Groundsmaster 4100--D Hydraulic SystemPage 4 -- 51

Procedure for Steering Circuit Relief Pressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2. Parkmachineon a level surface with thecuttingdeck

lowered and off. Make sure engine is off and the parking

brake is engaged.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

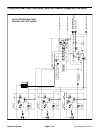

3. Connect a 5000 PSI (350 bar) gauge onto steering

circuit pressure test port (Fig. 39).

4. After installing pressure gauge, start engine and run

at idle speed. Check for hydraulic leakage and correct

before proceeding with test.

5. Operatetheengine at full engine speed(2870RPM).

IMPORTANT: Hold steering wheel at full lock only

long enough to get a system pressure reading.

Holding the steering wheel against the stop for an

extended period will damage the steering motor.

6. Turn steering all the way in one direction and mo-

mentarily hold the steering wheel against resistance.

GAUGE READING TO BE 1300 to 1400 PSI (90 to

96 bar).

7. Stop the engine and record test results.

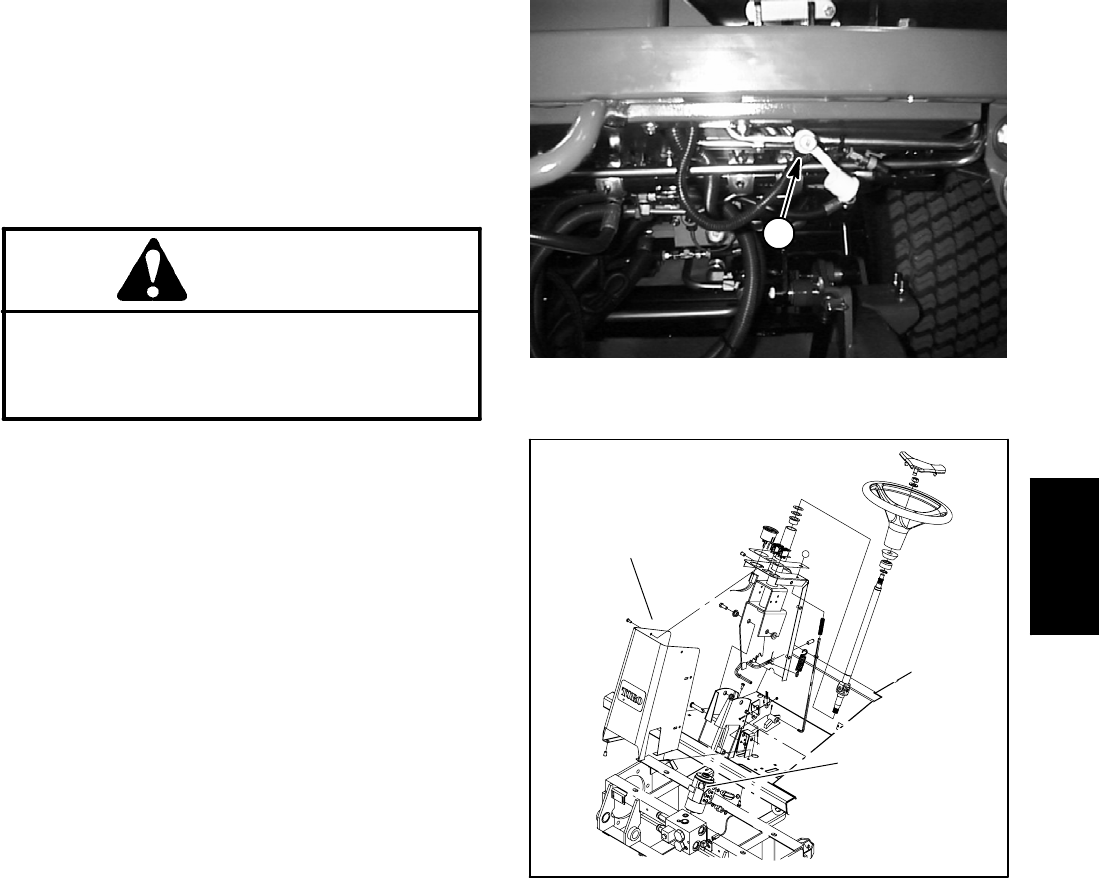

8. If pressure is incorrect, inspect steering relief v alve

in controlvalve(Fig.40). If steering reliefvalveisoperat-

ing properly and if lift/lower problems also exist, gear

pump should be suspected of wear and inefficiency. If

steering wheel continues to turn at end of cylinder travel

(with lower than normal effort), steering cylinder or

steering valve should be suspected of wear or damage.

9. When testing is completed, disconnect pressure

gauge from test port.

1. Steering circuit pressure test port

Figure 39

1

1. Steering tower 2. Steering relief valve

Figure 40

2

1

Hydraulic

System