Groundsmaster 4100--D Page 6 -- 17 Axles, Planetaries and Brakes

Bevel Gear Case and Axle Case

The following procedures assume the rear axle assem-

bly has been removed from the machine (see Rear Axle

Assembly Removal in this section).

Bevel Gear Case and Axle Case Removal

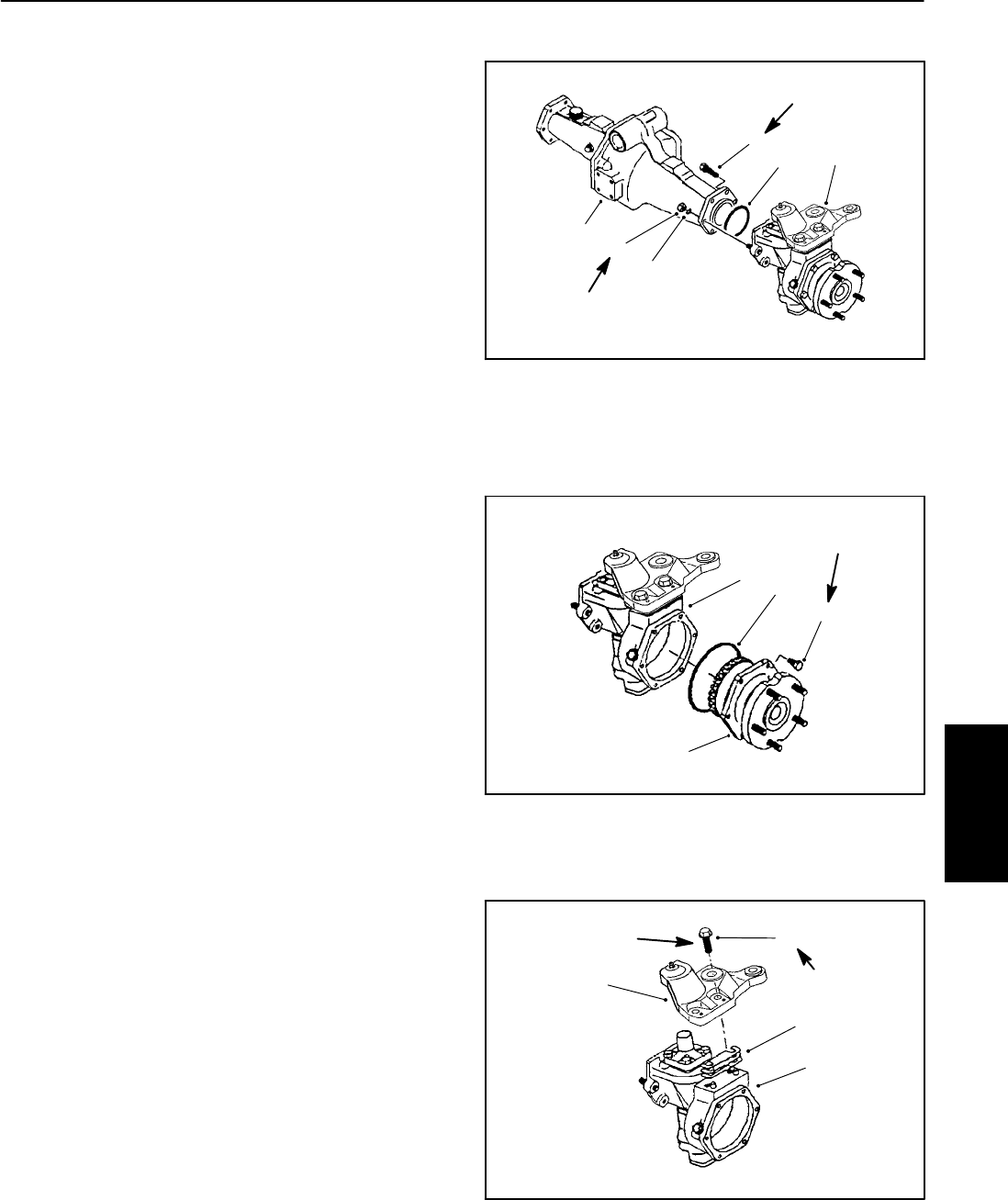

1. Remove the mounting screws, nuts and lock wash-

ers. Remove the bevel gear case/axle c ase assembly

and O-ring from the axle support (Fig. 15).

2. Mark both right and left bevel gear case/axle case

assemblies.

IMPORTANT: Do not interchange right and left bev-

el gear case/axle case assemblies.

1

2

3

4

5

6

1. Cap screw (4 used)

2. Lock nut (2 used)

3. Lock washer (2 used)

4. Axle support

5. Bevel gear case/axle

case assembly

6. O-ring

Figure 15

35 to 41 ft--lb

(47to56N--m)

35 to 41 ft--lb

(47to56N--m)

3. Remove the axle cover mounting screws. Remove

theaxlecoverfromtheaxlecaseasanassembly

(Fig. 16).

1. Axle case

2. Axle cover assembly

3. Mounting screw (6 used)

4. O-ring

Figure 16

1

2

3

4

17 to 20 ft--lb

(23to27N--m)

4. Remove the axle case support mounting screws, the

axle case support and the support shims (Fig. 17).

1. Axle case

2. Axle case support

3. Mounting screw (2 used)

4. Support shim

Figure 17

1

2

3

4

57 to 67 ft--lb

(77to91N--m)

Threadlocking

Compound

Axles, Planetaries

and Brakes