Groundsmaster 4500--D/4700--D Hydraulic SystemPage 4 -- 59

Procedure for Cutting Deck Circuit Relief Pressure

Test

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

1. Make sure hydraulic oil is at normal operating tem-

perature by operatingthe machinefor approximately ten

(10) minutes. Make sure the hydraulic reservoir is full.

2. Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is engaged.

3. Determine cutting deck circuit relief pressure to be

tested:

A. For the first gear pump section (decks #2, #3, #5

and #7), cutting deck circuit relief (PRV2) is tested at

the inlet to the deck #5 motor (Fig. 49).

B. For second gear pump section (decks #1, #4 and

#6), cutting deck circuit relief (PRV1) is tested at the

inlet to the deck #1 motor (Fig. 49).

4. Thoroughly clean junction of appropriate hydraulic

inlet hose and deck motor fitting (Fig. 50). Disconnect

the hydraulic inlet hosefromthedeckmotor.

IMPORTANT: Make sure that the oil flow indicator

arrow on the tester is showing that the oil will flow

from the disconnected hose, through the tester and

into the deck motor.

5. Install tester with pressure gauge and flow meter in

series with the disconnected hose and deck motor inlet.

Make sure the tester flow control v alve is fully open.

6. After installing pressure gauge, start engine and run

at low idle speed. Check for hydraulic leakage and cor-

rect before proceeding with test.

CAUTION

Keep away from decks during test to prevent per-

sonal injury from the cutting blades.

7. Increase engine speed to high idle speed. Engage

the cutting decks.

8. Watch tester pressure gauge carefully while slowly

closing the flow control valve on tester.

9. As the circuit relief valve lifts, system pressure

should be from 3400 to 3750 PSI (235 to 258 b ar).

10.Open the tester flow control valve, disengage cutting

decks and stop the engine. Record test results.

11.If specification is not met, make sure that electrical

connections at deck control manifold are secure and

then clean or replace relief valve (PRV1 or PRV2) in the

deck control manifold (see Deck Control Manifold Ser-

vice in the Service and Repairs section of this chapter).

Also, if pressure is still low after relief valve service,

check for restriction in pump intake line. The first or

second gear pump section could also be suspected of

wear or damage (see Gear Pump Flow Test in this sec-

tion).

12.After testing is complete, disconnect tester from

deck motor and hose. Connect hydraulic hose to motor.

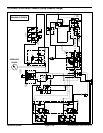

Figure 49

#4 Deck #1 Deck #5 Deck

#7 Deck

(GM4700)

#6 Deck

(GM4700)

#3

Deck

#2

Deck

CUTTING DECK LOCATIONS

1. Flow IN

2. Flow OUT

3. Case drain

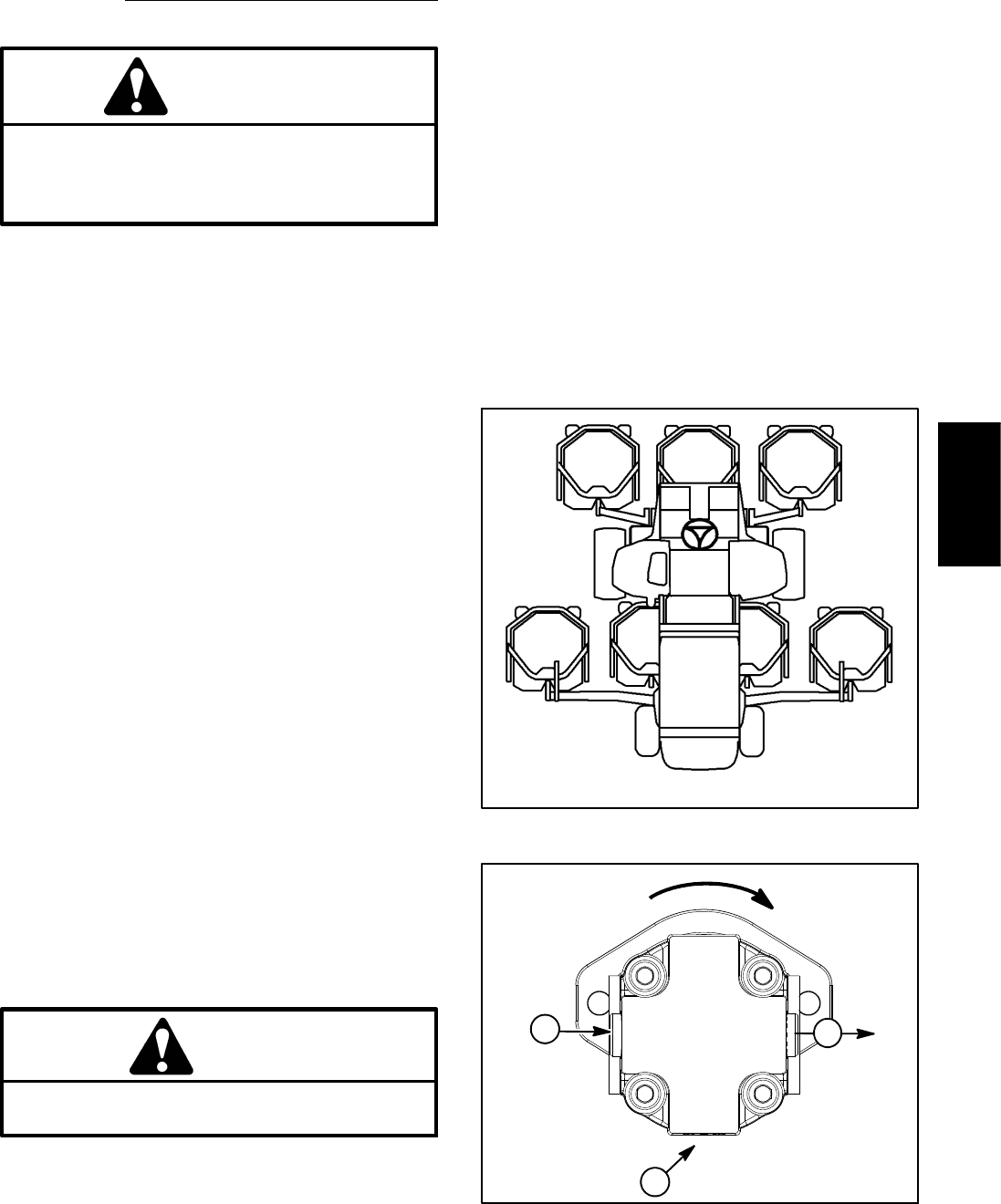

Figure 50

Rotation Direction

2

1

3

Hydraulic

System