Groundsmaster 4500--D/4700--D Page 5 -- 29 Electrical System

Engine Coolant and Hydraulic Oil Temperature Senders

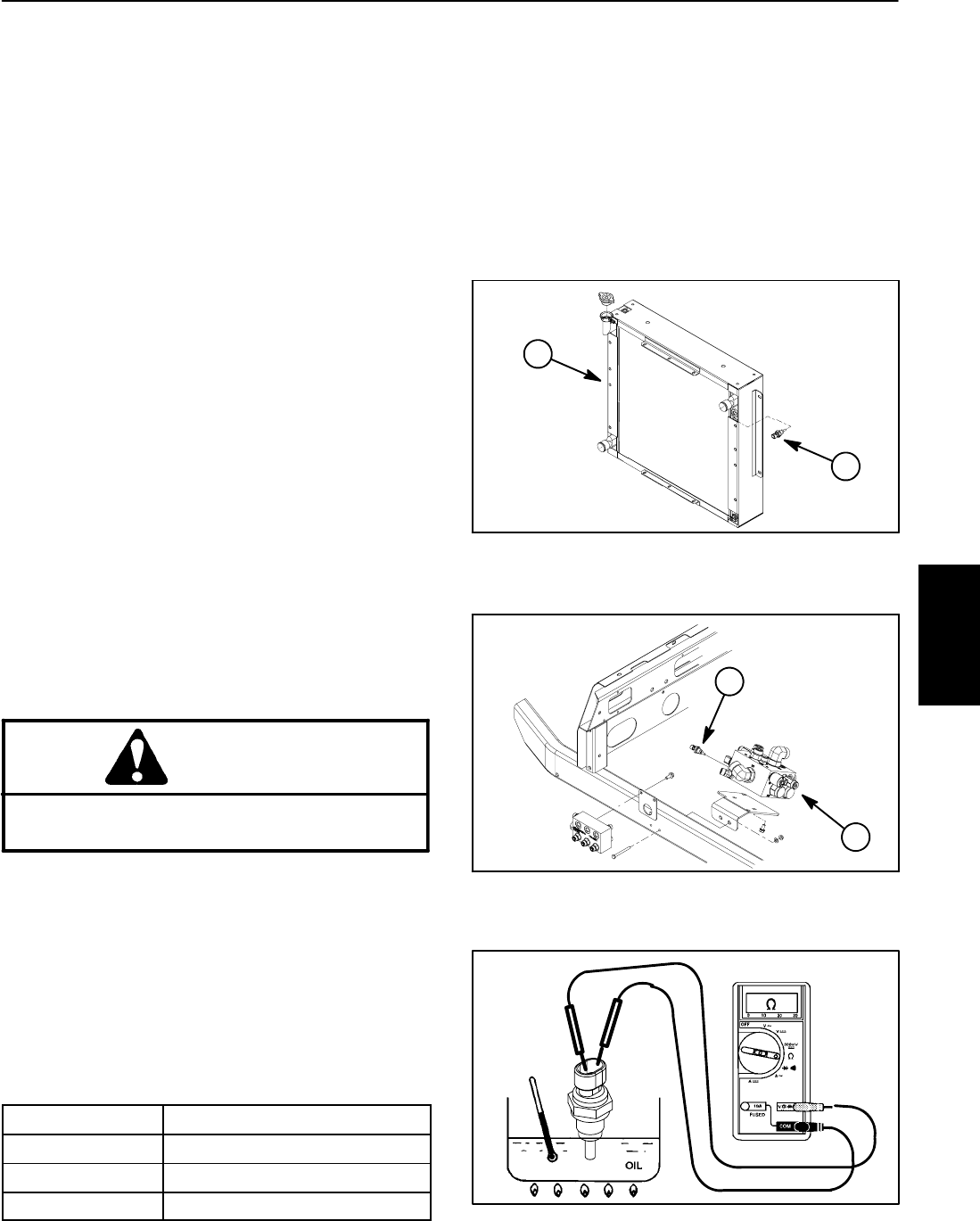

Two (2) identical temperature senders are used as in-

puts for the TEC--5002 controller to identify if either the

enginecoolant orhydraulic oiltemperature hasreached

an excessive level. The coolant temperature sender

threads into the radiator (Fig.39). The hydraulic oil tem-

perature sender is attached to the 4WD/2WD control

manifold at the front of the machine (Fig. 40).

Testing

1. Park machine on a level surface, lower cutting

decks, stop engine and engage parking brake.

2. Before disconnecting temperature sender for test-

ing, the sender and its circuit wiring should be tested as

a TECinput with theDiagnostic Display (seeDiagnostic

Display in the Troubleshooting section of this chapter).

If theD iagnostic Display verifies that thesender and cir-

cuit wiring are functioning correctly, no further sender

testingisnecessary.If,however,theDisplaydetermines

that the temperature sender and circuit wiring are not

functioning correctly, proceed with test.

3. Locate temperature sender that is to be tested. Dis-

connect wire harness connector from sender.

4. Thoroughly clean area around temperature sender

and remove sender.

5. Put sensing end of sender in a container of oil with

a thermometer and slowly heat the oil (Fig. 41).

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

NOTE: Prior to taking resistance readings with a digital

multimeter, short the meter test leads together. The me-

ter will display a small resistance value (usually 0.5

ohms or less). This resistance is due to the internal re-

sistance of the meter and test leads. Subtract this value

from from themeasured value of the testedcomponent.

6. Check resistance of the sender with a multimeter

(ohms setting) as the oil temperature increases. Re-

place sender if specifications are not met.

OIL TEMP

SENDER RESISTANCE

68

o

F(20

o

C) 11.6 to 13.5 ohms

140

o

F(60

o

C) 2.3 to 2.5 ohms

212

o

F (100

o

C) 0.6 to 0.7 ohms

7. After allowing the sender to cool, install sender:

A. Install new O--ring on sender and thread sender

into port. Torque from 9to11ft--lb(12.3to14.9

N--m).

B. Connect wire harness connector to sender.

8. Checkand fillsystem (coolantor hydraulic)toproper

level.

1. Radiator 2. Coolant temp sender

Figure 39

1

2

Figure 40

1. 4WD/2WD manifold 2. Oil temp sender

1

2

Figure 41

Electrical

System