Groundsmaster 4100--DHydraulic System Page 4 -- 20

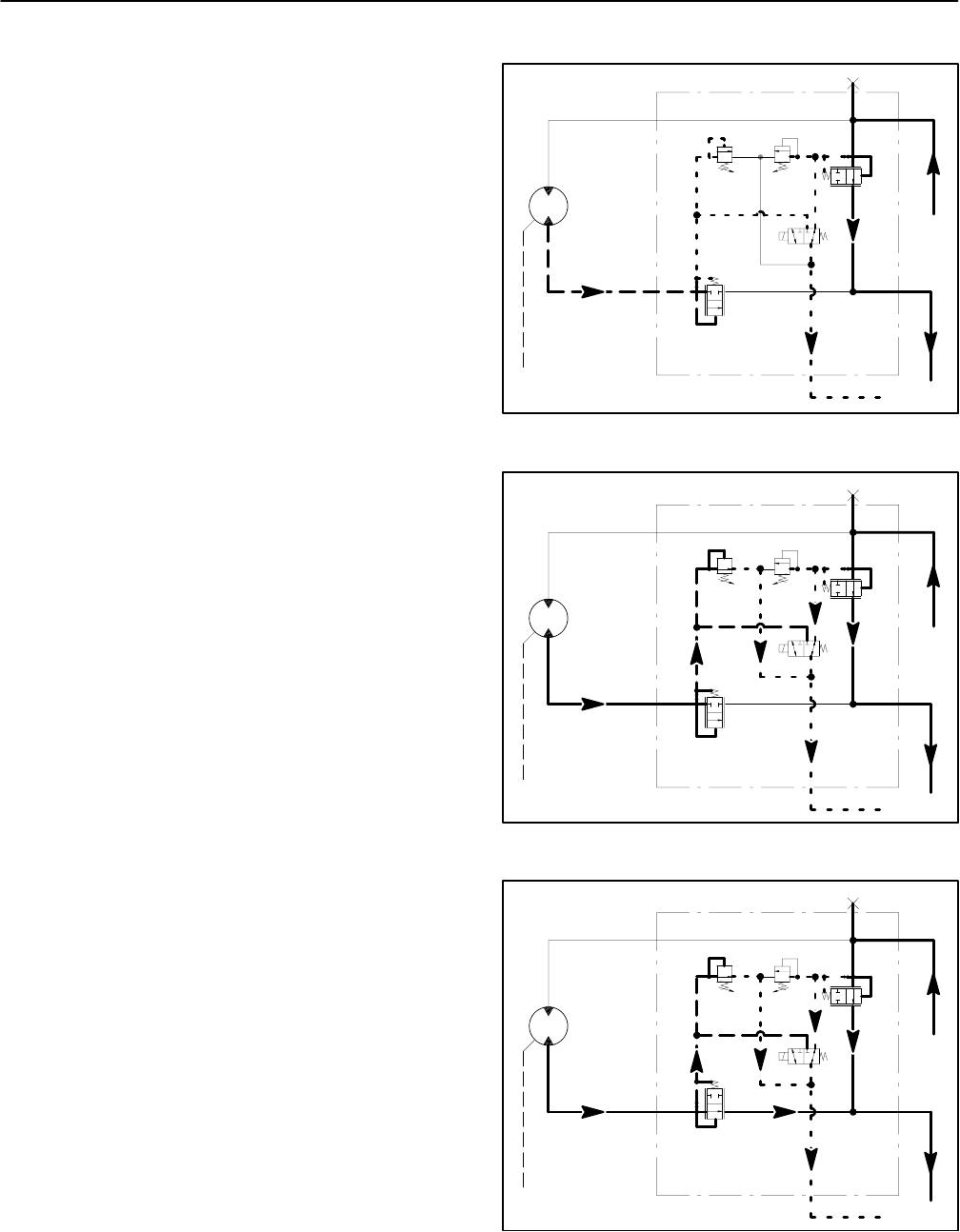

Mow Circuit Cutting Deck Blade Braking

When theoperatorturns the PTOswitch OFF or if adeck

is raised with the PTO switch ON, deck control manifold

solenoid valve (S) is de--energized causing logic car-

tridge (LC1)toshift (refer toinformationin PTO MowCir-

cuit in this section). This shifted cartridge allows oil

return out manifold port P2. At the same time, solenoid

valve (S) in its neutral position prevents any sense line

flow through the s pool which causes the logic cartridge

LC2 to shift to its neutral position blocking return flow

from the deckmotor and slowing thecutting blades (Fig.

10).

The inertia oftherotatingcutting blades, however, effec-

tively turns the deck motor into a pump causing an in-

crease in pressure as the flow from the motor comes up

againsttheclosed logic cartridge (LC2).Whenthis pres-

sure builds to approximately 600 PSI (41 bar), relief

valve (RV2) opens which allows a small amount of hy-

draulic flow to return to tank through a manifold sensing

line (Fig. 11). This flow causes a pressure increase that

shifts logic cartridge LC2 to once again allow oil flow

from the motor (Fig. 12). When motor return pressure

drops below 600 PSI (41 bar), relief valve (RV2) reseats

and causes LC2 to close again blockingreturn flow from

the deck motor to further slow the cutting blades. This

action of thebrakereliefvalveopeningandthelogiccar-

tridge shifting occurs several times in a very s hort time

frame as the blades finally come to a stop. Once the

blades have stopped, logic cartridge LC2 remains in the

neutral position to k eep the deck motor from rotating.

Figure 10

MOTOR

CD

DECK

G

RV1

RV2

LC2

LC1

S

P1

P2

M1

M2

DECK MANIFOLD

Figure 11

MOTOR

CD

DECK

G

RV1

RV2

LC2

LC1

S

P1

P2

M1

M2

DECK MANIFOLD

Figure 12

DECK MANIFOLD

MOTOR

CD

DECK

G

RV1

RV2

LC2

LC1

S

P1

P2

M1

M2