Groundsmaster 4500--D/4700--DPage 5 -- 2Electrical System

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Groundsmaster machine. Refer to the

Operator’s Manual for additional information when ser-

vicing the machine.

Toro Electronic Controllers (TEC)

Groundsmaster 4500--D machines use a single Toro

Electronic Controller (TEC--5002) to manage machine

electrical functions. Groundsmaster 4700--D machines

use two (2) Toro Electronic Controllers (TEC--5002 and

TEC--5001).

The controllers are microprocessor controlled that

sense the condition of various machine switches (in-

puts) and direct electrical power to control appropriate

machinefunctions (outputs)based onthes tate ofthein-

puts. The status of inputs to the controllers as well as

outputs from the controllers can be checked with the

Diagnostic Display (see Special Tools).

The controllers on the Groundsmaster 4700--D appear

identical butthey aredifferentin termsof theconnectors

and internal hardware. They are arranged in a master

(TEC--5002) / slave (TEC--5001) configuration and

therefore cannot be interchanged. Communication be-

tween the two controllers on the Groundsmaster

4700--D is provided with a CAN--bus system (see be-

low).

Because of the solid state circuitry built into the Toro

Electronic Controller (TEC), there is no method to test

it directly. The TEC may be damaged if an attempt is

made to test it with an electrical test device, such as a

digital multimeter.

IMPORTANT: Before performingany weldingon the

machine, disconnect the battery cables from the

battery, disconnect the wire harness connectors

from the Toro Electronic Controller(s) and discon-

nect the terminal connector from the alternator to

prevent damage to the machine electrical system.

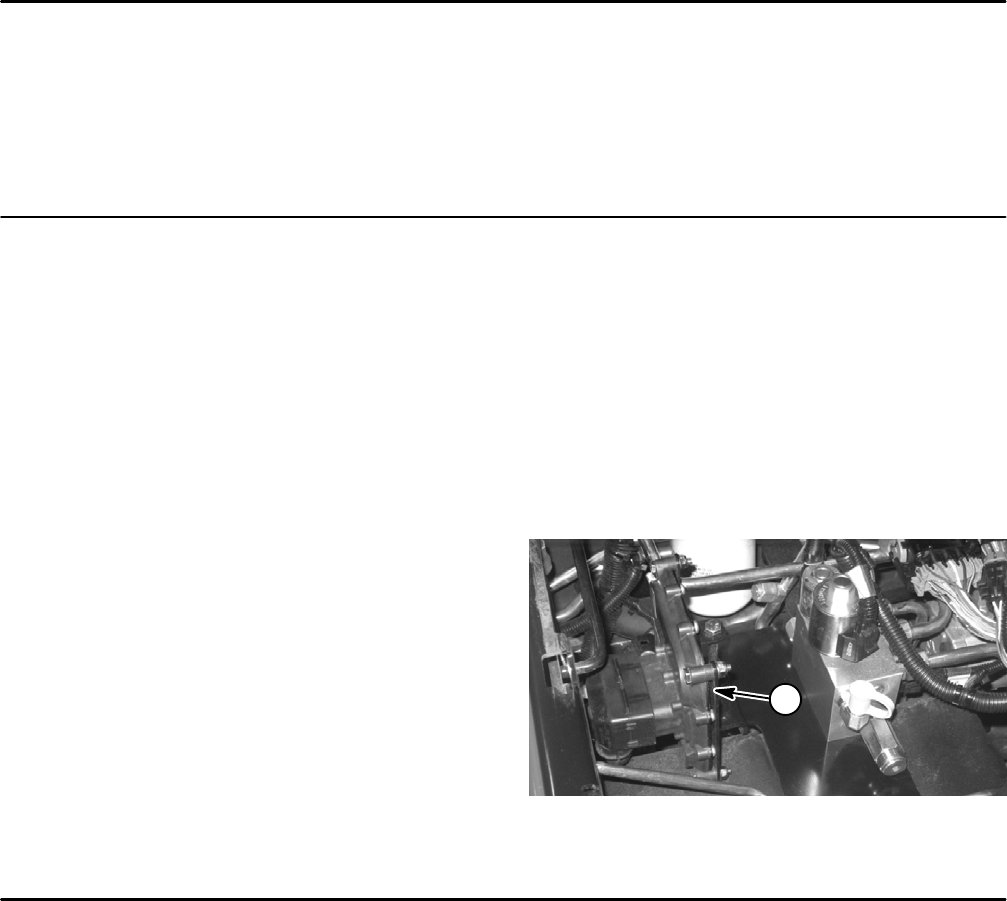

Figure 1

1

1. Toro Electronic Controller (GM 4500--D shown)

CAN--bus Communications (Groundsmaster 4700--D)

The two (2) TEC controllers (TEC--5002 and

TEC--5001) used on the Groundsmaster 4700--D com-

municate with each other on a CAN--bus system. Using

this system allows the traction unit to fully integrate all

the different electrical components of the tractor and

bring them together as one. The CAN--bus system re-

ducesthenumberofelectricalcomponentsandconnec-

tions used on the machine and allows the number of

wires in the wire harness to be significantly reduced.

CAN identifies the Controller Area Network that is used

betweenthe controllerson theGroundsmaster 4700--D.

Two (2)specially designed,twisted cablesform thebus.

These cables provide the data pathways between the

controllers(TEC--5002 andTEC--5001)usedon thema-

chine. The engineering term for these two cables are

CAN High and CAN Low. At the ends of the twisted pair

of bus cables are 120 ohm termination resistors.

Each of the components that is controlled by the CAN--

bus link only needs four (4) cables to operate and com-

municate to the system: CAN High, CAN Low, B+

(power) and ground.