Groundsmaster 4100--D Page 5 -- 25 Electrical System

Fuel Gauge

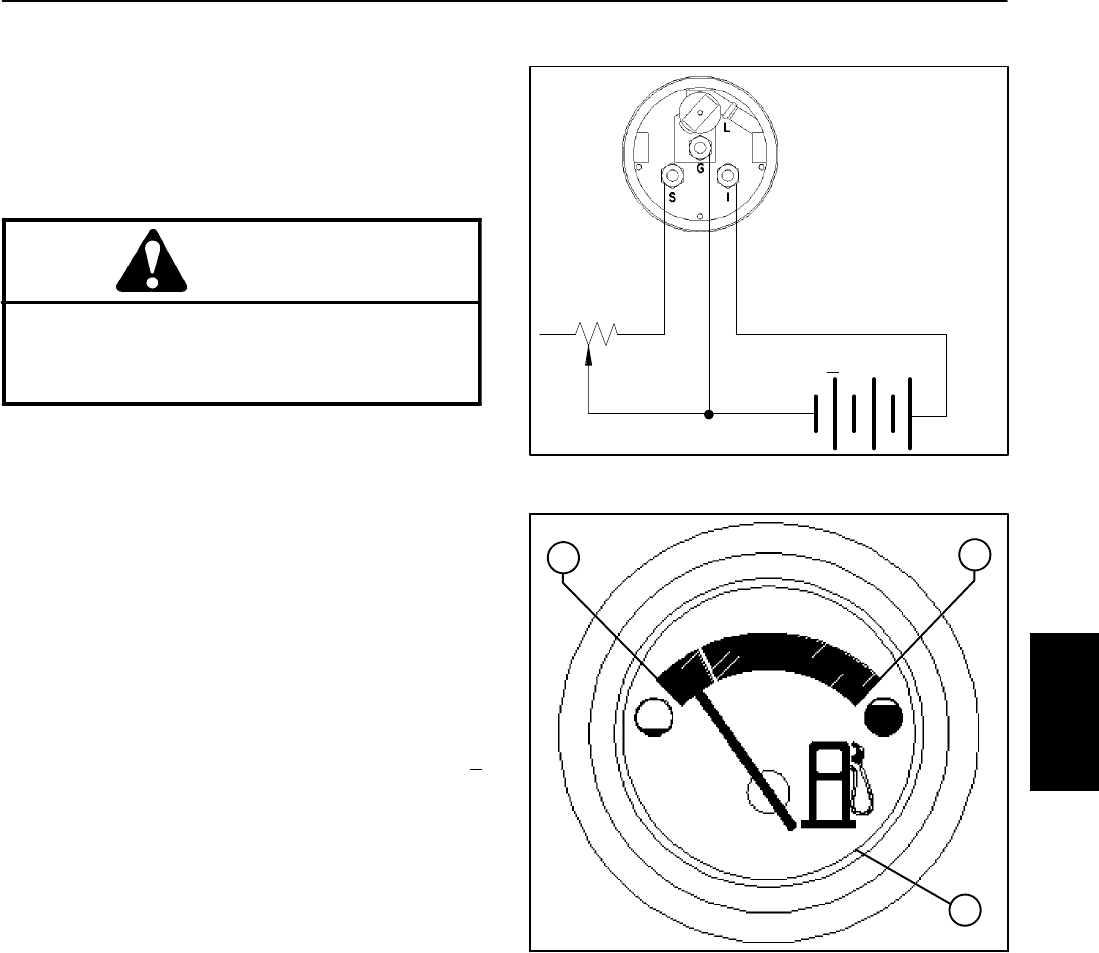

The fuel gauge can be tested using a new gauge as a

substitute or with the use of a DC voltage source and a

variable resistance box (see Fuel Sender Testing in this

section for additional information).

Testing

CAUTION

Make sure the voltage source is turned OFF be-

fore connecting it tothe electrical circuit to avoid

electrical shock and prevent damaging the

gauge.

1. Connect fuel gauge to the variable resistance and

DC voltage source (Fig. 36).

NOTE: When reading the gauge test point, there are

two white dots on the gauge face below the edge of the

glass cover for each test point. For each variable resist-

ance setting, the needle must be pointed between the

two white dots.

2. Take test point readings (Fig. 37).

IMPORTANT: Allow circuit to warm up for at least 5

minutes before taking test readings.

A. Setvariable resistance to 240 ohms. Apply a 14 +

0.01 VDC to the circuit. The needle should point to

the left edge of the red area (empty).

B. Set variable resistance to 33 ohms. The needle

should point to the right edge of the green area (full).

3. Turn off the voltage source. Disconnect voltage

source, gauge and variable resistance.

Figure 36

+

--

VARIABLE

RESISTANCE

14 VDC + 0.01 VDC

1. Empty position

2. Full position

3. Glass face edge

Figure 37

1

2

3

Electrical

System