Greensmaster 3320/3420Page 6 -- 60Electrical System

Main Power, Electric Cutting Reels Enable, Charge Circuit (Greensmaster 3320), Glow

(Greensmaster 3420) and Fan (Greensmaster 3420) Relays

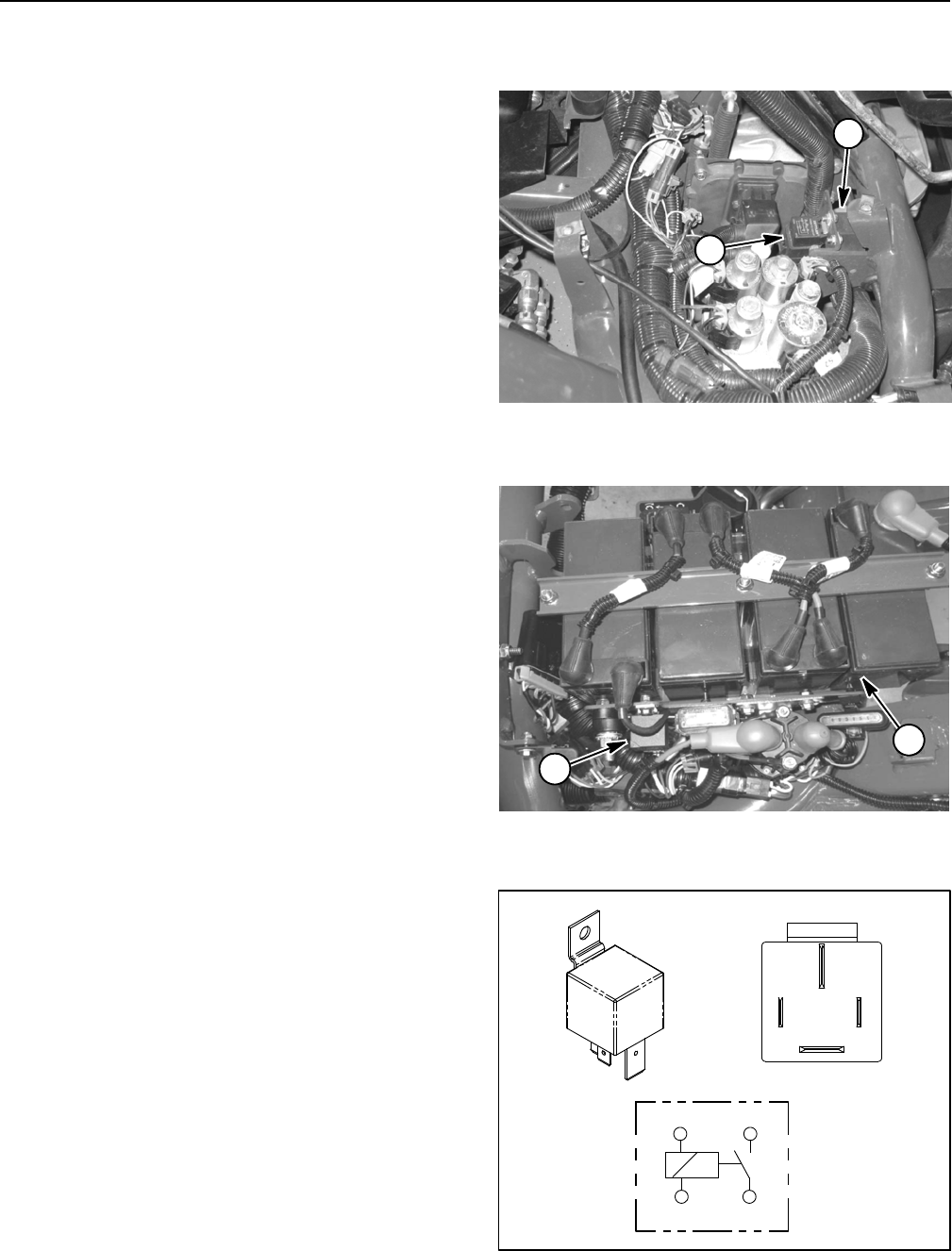

The Greensmaster TriFlex Hybrid electrical system in-

cludes several identical, four (4) terminal relays for cur-

rent control. Most of these relays are located under the

right side cover next to the operator seat (Fig. 74). The

electric cutting reels enable relay is located under the

left side covernext to theoperator seat (Fig.75). Relays

canbeidentifiedbyatagneartherelaywireharness

connector.

The main power relay provides electrical current to the

fuse blocks when energized by the ignition switch in the

RUN or START position. The main power relay is used

on both Greensmaster 3320 and 3420 machines.

The electric cutting reels enable relay is used to provide

48V logic power tothe generator andreel motor control-

lers. It also supplies power to the main contactor in the

electric reel circuit. This relay is energized by an output

from the TEC controller. The reels enable relay is used

on both Greensmaster 3320 and 3420 machines.

The charge circuit relay used on Greensmaster 3320

machines provides a current path for alternator output

toreachthemachine’selectricalsystem.Thechargecir-

cuit relay is energized by the Toro Electronic Controller

(TEC) when the ignition switch is in RUN or START.

The glow relay used on Greensmaster 3420 machines

provides electrical current to the engine glow plugs

when energized by the TEC controller.

The fan relay used on Greensmaster 3420 machines

provides electrical current to the engine cooling fan

when energized by the TEC controller. The fan relay is

energized when engine coolant temperature reaches

approximately 185

o

F(85

o

C).

The reels enable relay, charge circuit, glow and fan re-

lays along with their circuit wiring should be tested as

a TEC controller output with the Hand Held Diagnostic

Display (see Hand Held Diagnostic Display in the Trou-

bleshooting section of this chapter) or InfoCenter Dis-

play (see InfoCenter Display in this chapter) before

disconnecting and testing the relay.

Testing

1. Park machine on a level surface, lower cutting units,

stop engine, apply parking brake and remove key from

ignitionswitch. Remove rightside covernext tooperator

seat to allow access to relays.

2. Make sure ignition switch is in the OFF position. Lo-

cate the relay to be tested and disconnect wire harness

electrical connector from relay. Remove relay from

bracket for easier testing.

1. Relay (4 terminal) 2. Relay (5 terminal)

Figure 74

2

1

1. 48V battery pack 2. Reels enable relay

Figure 75

1

2

Figure 76

86 87

85 30

85 86

87

30