Groundsmaster 4100--D Hydraulic SystemPage 4 -- 45

Procedure for Cutting Deck Manifold Relief

Pressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2. Parkmachineon a level surface with thecuttingdeck

lowered and off. Make sure engine is off and the parking

brake is engaged.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

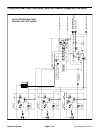

3. Locate deck manifold to be tested (Fig. 34). Discon-

nect hydraulic hose at deck manifold port (M1).

NOTE: Analternative to using manifold port (M1)would

be to disconnect the inlet hydraulic hose at deck motor.

4. Install tester with pressure gauges and flow meter in

series with the the disconnected hose and hydraulic

manifold port (M1) (or motor inlet if hose was discon-

nected at deck motor).

5. Make sure the flow control valve on tester is fully

open.

6. After installing tester, start engine and run at idle

speed. Check for hydraulic leakage and correct before

proceeding with test.

CAUTION

Keep away from deck during test to prevent per-

sonal injury from the cutting blades.

7. Operate engine at full speed (2870 RPM). Engage

the cutting deck.

8. Watch pressure gauge carefully while slowly closing

the flow control valve to fully closed.

9. As the relief valve lifts, system pressure should be

approximately:

2900 to 3100 PSI (200 to 213 bar) for the center

deck and LH wing deck

1900 to 2100 PSI (131 to 144 bar) for the RH wing

deck

10.Disengage cutting deck. Shut off engine and record

test results.

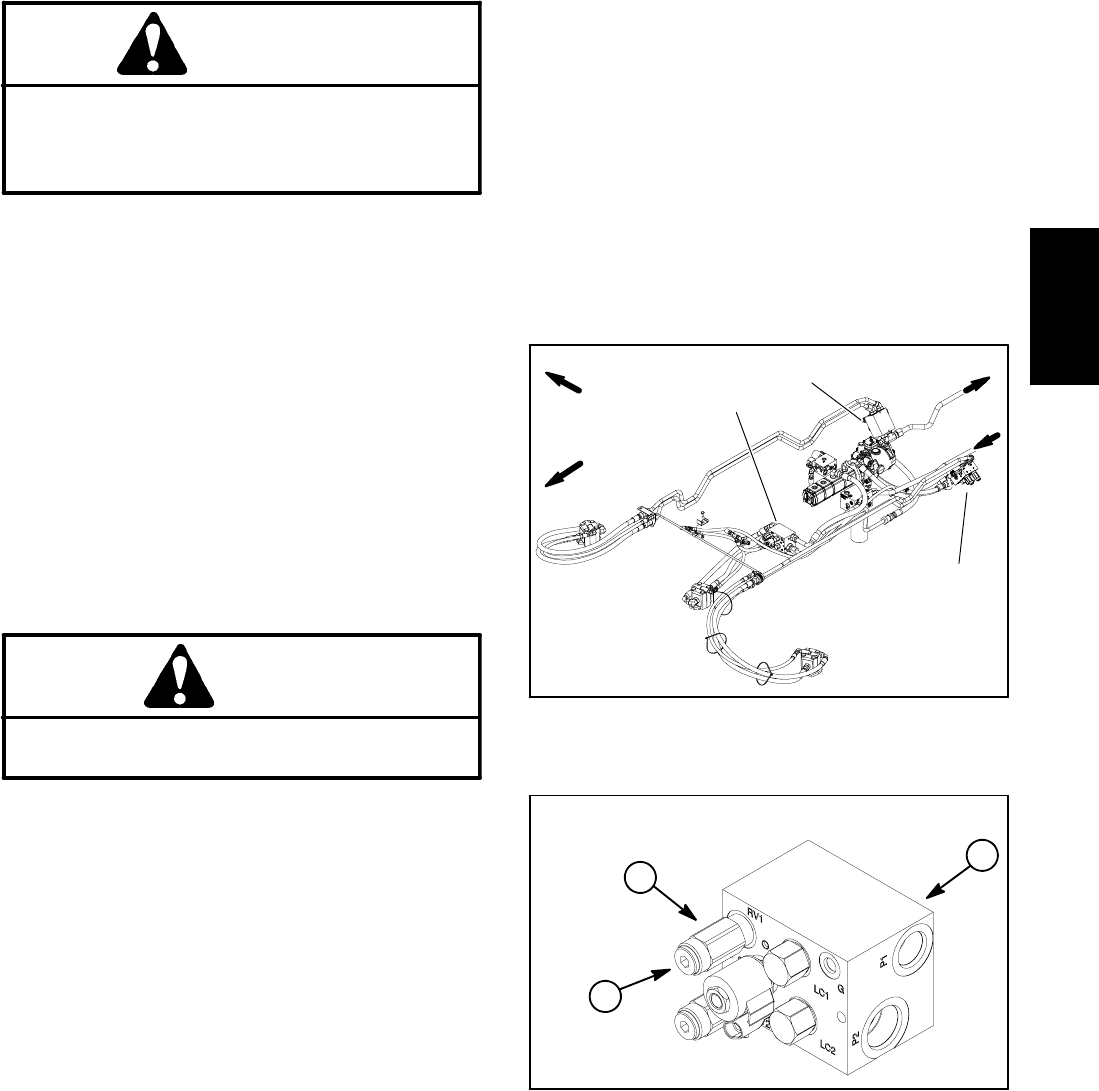

11.If specification is not met, adjust or clean relief valve

in deck manifold port (RV1). Adjust relief valve as fol-

lows:

NOTE: Do not remove valve from the hydraulic

manifold for adjustment.

A. Remove cap on relief valve with an allen wrench.

B. To increase pressure setting, turn the adjust-

ment screw on the valve in a clockwise direction. A

1/8turnon thescrewwill makeameasurable change

in relief pressure.

C. To decrease pressure setting, turn the adjust-

ment screw on the valve in a counterclockwisedirec-

tion. A 1/8 turn on the screw will make a measurable

change in relief pressure.

D. Install and tighten cap to secure adjustment. Re-

check relief pressure and readjust as needed.

12.Disconnect tester from manifold and hose. Recon-

nect hydraulic hose that was disconnected for test pro-

cedure.

1. Center deck manifold

2. LH wing deck manifold

3. RH wing deck manifold

Figure 34

FRONT

RIGHT

TO OIL COOLER

1

2

3

1. Deck manifold

2. Relief valve

3. Relief valve cap

Figure 35

1

2

3

FRONT DECK MANIFOLD SHOWN

Hydraulic

System