Greensmaster 3320/3420Groomer Page 9 -- 18

Grooming Reel Bearing Replacement

Bearing Removal

1. Park machine on a clean, level surface. Lower cut-

tingunits completely to theground,stop engine,engage

parking brake and remove key from the ignition switch.

2. Disconnectthecutting units from the electricalpower

supply by separating the cutting unit power disconnect

couplers (see Opening Electrical Circuitto Cutting Units

in the General Information section of this chapter). This

will prevent unexpected cutting unit operation.

3. Remove the cutting unit from the machine and place

cutting unit on a flat work area.

4. To remove groomer drive plate assembly from right

side of cutting unit, remove front roller, grooming reel

andthendrive plate assembly(see GroomingReel(For-

ward Rotating or Counter Rotating) in this section).

5. To remove support plate assembly from left side of

cutting unit (Fig. 19):

A. Remove two (2) socket head screws and lock

nuts that secure motor mount tocutting unit(Fig. 19).

Remove motor mount from cutting unit.

B. Remove lock nut and spring washer that secure

LH groomer arm liftrod tosupport plate(Fig. 20).Re-

move support plate from cutting u nit.

6. Remove grooming reel seals and bearings from RH

drive plate and LH support plate assemblies (Figs. 21,

22 and 23). Discard all removed seals and bearings.

Bearing Installation

1. Installnew grooming reelbearings and sealsinto RH

drive plate and LH support plate assemblies ( Fig. 24):

IMPORTANT: Bearings should be installed with ex-

tended inner races toward center of housing. Also,

apply pressure equally to inner and outer bearing

races when installing bearings.

A. Press new outer bearing fully to shoulder of RH

drive plate bore. Then, install new inner bearing until

inner race contacts outer bearing race.

B. Press new bearing into LH support plate u ntil it is

flush with shoulder of bearing bore.

C. Installnewsealsinto groomer sideplates.NOTE:

Seals should be installed so the lip side of the seal

will facethe center ofthe cutting reel. Whenbearings

are greased, grease will purge from inner seals.

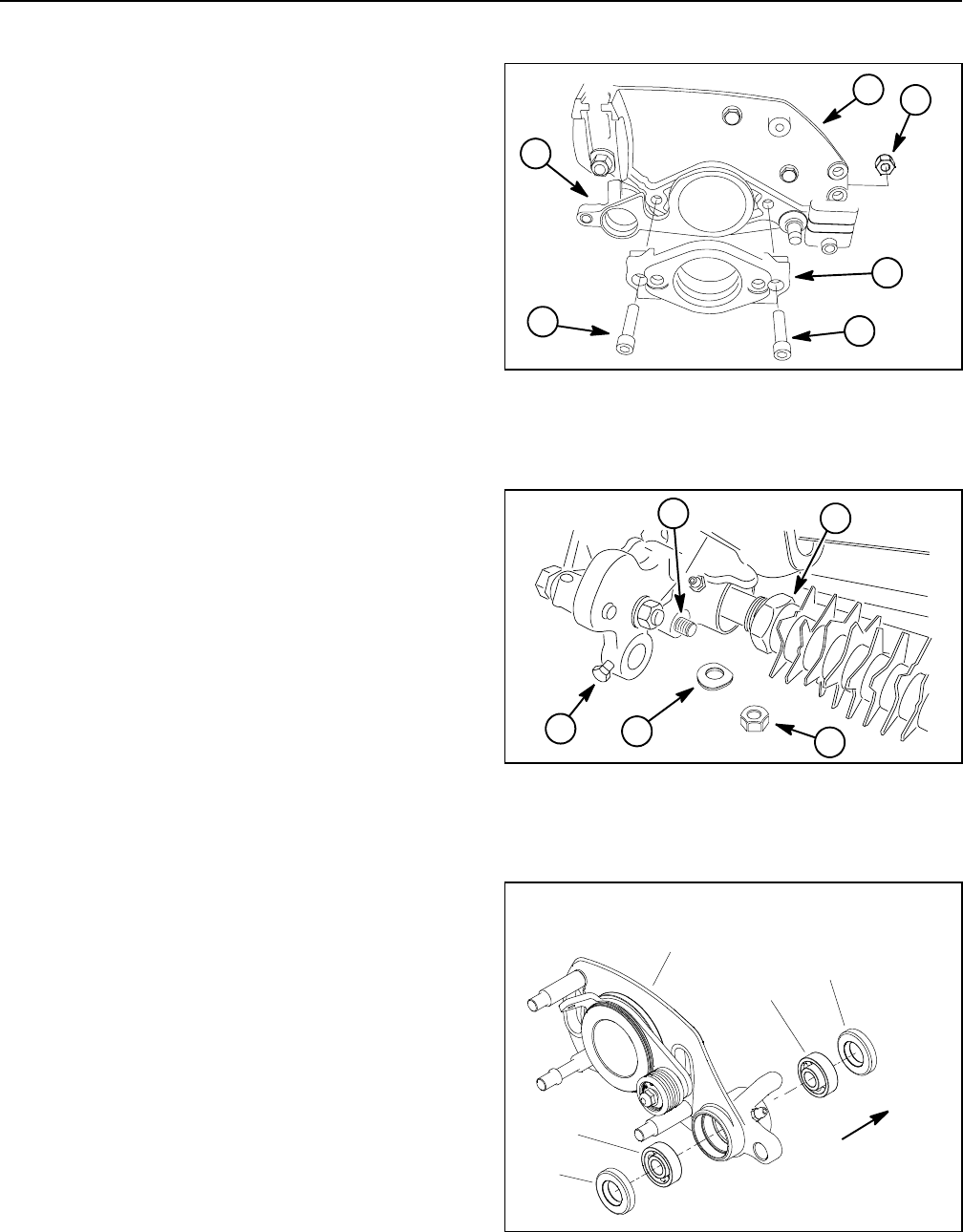

1. Socket head screw

2. Motor mount

3. Groomer side plate (RH)

4. Cutting unit

5. Lock nut (2 used)

Figure 19

4

2

1

3

1

5

1. Front roller cap screw

2. Grooming reel assembly

3. Lock nut

4. Spring washer

5. Groomer arm lift rod

Figure 20

4

2

1

3

5

1. RH drive plate assy

2. Bearing (2 used)

3. Seal (2 used)

Figure 21

Seal lips

(toward center of

cutting unit)

3

2

2

3

1

FORWARD ROTATING GROOMER