Groundsmaster 4500--D/4700--D Page 3 -- 21 Yanmar Diesel Engine

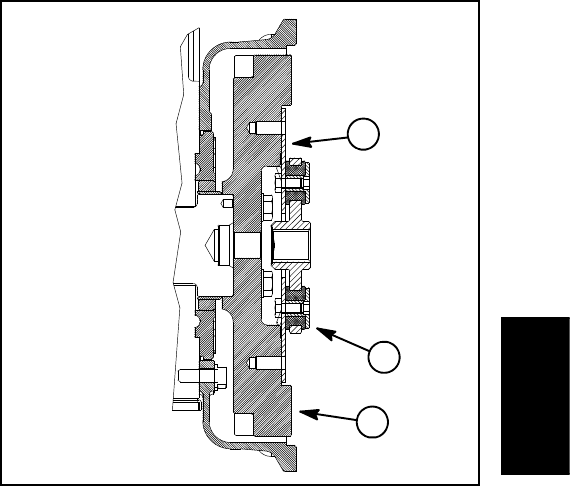

Coupler Removal (Fig. 17)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before coupler can be removed.

1. If engine is in machine, remove hydraulic pump as-

sembly (see Piston (Traction) Pump in the Service and

Repairs section of Chapter 4 -- Hydraulic System).

2. Remove flywheel plate and spring coupler from en-

gine using Figure 17 as a guide.

Coupler Instal lati on (Fig. 17)

1. Position spring coupler to engine flywheel and align

mounting holes. Make sure that coupling hub is away

from engine flywheel (Fig. 18).

2. Secure coupler to flywheel with eight (8) cap screws

and hardened washers.Torque cap screwsin a crossing

pattern from 29 to 33 ft--lb (40 to 44 N--m).

3. Position flywheel plate to engine. Make sure that

boss on plate is orientated down. Secure flywheel plate

with eight (8) cap screws (item 7) and hardened wash-

ers. Torque cap screws in a crossing pattern from 29 to

33ft--lb(40to44N--m).

4. If engine is in machine, install hydraulic pump as-

sembly (see Piston (Traction) Pump in the Service and

Repairs section of Chapter 4 -- Hydraulic System).

Figure 18

1. Coupler

2. Coupler hub

3. Engine flywheel

Engine Side Hydraulic

Pump Side

1

2

3

Yanmar

Diesel Engine