Groundsmaster 4500--D/4700--DHydraulic System Page 4 -- 70

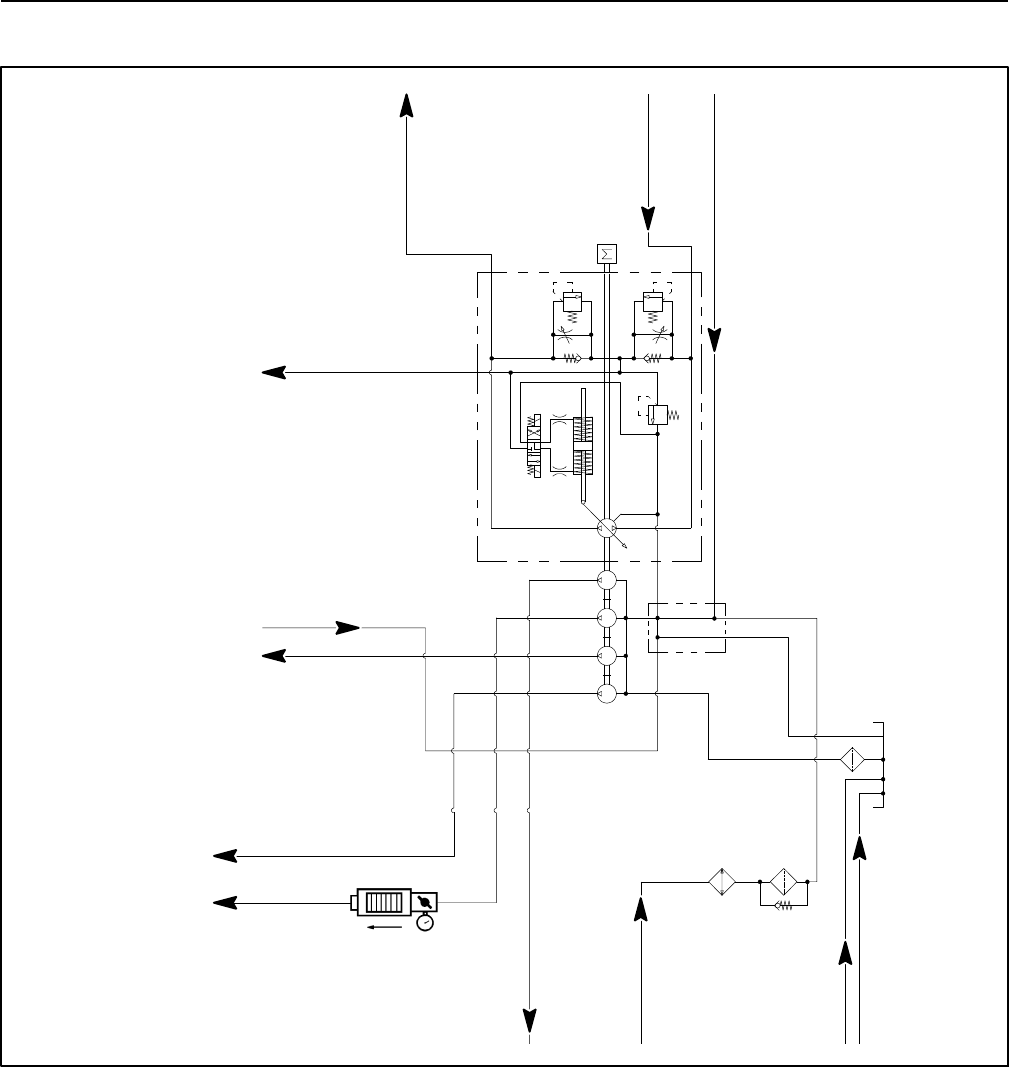

Gear Pump Flow (Using Tester with Pressure Gauge & Flow Meter)

SECOND GEAR

PUMP SECTION

TESTER

4350 PSI

250 PSI

5000 PSI

EU -- 2600 /1200 RPM

0.56

CID

0.56

CID

1.03

CID

1.03

CID

2.75

CID

50

PSI

ENGINE

T4 -- 2700 /1200 RPM

PISTON

PUMP

FROM REAR

TRACTION VALVE

REAR DECK & COOLING FAN

MOTOR CASE DRAIN

CASE DRAIN

FRONT DECKMOTOR

FROM STEERING

TRACTION

CONTROLVALVE

FLOW

MANIFOLD PORT P1

TO F AN CONTROL

TODECK CONTROL

MANIFOLD PORT P1

CHARGE

CIRCUIT

FROM WHEEL MOTOR CASE DRAIN

CIRCUITFLOW

TODECK CONTROL

MANIFOLD PORT P2

MANIFOLD PORT P2

TO FAN CONTROL

FROM DECKCONTROL

MANIFOLD PORTT1

FLOW TEST SHOWN

The gear pump flow test should be performed to make

sure that the mow, steering, lift/lower, cooling fan and

traction charge circuits have adequate hydraulic flow.

Gear pump sections are illustrated in Figure 57. The first

gear pump section provides hydraulic flow for cutting

decks 2, 3 and 5 (also deck 7 on the GM 4700--D). The

second gear pump section provides hydraulic flow for

cutting decks 1 and 4 (also deck 6 on the GM 4700--D).

The third gear pump section provides hydraulic flow for

the steering, lift/lower and traction charge circuits. The

fourth gear pump section provides hydraulic flow for the

engine cooling fan circuit.

NOTE: Overaperiodoftime,thegearsandwearplates

in the gear pump can wear. A worn pump will by pass oil

and make the pump less efficient. Eventually,enough oil

loss will occur to cause circuit problems (e.g. cutting

deck motors stalling under heavy cutting conditions, lift

or steering problems). Continued operation with a worn,

inefficient gear pump can generate excessive heat and

cause damage to the seals and other components in the

hydraulic system.