Greensmaster 3150 Hydraulic SystemPage 4 -- 61

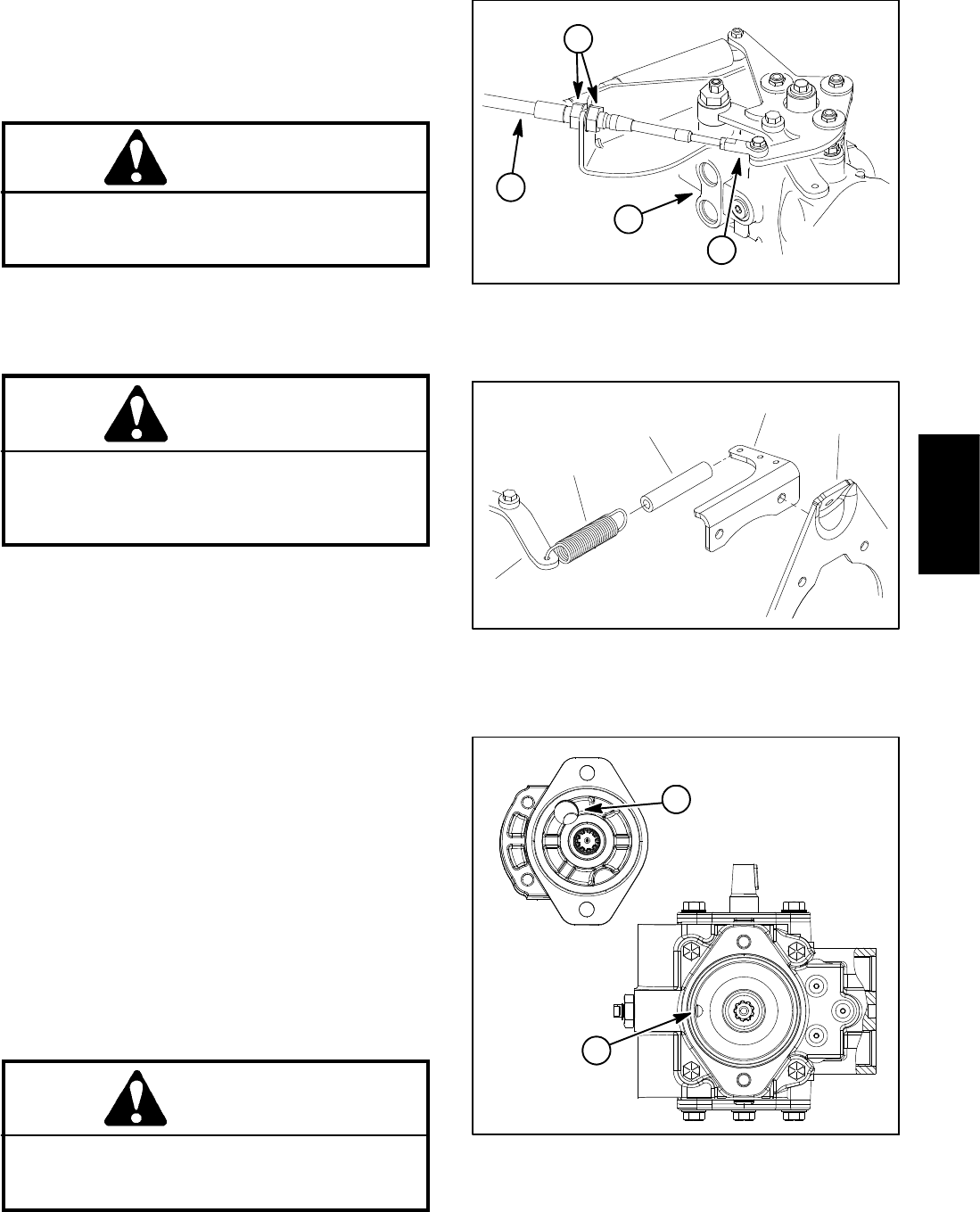

Piston Pump Removal (Fig. 42)

1. Park machine on a level surface, engage parking

brake, lower cutting units and stop engine. Remove key

from the ignition switch.

CAUTION

Before continuing further, read and become fa -

miliar with General Precautions for Removing

and Installing Hydraulic System Components.

2. Disconnect the traction control cable ball joint and

jam nuts from t he neutral arm (Fig. 43). Posit ion traction

cable away from the pump assembly.

CAUTION

The extension spring attached to the neutral arm

is under tension and may cause personal injury

during removal. Use caution when removing the

spring from the pump neutral arm.

3. Disconnect one end of the extension spring attached

to the neutral arm (Fig. 44).

4. Remove two (2) cap screws (item 10), flat washers

(item 9), coupling spacers (item 7) and lock nuts (item

6) that secure pump hub to rubber coupling (item 8).

5. Thoroughlyclean hydraulic hose ends andfittings on

gear and piston (traction) pumps to prevent hydraulic

system contamination.

6. Label all hydraulic hose connections on gear and

piston pumps for assembly purposes.

7. Clamp pump inlet hose (item 4) to prevent draining

the h ydraulic reservoir.

8. Loosen hose clamp and remove inlet hose from the

gear pump.

9. Disconnect hydraulic hoses from fittings on pump

assembly. Allow hoses to drain into a suitable container.

Plug hoses and fittings to prevent contamination.

CAUTION

Support the pump assembly when removing its

supporting fasteners to prevent it from falling

and causing personal injury.

10.Support pump assembly to prevent it from falling.

Figure 43

1. Piston pump

2. Traction cable

3. Jam nut (2 used)

4. Cable ball joint

2

1

4

3

1. Extension spring

2. Dampener hose

3. Spring bracket

4. Mount plate

5. Neutral arm

Figure 44

1

2

4

3

5

Figure 45

1. Piston pump case drain port

2. Gear pump suction port

2

1

Remove plugs

before installing

gear pump to

piston pump

Hydraulic

System