Greensmaster 3150 Hydraulic SystemPage 4 -- 37

Procedure for Implement Relief Valve Pressure

Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately ten

(10) minutes.

2. Park machine on a levelsurface withthe cutting units

lowered. Make sure engine is off. Make sure thehydrau-

lic tank is full.

CAUTION

Before continuing further, read and become fa -

miliar with Precautions for Hydraulic Testing.

3. Measure and record charge relief valve pressure

(see Charge Relief Valve Pressure Test in this section).

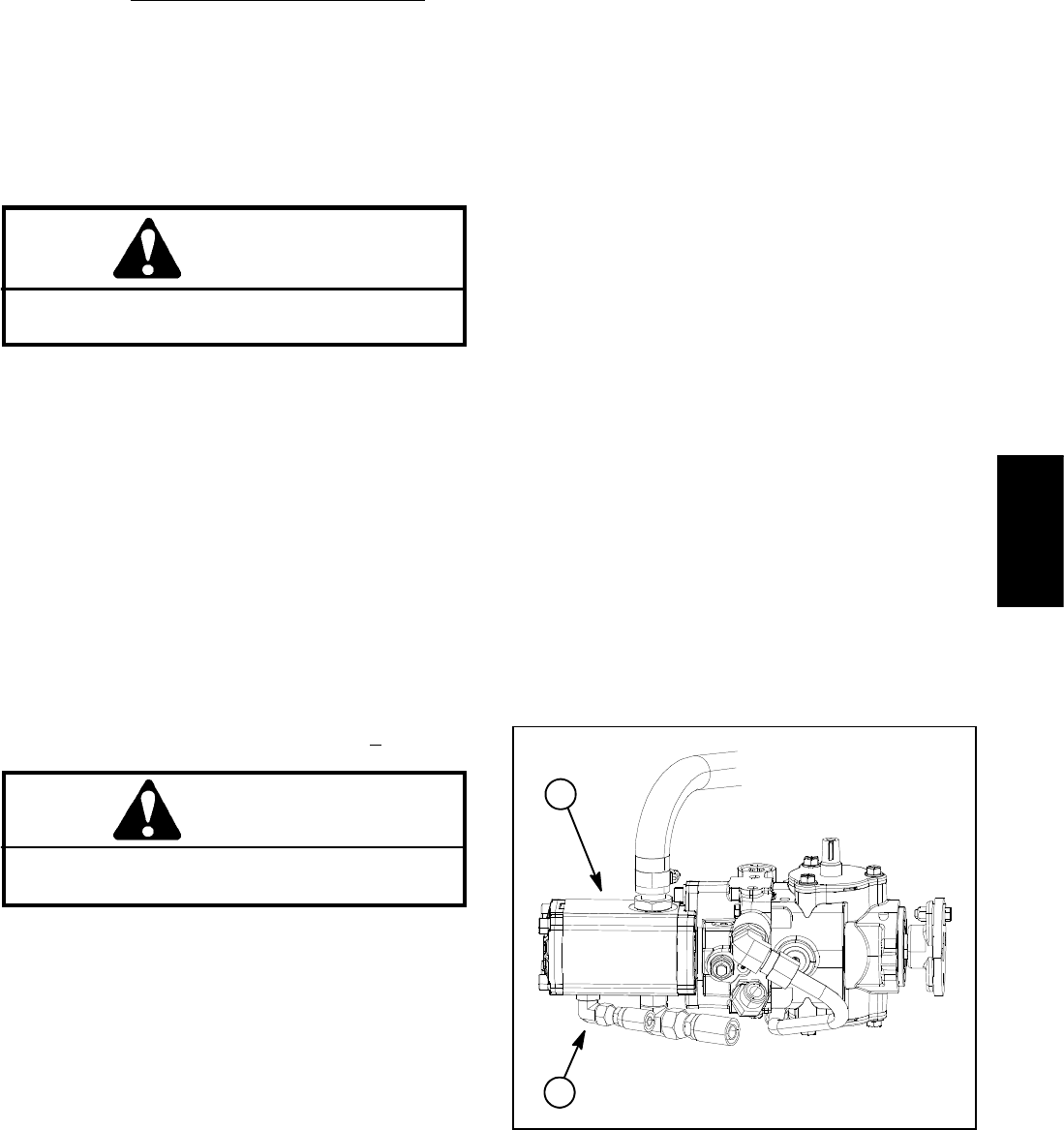

4. Thoroughly clean junction of hydraulic hose and the

hydraulic fitting in the rear gear pump section (Fig. 23).

This hose leads to port P in the steering valve.

5. Disconnect the hose from the fitting in the rear gear

pump section.

6. Install tester with p ressure gauge and flow meter in

series with the gear pump fitting an d the disconnected

hose (same connections as Gear Pump (Rear Section)

FlowTest).Make sureflow control valveon thetester

is fully open.

7. Start and run engine at full speed (2850 +

50 RPM).

CAUTION

When performing test, do not allow system pres-

sure to exceed 1400 PSI (83 bar).

8. Watch the pressure gauge on the tester and move

the joystick control to the raise position. Momentarily

hold the joystick with the cutting units fully raised caus-

ing the implement relief valve to open. Record pressure

at which the relief valve opens.

9. Release joystick to the neutral position and shut off

engine.

NOTE: The implement relief valve is in series with

charge relief valve. Charge relief pressure will affect the

implement r elief pressure.

10.Implement relief valve pressure should be 1050 to

1250 PSI (73 to 86 bar) higher than the charge relief

valve pressure (e.g. if the charge relief valve pressure

is 100 PSI (7 bar), the implement relief valve pressure

shouldbefrom1150to1350PSI(80to93bar)).

IMPORTANT: Hold steering wheel at full lock only

long enough to get a system pressure reading.

11.The implement relief valve is also activated by the

steering system. With tester still connected to gear

pump outlet, start engine and watch the pressure

gauge. Turn the steering wheel completely in one direc-

tion and hold. Relief valve should open just after rear

wheel gets to the full lock position. Relief pressure mea-

sured with the steering system should be similar to re-

sultsinstep10above.

12.If implement relief valve pressure is incorrect, in-

spect relief valve located in the steering valve (see

Steering Valve Service in the Service and Repairs sec-

tion of this Chapter). Clean relief valve or service steer-

ing valve as needed.

NOTE: Gear Pump (Rear Section) Flow Test and Low-

er Cutting Units Relief Valve Pressure can be measured

with tester positioned as described in this check (see

Gear Pump (Rear Section) Flow Test and Lower Cutting

Units Relief Valve Pressure Test in this section).

13.After testing is complete, remove tester from gear

pump fitting. Reconnect hose to the gear pump fitting.

1. Gear pump 2. Rear section fitting

Figure 23

1

2

Hydraulic

System