Greensmaster 3150 Page 6 -- 11 Chassis

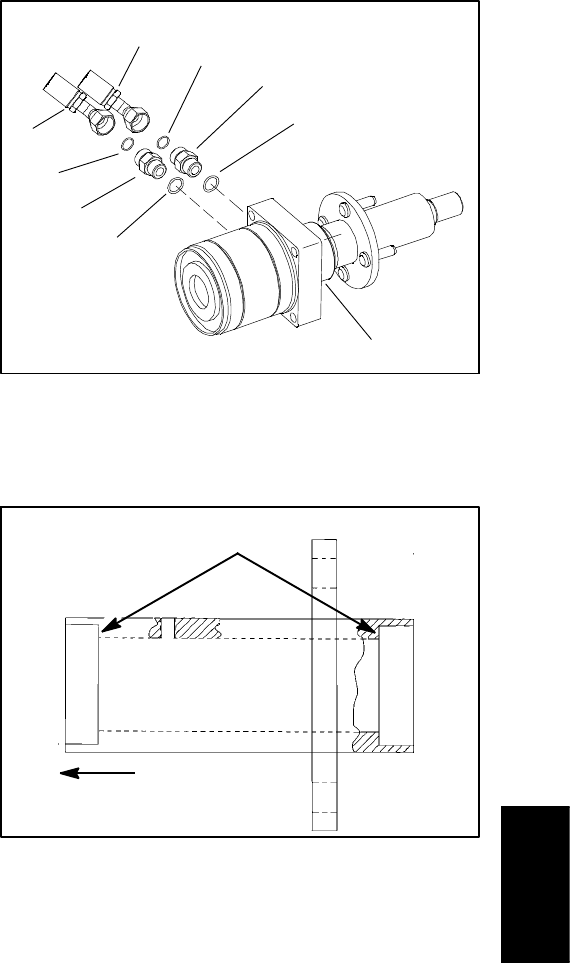

Assembly (Fig. 7)

1. If drive studs (item 4) were removed, press new

studs fully to the shoulder of the wheel hub.

NOTE: Arrow on the side of the clutch roller bearings

(item 3) must point to the long side of the end of the hub.

2. Press clutch roller bearings (item 3) into the hub as

follows (Fig. 9):

A. Press three (3) roller bearings into flange end of

the hub. The outer edge of the third bearing must be

flush with t he recessed edge within the hub.

B. Press final roller bearing into opposite end of hub.

The outer edge of the bearing must be flush with the

recessed edge within the hub.

C. The installed bearings must not interfere with

grease fitt ing hole in the hub.

3. Grease inner edge of the new grease seals (item 9)

with No. 2 multipurpose lithium base grease. Slide one

(1) seal onto motor shaft past groove closest to t he mo-

tor. Install snap ring (item 8) into groove.

4. Slide flat washer (item 7) and two (2) thrust washers

(item 6) onto the motor shaft. Slide hub onto the shaft

with the short end first.

5. Slide remaining thrust washers (item 6) and flat

washer (item 7) onto the motor shaft. Install remaining

snap ring (item 8) into the shaft groove. Slide remaining

new grease seal (item 9) onto motor shaft.

IMPORTANT: The hub should spin freely in the for-

ward direction, but lock on the hydraulic motor

shaft when it is rotated in the reverse direction.

6. Press grease seals (item 9) into the hub so they are

flushwiththeendofthehub.

7. Lubricate and position new O--rings to fittings on hy -

draulic motor. Use labels p laced during the removal pro-

cess to properly install hydraulic hoses to motor

adapters (see Hydraulic Hose and Tube Installation in

the General Information section of Chapter 4 -- Hydrau-

lic System).

8. Install rear wheel hub and motor assembly to rear

castor fork of machine (see Rear Wheel (Optional 3WD)

in this section).

1. Hub and motor assembly

2. O--ring

3. Adapter

4. O--ring

5. Hydraulic hose

6. Hydraulic hose

Figure 8

3

4

1

2

2

3

4

5

6

Figure 9

ARROWS ON BEARING

TOWARDS LONG END

OUTER BEARING EDGE

MUSTBEFLUSHWITHEDGE

Chassis