Greensmaster 3150

DPA Cutting Units

Page 7 -- 34

IMPORTANT: The brush drive belt may fail prema -

turely if the pulleys are not properly aligned.

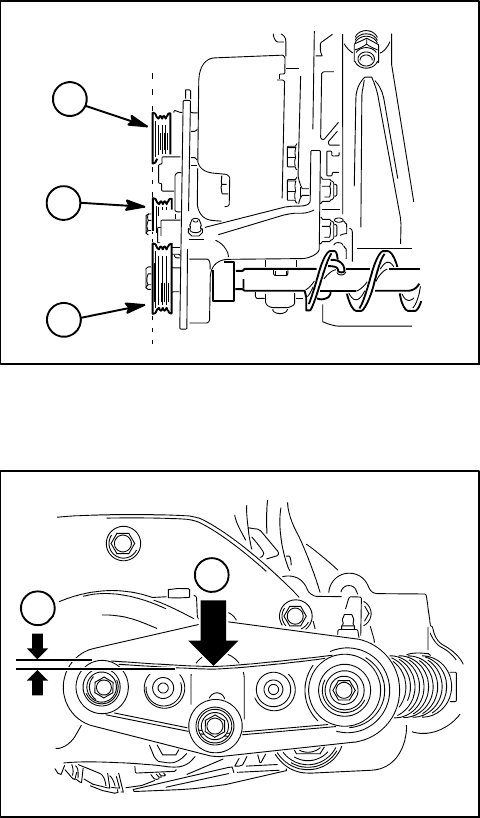

4. Check alignment of pulleys with a straight edge

placed along the outer face of the pulleys (Fig. 37). The

outer faces of the drive, driven and idler pulleys should

be aligned. If necessary to align pulleys, loosen locking

collars on brush bearings andmove brush assembly un-

til pulleys are aligned. Once pulleys ar e aligned, secure

brush with bearing locking collars.

IMPORTANT: Make sure that idler pulley is loos-

ened before installing brush drive belt.

5. To install b rush drive belt (item 2):

A. Make sure that idler pulley ( item 6) is loose on

drive plate.

B. Carefully install drive belt around drive, driven

and idler pulleys.

C. After belt installation, make sure that belt and

pulley grooves are aligned and thatbelt is centered in

pulleys.

6. To tension the drive belt:

A. Pushdown on the idler pulley and secure with cap

screw (item 22) and flange nut (item 8). Make sure

that cover plate (item 7) is covering the slot in the

drive plate to prevent debris from entering the brush

drive area.

B. After idler pulley is secured, check that drive belt

has approximately 1/4” (6 mm) deflection at the cen-

ter of the belt with 2 lb (1 kg) of force applied to the

belt (Fig. 38).

7. Check that roller brush is parallel to rear roller with

0.010” (0.25 mm) clearance to light contact with roller.

If contact is incorrect, brush operation will be adversely

affected.

8. Lubricate grease fittings on brush support and drive

plate until grease is visible. Wipe up excess grease.

1. Drive pulley

2. Driven pulley

3. Idler pulley

Figure 37

2

3

1

Figure 38

1. 2 lb (1 kg) of force 2. 1/4” (6 mm) deflection

1

2