Greensmaster 3320/3420 Page 7 -- 25 Chassis

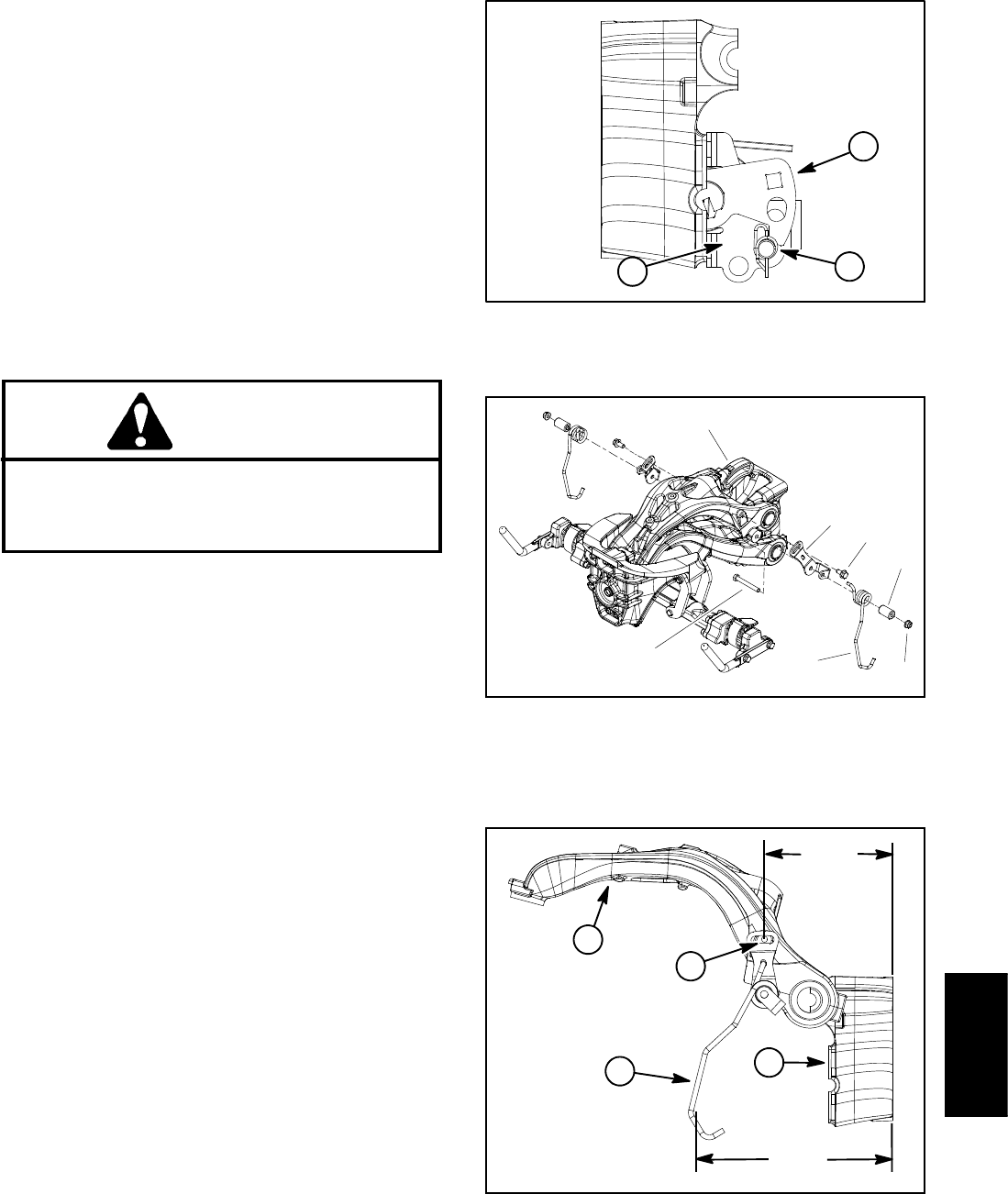

Disassembly (Fig. 20)

1. If cutting unit suspension is attached to machine:

A. Park machine on a level surface, engage the

parking brake, lower the cutting units and stop the

engine. Remove key from the ignition switch.

B. Disconnect the cutting units from the electrical

power supply by separating the cutting unit power

disconnect couplers (see Opening Electrical Circuit

to Cutting Units inthe General Information section of

this chapter). This will prevent unexpected cutting

unit operation.

2. Remove tension from suspension counterbalance

assembly:

CAUTION

Be careful when removing tension f rom the sus-

pension counterbalance system. The counter-

balance spring is under heavy load and may

cause personal injury.

A. Remove cotter pin f rom clevis pin that secures

counterbalance tensioner arm.

B. Use 3/8” drive breaker bar in tensioner arm

square drive hole to hold tensioner arm in place so

that clevis pin can be removed.

C. Remove clevis pin and allow counterbalance

springs to relax.

3. Disassemble suspension assembly as required us-

ingFigure20asaguide.

NOTE: Medium strength Loctite #609 retaining com-

pound is applied to ball joint housing during assembly.

Localized heat around the ball joint housing will allow

easier ball joint removal from A--arm.

Assembly (Fig. 20)

1. Install all removed suspension assembly compo-

nents using Figure 20 as a guide.

A. Ifany ball joint(item3) wasremoved fromA--arm,

clean ball joint housing and A--arm bore with Loctite

cleaning solvent (or equivalent) and allow to dry. Ap-

ply Loctite #609 retaining compound (or equivalent)

to ball joint housing before inserting ball joint into A--

arm.

B. If any clamp (item 9) was removed, make sure

thatraised boss inclampbore is positioned ingroove

of ball joint stud before securing clamp.

1. Clevis pin

2. Counterbalance mount

3. Tensioner arm

Figure 21

2

1

3

1. Suspension assembly

2. Cap screw

3. Spring retainer

4. Flange head screw

5. Spacer

6. Flange nut

7. Stabilizer spring

Figure 22

1

3

5

7

4

6

2

1. Stabilizer spring

2. Upper a--arm

3. Pivot mount

4. Spring hole

Figure 23

2

1

3

8.760”

(222.5 mm)

5.710”

(145.0 mm)

4

Chassis