Greensmaster 3150 Page 3 -- 7 Engine

Engine Removal (Fig. 2)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Disconnect negative (--) battery cable from battery.

CAUTION

The muffler and exhaust manifold may be hot.

Avoid possible burns, allow exhaust system to

cool before working on the engine.

DANGER

Gasoline is flammable. Use cautionwhen storing

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank out-

side and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety-- ap-

proved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

3. Close fuel shut--off valve on fuel tank.

4. Remove the fuel hose support clamp and disconnect

fuelhose at the fuel pump (Fig. 3). Drainanyfueltrapped

in the fuel filter and fuel hose into a suitable container.

5. Disconnect the fuel evaporative control system

hoses from engine (see Fuel Evaporative Control Sys-

tem in this section).

6. Disconnect the engine wiring harness (item 29), the

choke control cable, the throttle control cable and the

ground wires (item 11) at the engine.

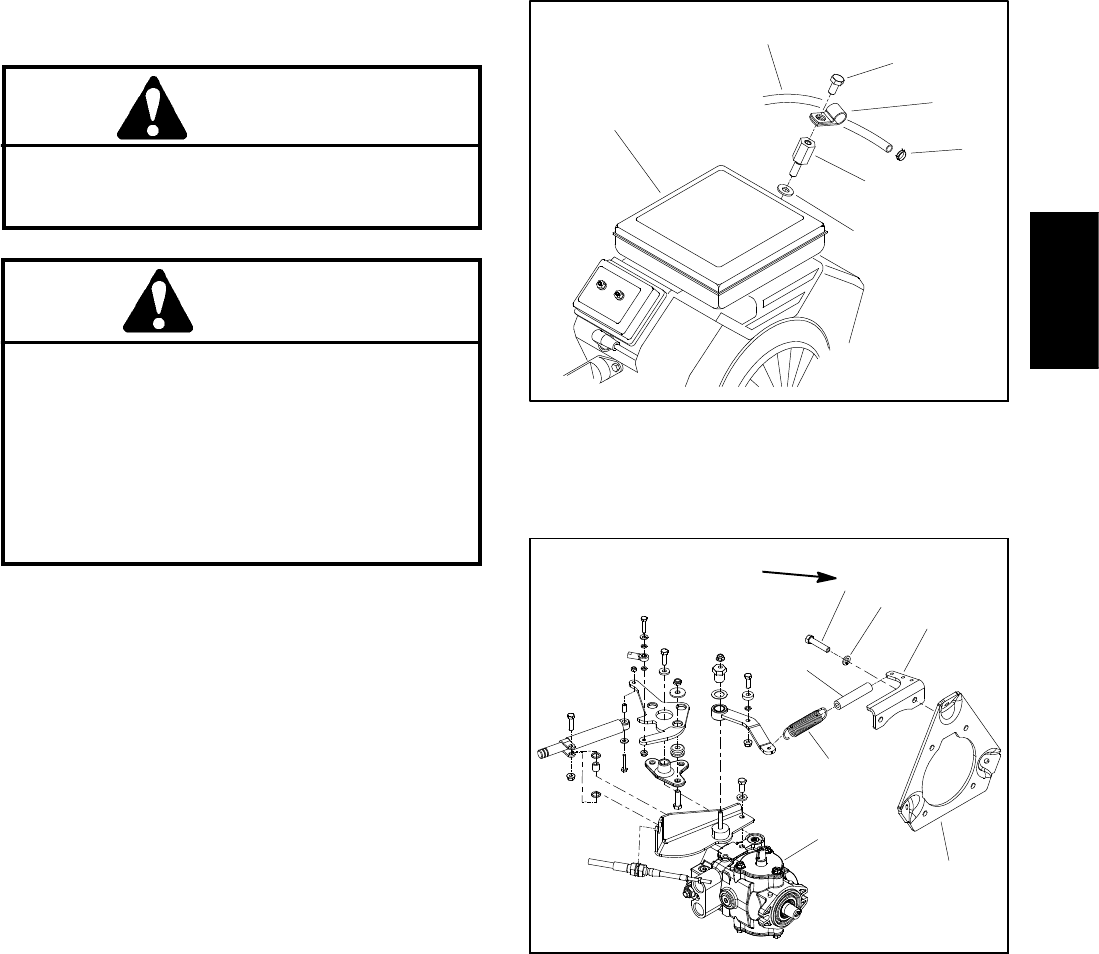

7. Carefully disconnect extension spring on piston

pump control assembly from spring bracket that is at-

tached to engine mount plate (Fig. 4).

8. Loosen the two (2) set screws (item 47) securing the

engine hub (item 41) to the engine shaft.

9. Support the piston pump assembly and remove the

two (2) cap screws (item 53), lock washers (item 52) and

hardened washers (item 51) securing the pump to the

pump adapter (item 19). Do Not disconnect the hydrau-

lic hoses or neutral control linkage from the pump.

10.Support the engine assembly and remove the three

(3) e ngine mount flange nuts (item 7), cap screws (item

1), flat washers (item 2) and spacers (item 3).

11.Carefully move the engine away from the piston

pump until the crankshaft clears the engine hub. Re-

move the engine from the machine. Locate and retrieve

key (item 48) from crankshaft.

Figure 3

1. Engine assembly

2. Fuel supply hose

3. Cap screw

4. Support clamp

5. Hose clamp

6. Spacer screw

7. Washer

2

3

6

1

5

7

4

Figure 4

1. Engine mount plate

2. Spring bracket

3. Lock washer (2 used)

4. Cap screw (2 used)

5. Dampener hose

6. Extension spring

7. Piston pump assembly

2

3

6

1

5

7

4

25 to 38 ft--lb

(34to51N--m)

Engine Installation (Fig. 2)

1. Make sure that all parts removed from the engine

during maintenance or rebuilding are installed to the en-

gine.

2. Apply antiseize lubric ant to bore of engine hub.

Place key (item 48) into slot on the engine crankshaft.

Engine