Groundsmaster 4100--D Hydraulic SystemPage 4 -- 53

Procedure for Lift/Lower Circuit Relief Pressure

Test

NOTE: Before attempting to check or adjust lift pres-

sure, make sure that counterbalance pressure is cor-

rectly adjusted.

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2. Parkmachineon a level surface with thecuttingdeck

lowered and off. Make sure engine is off and the parking

brake is engaged.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3. Raise s eat to gain access to hydraulic test fitting.

Connect a 5,000 PSI (345 bar) gauge to lift circuit test

port(Fig.41). Route gauge hosetoallow seat tobesafe-

ly lowered.

4. After installing pressure gauge, start engine and run

at idle speed. Check for hydraulic leakage and correct

before proceeding with test.

5. Sit on the seat and operate the engine at full speed

(2870 RPM).

6. While sitting on the seat, pull lift lever back to raise

the cutting deck. Momentarily hold the lever with the lift

cylinder fully retracted (deck fully raised) while looking

at the gauge.

GAUGE READING TOBE2500to2550PSI(173 to

175 bar).

7. Stop the engine and record test results.

8. If pressure is too high, adjustrelief valve in lift control

valve by rotating counterclockwise (Figure 42). If pres-

sure is too low, check for restriction in pump intake line.

Check the lift cylinder for internal leakage. If cylinder is

not leaking, adjust the relief valve by rotating clockwise.

If pressure is still too low, pump or lift cylinder(s) should

be suspected of wear, damage or inefficiency.

9. When testing is completed, disconnect pressure

gauge from test port.

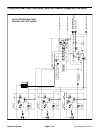

1. Fan drive manifold

2. Lift circuit test port

3. Lift control valve

4. Relief valve

Figure 41

1

2

3

4

1. Control valve assembly

2. Relief valve assembly

3. Washers

4. Spring

5. Poppet

Figure 42

2

3

1

4

5

Hydraulic

System