Greensmaster 3320/3420 Page 6 -- 57 Electrical System

Toro Electronic Controller (TEC)

GreensmasterTriFlexHybridmachines use aToro E lec-

tronic Controller (TEC) to monitor the condition of vari-

ous switches (inputs) and then direct electrical power

output to allowcertain machinefunctions.The controller

is attached to the frame under the operator seat (Fig.

70). TEC inputs and outputs on your Greensmaster can

be checked with the Hand Held Diagnostic Display (see

Hand Held Diagnostic Display in the Troubleshooting

section of t his chapter) or InfoCenter Display (see

InfoCenter Display in this chapter).

Inputs from the ignition, neutral, parking brake, seat,

joystick, mow, backlap and engine oil pressure are all

monitored by the TEC controller. TEC inputs on Green-

smaster 3420 machines also include the alternator, en-

gine temperature sender and optional hydraulic

temperature sender (if equipped). TEC inputs on

Greensmaster 3320 machines also include the leak de-

tector sensor if equipped with the optional Turf Defen-

der

TM

Leak Detector.

On all Greensmaster TriFlex Hybrid machines, TEC

controller current output to the lift circuit hydraulic valve

solenoidcoils (S1, S2,S3 and S4)and console diagnos-

tic light (if equipped) are controlled based on the inputs

received by the controller. TEC outputs on Greensmas-

ter 3320 machines also include the start solenoid, fuel

solenoid, charge circuit relay, kill relay and optional Turf

Defender

TM

Leak Detector indicator light and alarm.

TEC outputs on Greensmaster 3420 machines also in-

clude the start relay, glow relay, fuel pump, engine run

solenoid (hold coil), fan relay and console indicator

lights (if equipped).

If the controller detects a malfunction in any of the con-

trolled circuits, the diagnostic light or InfoCenter Display

canbeusedtoidentifythefault.

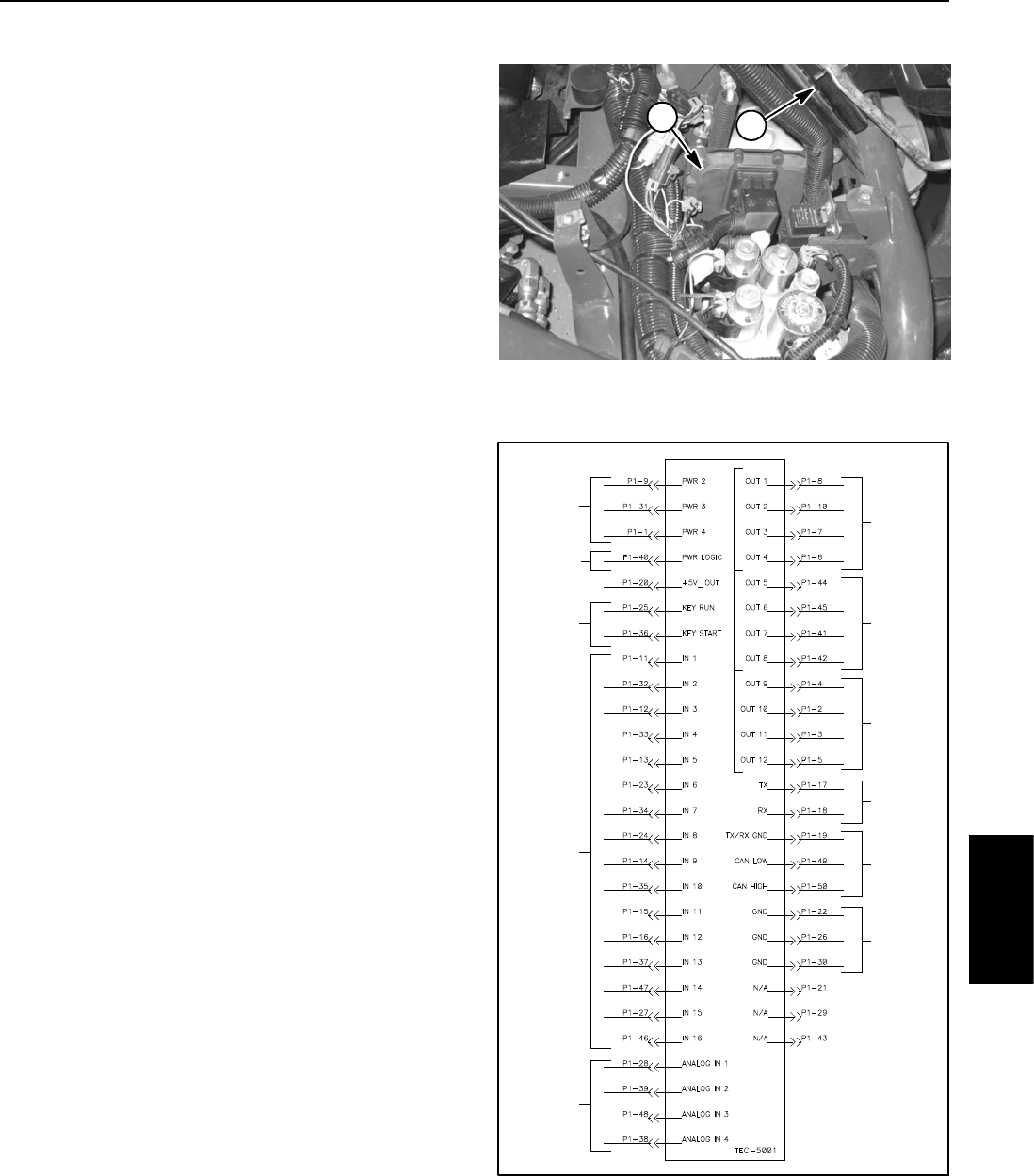

The diagram in Figure 71 depicts the connection termi-

nal functions of the T EC controller. A fifty (50) pin wire

harness connector attaches to the controller. The con-

nector pins are listed in the diagram. Note that electrical

powerforcontroller outputsis providedthroughthree(3)

connectors each protected with a 7.5 amp fuse.

Because of the solid state circuitry built into the control-

ler, there is no method to test it directly. The controller

may be damaged if an attempt is made to test it with an

electrical test device, such as a digital multimeter.

IMPORTANT: Before welding on the machine, dis-

connect both battery cables from the battery, dis-

connect the wire harness connector from the TEC

controller and disconnect the terminal connector

from the alternator. This will prevent damage to the

electrical system of your Greensmaster.

Figure 70

1

1. TEC controller location 2. Seat platform

2

Figure 71

12V POWER

(7.5AFUSES)

12VLOGIC

IGNITION

SWITCH

INPUTS

DIGITAL

INPUTS

(OPEN/

ANALOG

INPUTS

POWER

(2AMPFUSE)

DIAGNOSTIC

DISPLAY

CANBUS

CLOSED)

OUTPUTS

(PWR2)

GROUND

(VARIABLE)

OUTPUTS

(PWR3)

OUTPUTS

(PWR4)

Electrical

System