Groundsmaster 4100--D Cutting DeckPage 8 -- 13

Cutting Deck Link Service

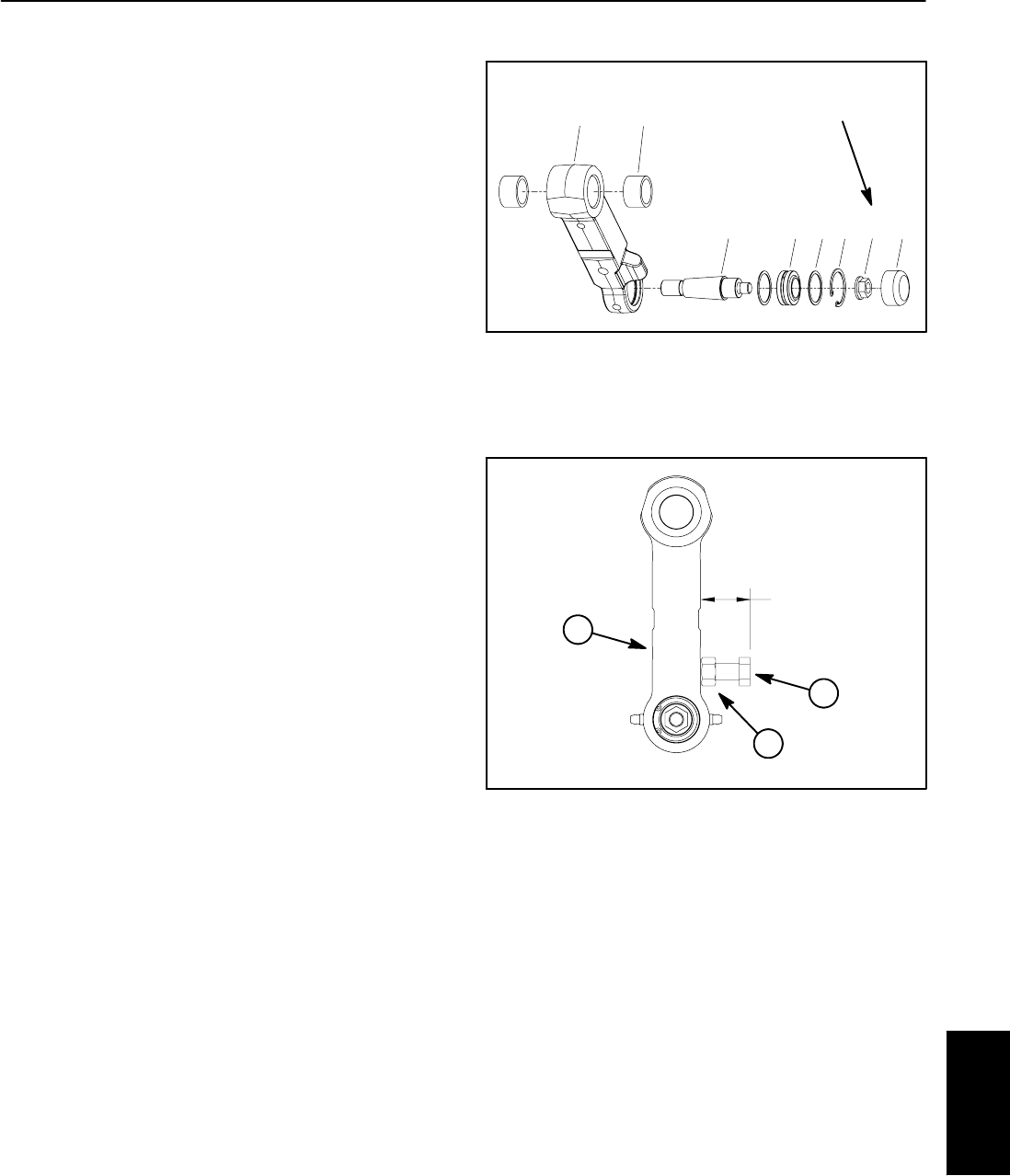

Disassembly (Fig. 10)

1. Press bushings from top of link.

2. Remove dust cap and retaining ring from link.

3. Press tapered stud with spherical bearing, flat wash-

ers and flange nut from link.

4. Remove flange nut and press spherical bearing from

tapered stud.

Assembly (Fig. 10)

1. Install new spherical bearing onto tapered stud. Se-

cure bearing with flange nut. Torque nut from 30 to 40

ft--lb (41 to 54 N--m).

2. Position flat washer in both sides of spherical bear-

ing.

3. Press tapered stud with spherical bearing, flat wash-

ers and flange nut into link. Secure spherical bearing

into link with retaining ring.

4. Press bushings into top bore of link.

5. If cap screw and jam nut were removed from rear

link,installcap screw toallow 1.625” (41.3 mm)between

the head of the screw and the side of the link (Fig. 11).

6. After link is installed on deck, check distance be-

tween center deck blade and wing deck blade. Readjust

cap screw and jam nut on rear link if needed (see Wing

Deck Service in this Chapter).

1. Link

2. Bushing (2 used)

3. Tapered stud

4. Spherical bearing

5. Flat washer (2 used)

6. Retaining ring

7. Flange nut

8. Dust cap

Figure 10

30 to 40 ft--lb

(41to54N--m)

1

3

6

7

4

5

2

8

1. Rear link

2. Cap screw

3. Hex jam nut

Figure 11

1.625”

(41.3 mm)

1

2

3

Cutting Deck