Groundsmaster 4100--D Page 7 -- 7 Chassis

Removal (Fig. 5)

1. Park machine on a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Remove seat from seat suspension:

A. Disconnect seat electrical connectors from ma-

chine wire harness (Fig. 6).

B. Remove four (4) Torx head screws that secure

seat to seat suspension (Fig. 7). Note that the screw

near the seat adjustment handle is longer than the

other three (3) screws.

C. Lift seat from seat suspension and remove from

machine.

NOTE: Most of the seat suspension components can

be serviced with the seat suspension base mounted to

the frame platform.

3. Ifnecessary,remove seat suspensionfrom seatplat-

form:

A. Tilt seat to gain access to mounting fasteners.

Support seat suspension to prevent it from falling.

B. Remove four (4) cap screws and flange nuts that

secure seat suspension to seat plate. Note that two

(2) r--clamps that retain wire harness are secured

with seat suspension fasteners.

C. Lift seat suspension from machine.

Installation (Fig. 5)

1. If removed, install seat suspension to seat platform:

A. Position seat suspension onto seat plate.

B. Secureseat suspension and two(2)wire harness

r--clamps to seat platform with four (4) cap screws

and flange nuts.

C. Lower seat plate and suspension.

2. Install seat to seat suspension:

A. Carefully position seat to seat suspension.

B. Secure seat to seat suspension with four (4) Torx

head screws (Fig. 7). Make sure that longer screw is

positioned near the seat adjustment handle.

C. Torque screws 18 ft--lb (25 N--m).

3. Connect seat electrical connectors to machine wire

harness (Fig. 6).

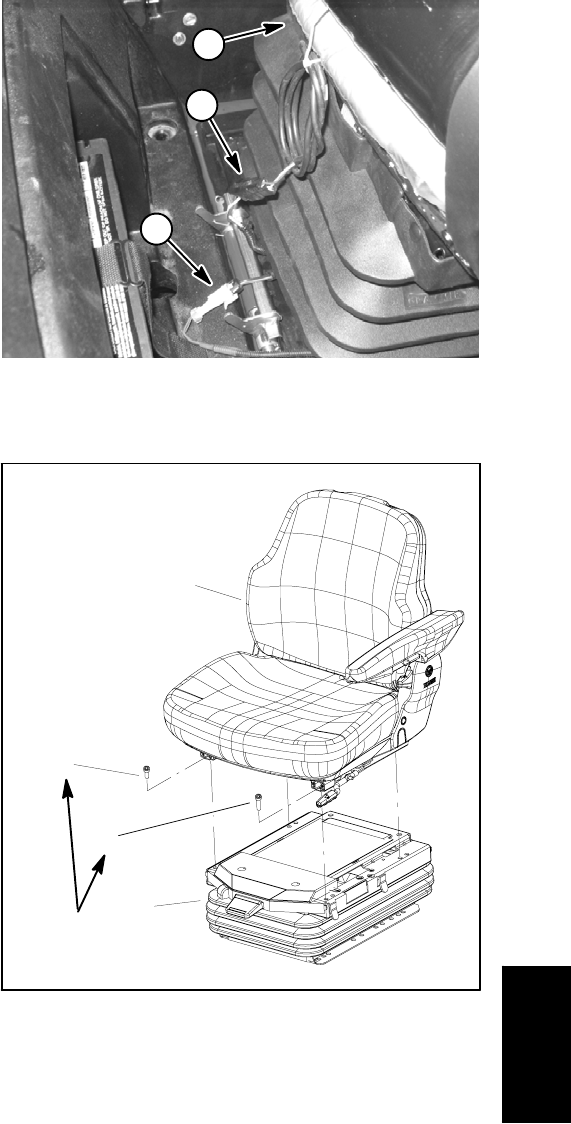

1. Operator seat

2. Seat switch connector

3. Suspension connector

Figure 6

1

2

3

1. Seat

2. Suspension assembly

3. Screw (M8x12) (3 used)

4. Screw (M8x16)

Figure 7

2

3

1

4

18 ft--lb

(25 N--m)

Chassis