Rev. A

Greensmaster 3320/3420

DPA Cutting Units

Page 8 - 25

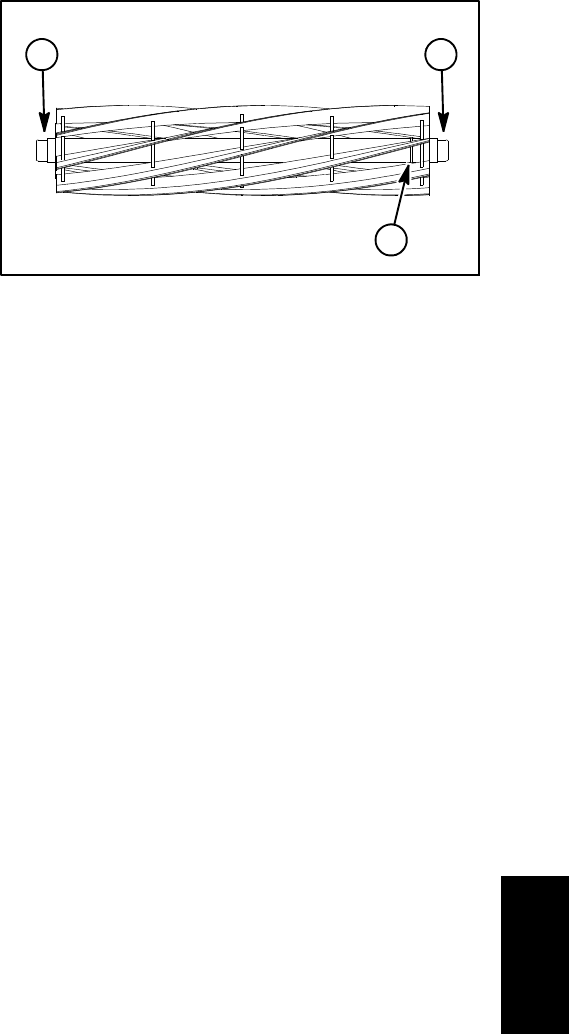

Disassembly of Cu tting Reel (Fig. 24)

1. Remove bearing lock screw (item 5) and reel nut

(item 6) from cutting reel. Reel nut has LH threads and

is in end of reel shaft identified with a groove that is just

inside of reel spider (Fig. 25).

2. Slide bearings from reel shaft.

IMPORTANT: The reel shaft bearing journals are

painted. Proper bearing fiton thereel shaftincludes

having the paint on theshaft to ensure correct bear-

ing clearance. DO NOT remove paint from the reel

shaft bearing journals when servicing the cutting

reel.

3. Note orientation of flocked seals for assembly pur-

poses. Remove seals from reel shaft.

Inspection of Cutting Reel (Fig. 24)

1. Inspect reel bearings to insure that they spin freely

and have minimal axial play.

2. Inspectthe reel shaftas follows. If reel damage isde-

tected, replace reel.

A. Check the reel shaft for bending and distortion by

placing the shaft ends in V- blocks.

B. Check the reel blades for bending or cracking.

C. Check the service limit of the reel diameter (see

Preparing a Reel for Grinding in this section).

D. Check threads in ends of reel shaft.

3. Check the splines in the reel nut (item 6) for exces-

sive wearor distortion. Replace reelnutif damageis evi-

dent.

Assembly of Cutting Reel (Fig. 24)

1. If bearings and/or flocked seals were removed from

reel shaft, discard removed components and replace.

IMPORTANT: The flocked seal should be installed

so the flocked side of the seal is toward the bearing

location.

2. Slide flocked seals ( flocked side orientated toward

bearing location) and bearings fully onto reel shaft.

Bearings and seals should bottom on reel shaft shoul-

der.

3. Install bearing lock screw (item 5) and reel nut (item

6) into reel shaft to secure bearings. Reel nut has LH

threads andshould be installed in end ofreel shaft iden-

tified with a groove that is just inside of reel spider (Fig.

25).

NOTE: Installation torque for bearing lock screw and

reel nut is from 90 to 110 ft- lb (123 to 149 N- m).Itis

easiest to torque these items after the cutting reel is

installed in the cutting unit frame (see Reel Assembly

Removal and Installation in this section).

4. Thoroughly fill spline area of reel nut (left side of cut-

ting reel) with grease.

1. LH threads

2. Groove

3. RH threads

Figure 25

1

2

3

DPA Cutting

Units