Greensmaster 3150Page 5 -- 26Electrical System

Leak Detector Float Sensor

The leak detector float sensor closely monitors the hy -

draulic fluid level in the main hydraulic tank. The sensor

contacts are open when the float is in the raised position

and oil level in the hydraulic tank is correct. The sensor

closes when the float is in the lowered position caused

by a low oil level and potential oil leak.

NOTE: For information on leak detector operation refer

to Turf Guardiant Leak Dete ctor System Operation in

this chapter.

Testing

1. If the float sensor is connected to the main harness,

remove hydraulic tank cap and screen from filler neck of

hydraulic tank. Turn ignition switch to the RUN position

(do not start the engine). Insert aclean rodor screw driv-

er into filler neck and gently push down on sensor float

(Fig. 33). Alarm should sound after a one (1) second

time delay.

2. If the float sensor is removed or disconnected from

the main harness, connect a continuity tester across the

float sensor wire terminals. There should be continuity

acrossthe terminals only when the float is pushed down.

There should be no continuity across the terminals

when the float is in the raised position.

3. If oil level sensor was removed from reservoir, install

oil level sensor into reservoir making sure that arrow on

sensor is pointing down (Fig. 34). Torque sensor nut

from 110to140in--lb(12.5to15.8N--m).

4. After testing, make sure that hydraulic oil level in res-

ervoir is correct.

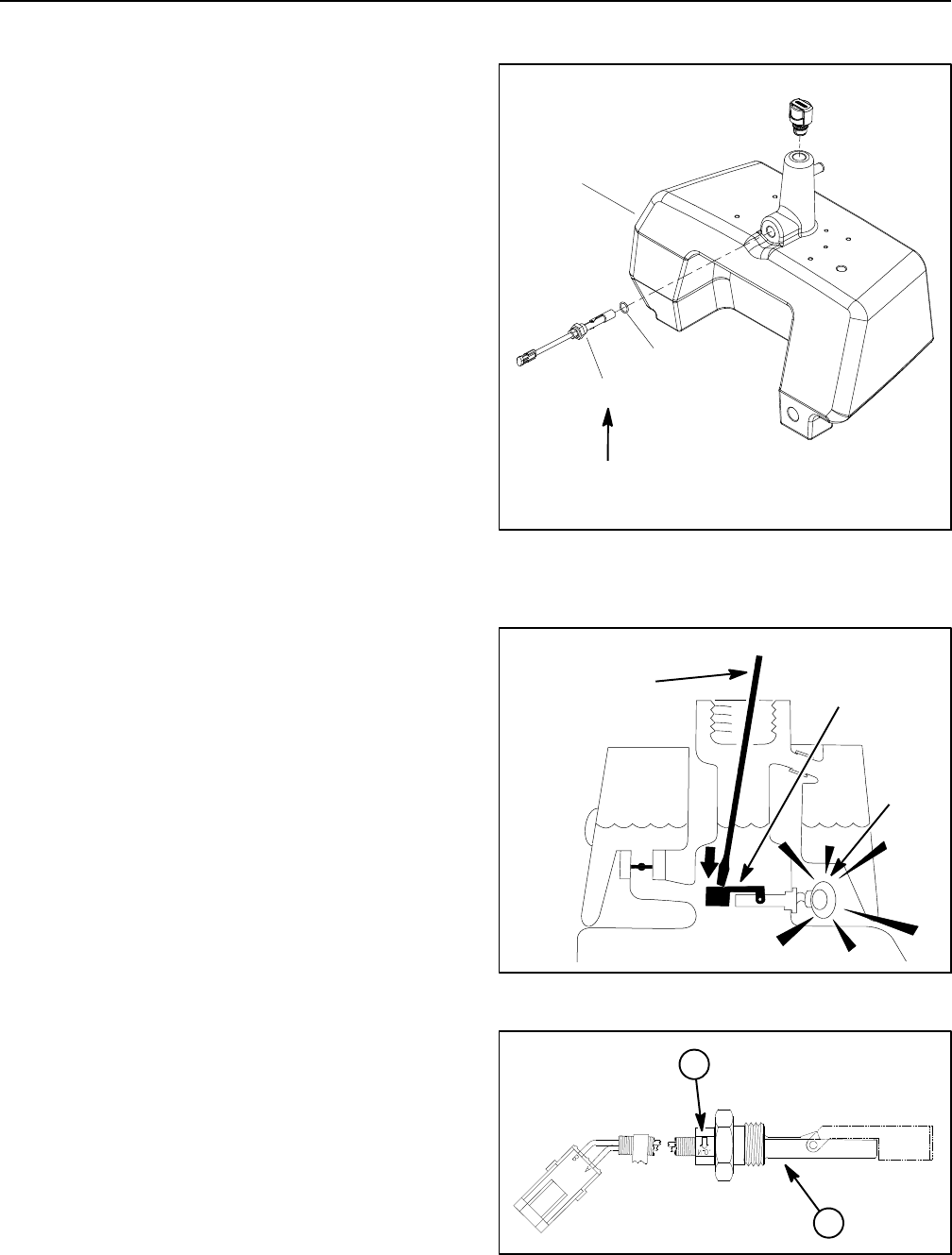

Figure 32

1. Main hydraulic tank

2. Float sensor

3. O--ring

110 to 140 in--lb

(12.5 to 15.8 N--m)

2

3

1

Figure 33

ALARM

(on)

FLOAT SENSOR

(lowered/closed)

CLEAN ROD OR

SCREWDRIVER

1. Oil level sensor 2. Sensor arrow

Figure 34

1

2