Groundsmaster 4500--D/4700--D Hydraulic SystemPage 4 -- 55

Procedure for Cutting Deck Motor Case Drain Leak-

age Test

NOTE: Overa periodof time, adeck motorcan wearin-

ternally. A worn motor may bypass oil to its case drain

causing the motor to be less efficient. Eventually,

enough oil loss will cause the deck motor to stall under

heavy cutting conditions. Continued operation with a

worn, inefficient motor can generate excessive heat,

causedamage toseals andother componentsin thehy-

draulic system and affect quality of cut.

NOTE: One method to find a failing or malfunctioning

deck motor is to have another person observe the ma-

chine while mowing in dense turf. A bad motor will run

slower, produce fewer clippings and may cause adiffer-

ent appearance on the turf.

1. Make sure hydraulic oil is at normal operating tem-

peraturebyoperatingthemachineforapproximatelyten

(10) minutes. Make sure the hydraulic tank is full.

2. Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is engaged.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

NOTE: The deck motors are connected in series. To

isolate a faulty motor, all motors in the circuit may have

to be tested by starting with the first motor in the circuit

(see Hydraulic Schematic).

3. Disconnect pressure return hose from the motor to

be tested (Fig. 47). Install tester with pressure gauge

and flow meter in series with the motor and the discon-

nected return hose. Make sure the flow control valve on

tester is fully open.

4. Disconnect the motor case drainhose (small diame-

ter hose) where it connects to bulkhead fitting at the

frame rail (not at the motor). Put a steel cap on the bulk-

head fitting; leave the case drain hose open.

CAUTION

Cutting deck blades will rotate when lowered

with PTO switch in ON position. Keep away from

cutting decks during test to prevent personal in-

jury fromrotating blades. Donot stand infront of

the machine during test.

5. Sit on seat and start the engine. Move throttle to full

speed (2870 RPM). Move PTO switch to ON.

6. While watching tester pressure gauge, slowly close

flow control valve on tester until a pressure of 1200 PSI

(83 bar) is obtained.

NOTE: Use a graduated container, special tool

TOR4077, to measure case drain leakage.

7. Have a second person measure flow from the case

drain line for fifteen (15) seconds, then move the PTO

switch to OFF and stop the engine. Record test results.

TEST RESULTS: Case drain leakage less than 22.4

ounces(662 ml)ofhydraulic fluidin15 seconds(0.7

GPM / 2.7 LPM)

8. Ifcase drainflow ismorethan 22.4ounces (662ml),

the motor is worn or damaged and should be repaired

or replaced.

9. Disconnect tester from motor and hose. Reconnect

hose to the deck motor. Remove cap from bulkhead fit-

ting and reconnect case drain hose.

10.Repeat test for additional motors if required.

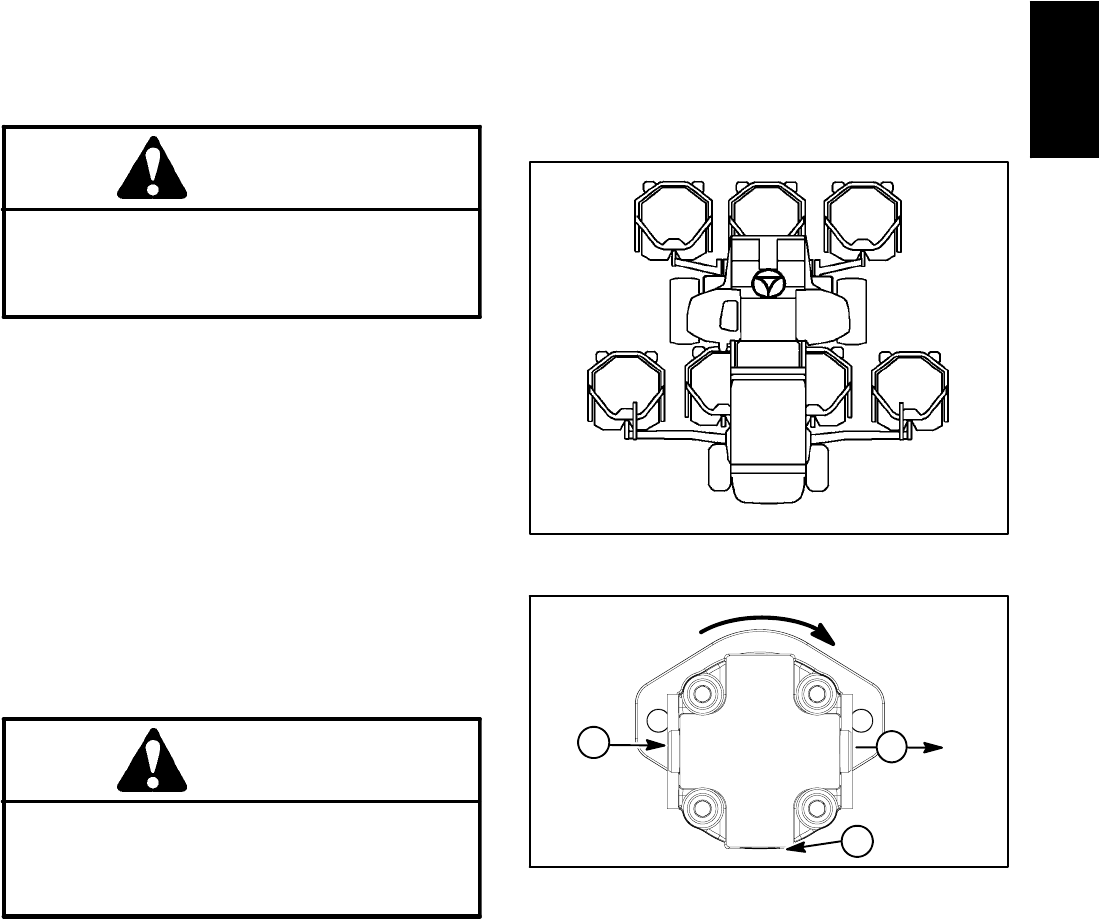

Figure 46

#4 #1 Deck #5

#7

(GM4700)

#6

(GM4700)

#3#2

CUTTING DECK LOCATIONS

1. Flow IN

2. Flow OUT

3. Case drain

Figure 47

ROTATION

2

1

DIRECTION

3

Hydraulic

System