end

3. Planetary assembly en

d

Figure 2

3

1

2

1. Brake housing

2. Check plug

3. Drain plug

Figure 3

1

2

3

Axles, Planetaries,

and Brakes