Groundsmaster 4500--D/4700--D Hydraulic SystemPage 4 -- 57

NOTE: GearpumpP1 supplieshydraulic flowtocutting

decks 5, 3 and 2 (also deck 7 onthe GM 4700--D). Gear

pump P2 supplies flow to cutting decks 1 and 4 (also

deck 6 on the GM 4700--D).

Procedure for Gear Pump P1 and P2 Flow Test

NOTE: Overa periodof time,thegears andwear plates

in the gear pump can wear.A worn pump will by pass oil

andmake thepump lessefficient.Eventually,enoughoil

loss will occur to cause the cutting deck motors to stall

under heavy cutting conditions. Continued operation

with a worn, inefficient pump can generate excessive

heat and cause damage to the seals and other compo-

nents in the hydraulic system.

1. Make sure hydraulic oil is at normal operating tem-

peraturebyoperatingthemachineforapproximatelyten

(10) minutes. Make sure the hydraulic tank is full.

2. Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is engaged.

3. Raise hood to allow access to pump assembly.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

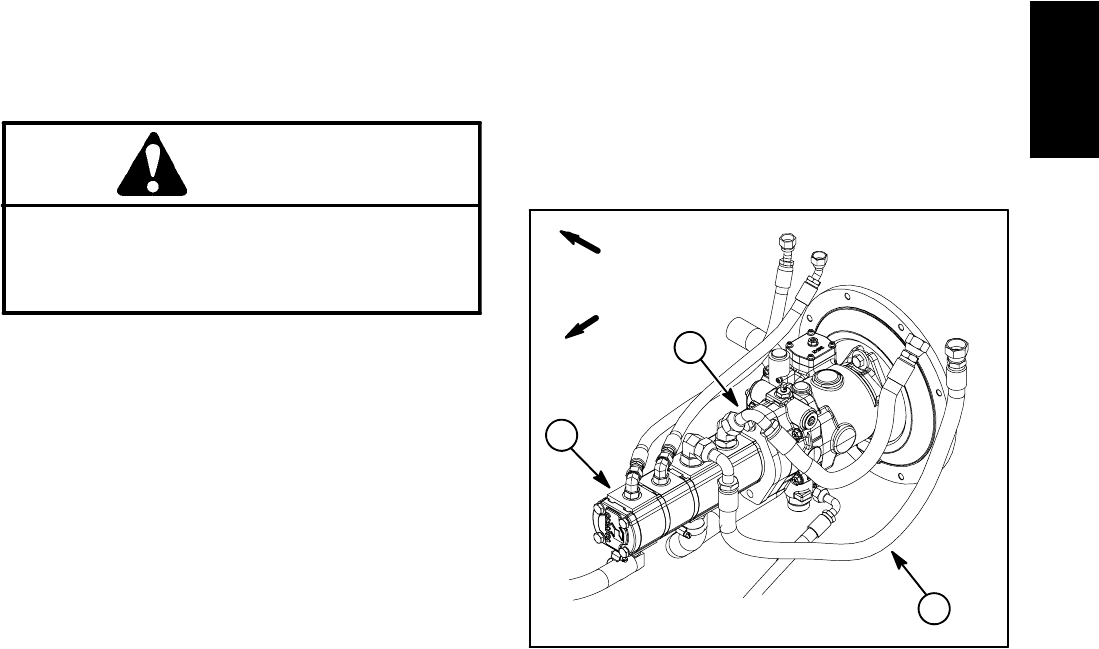

4. Locate gear pump section to be tested (P1 or P2).

Thoroughlyc lean junctionof appropriatehydraulic hose

and gear pump fitting. Disconnect hydraulic hose from

hydraulic fitting in gear pump (Fig. 48).

IMPORTANT: Make sure that the oil flow indicator

arrow on the tester is showing that the oil will flow

from the gear pump fitting, through the tester and

into the disconnected hose.

5. Install tester with pressure gauge and flow meter in

series with the disconnected hose and fitting in gear

pump section. Make sure the flow control valve on

the tester is fully open.

6. After installing tester, start engine and run at idle

speed. Check for hydraulic leakage and correct before

proceeding with test.

7. Start engine and move throttle to full speed (2870

RPM). Do not engage the cutting decks.

IMPORTANT: Do not fully restrict oil flow through

tester. In this test, the flow tester is positioned be-

fore thecircuit reliefvalve. Pumpdamage can occur

if the oil flow is fully restricted.

8. Watch tester pressure gauge carefully while slowly

closing the flow control valve on tester until 2000 PSI

(138 bar) is obtained. Verify witha phototac that the en-

gine speed is 2870 RPM.

9. For a pump in good condition, flow indication should

be approximately 11.5 GPM (43.5 LPM).

10.Fully open flow control valve on tester and then shut

engine off. Record test results.

11.If measured flow is less than 9.6 GPM (36.3 LPM)

or apressure of2000 PSI(138 bar) cannotbe obtained,

check for restrictionin the pumpintake line(including oil

filter and oil cooler). If line is not restricted, remove gear

pump and repair or replace as necessary.

12.After testing is complete, disconnect tester from hy-

draulic hose and fitting. Connect hose to the gear pump

fitting.

13.Repeat test for second pump section if required.

14.Lower and secure hood after testing is completed.

1. Gear pump

2. Pump section P1 hose

3. Pump section P2 hose

Figure 48

FRONT

RIGHT

1

3

2

Hydraulic

System