Groundsmaster 4500--D/4700--D Hydraulic SystemPage 4 -- 31

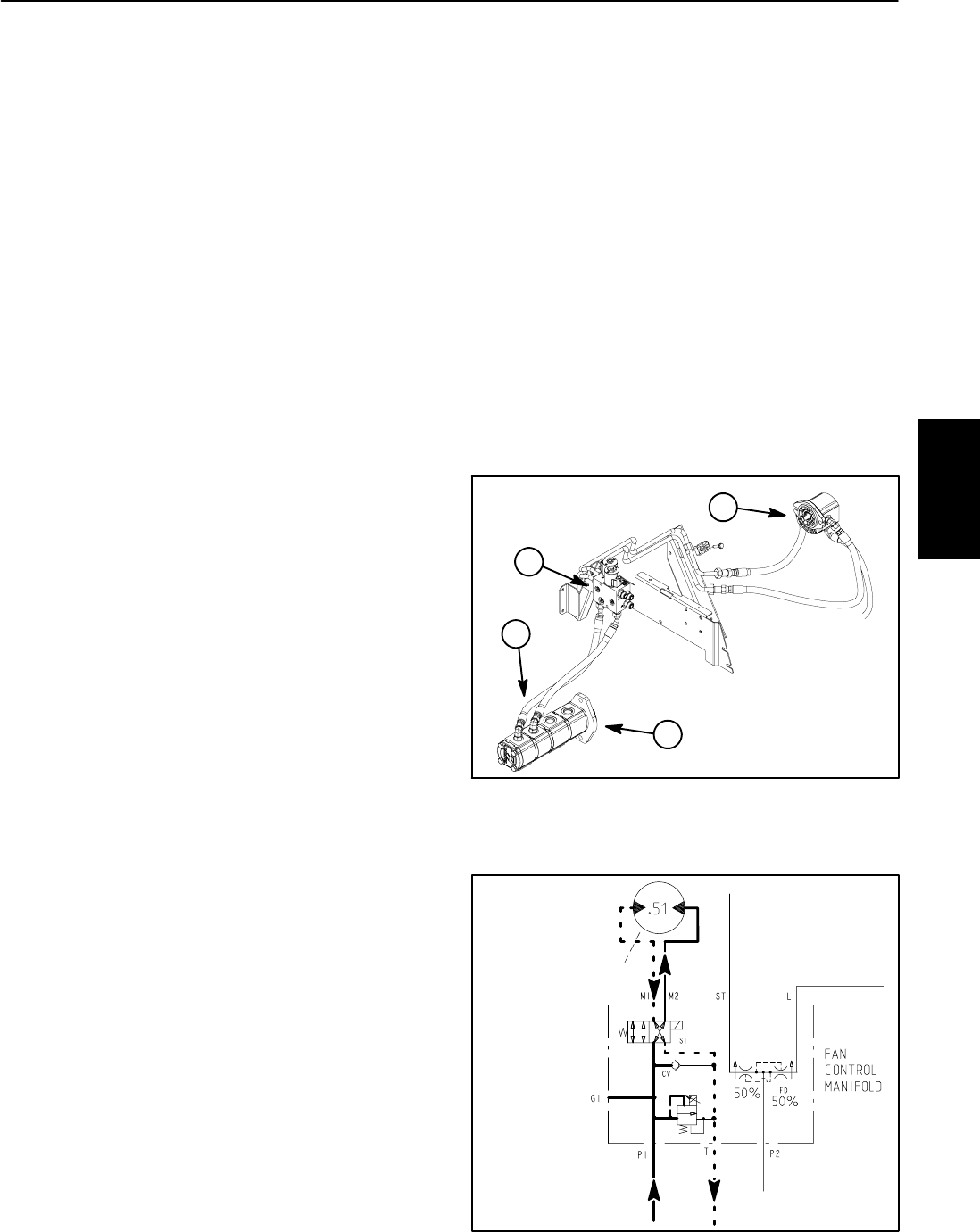

Engine Cooling Fan Circuit

A four section gear pump is coupled to the piston (trac-

tion) pump.The gearpump sectionP4 (farthestfromthe

piston pump) supplies hydraulic flow for the hydraulic

engine cooling fan motor (Fig. 24).

Thefancontrolmanifoldcontrols theoperationofthehy-

draulic motor that drives the engine cooling fan in addi-

tion to including the flow divider for the steering and lift

circuits. The electronically controlled proportional relief

valve (TS) in the manifold controls the oil flow to the fan

motor. The fan control manifold controls the speed and

directionof the fanmotorbased onelectrical outputfrom

the TEC--5002 controller.

Oil flow from the gear pump to the cooling fan motor is

controlled by the proportional relief valve (TS) in the fan

control manifold. This valve adjusts fan circuit flow

based on a PWM (Pulse Width Modulation) signal from

the TEC--5002 controller. The controller uses engine

coolant and hydraulic oil temperatures as inputs to de-

termine the properPWM signalfor the TSvalve. Thefan

circuit flow determines the speed of the cooling fan mo-

tor.

The fan motor runs at half speed until coolant reach-

es approximately 165

o

F(74

o

C). The fan motor in-

creases to full speed (approximately 2800 RPM) as

coolant reaches 180

o

F(82

o

C).

The fan motor automatically reverses if coolant

reaches203

o

F(95

o

C)orhydraulic oilreaches212

o

F

(100

o

C).

If the fan motor is stalled for any reason, the manifold

proportional relief valve (TS) has a s econdary function

as a circuit relief to limit fan motor pressure to 3000 PSI

(207 bar).

When the engine is shut off, the over--running inertia

load of the fan blades keeps driving the fan motor and

turnsit intoapump. Thecheck valve(CV) inthe fancon-

trol manifold will open to keep the motor circuit full of oil

so the fan motor will not cavitate.

NOTE: IfPWM currentis notavailable tothe fancontrol

manifold proportional relief valve (TS), the cooling fan

motor will run at full speed in the normal (forward) direc-

tion.

Forward Direction Fan Operation

Oilflow fromthe gearpump issentthrough thede--ener-

gized solenoid v alve S1 to rotate the cooling fan motor.

Return flow from the motor re--enters the manifold (port

M2),through thede--energized solenoidvalve S1,outof

themanifold (portT) andthenis routedthrough thedeck

control manifold, oil cooler and oil filter.

Reverse Direction Fan Operation (Fig. 25)

The TEC--5002 controller can reverse the cooling fan to

clean debris from the rear intake screen. If hydraulic oil

and/or engine coolant temperatures increase to an un-

suitable level or if the engine cooling fan switch is

pressed to manual reverse, a high PWM signal is sent

to the TS valve to slow the cooling fan and direct pump

oil flow away from the fan motor. The controller then en-

ergizes solenoid valve S1 in the fan control manifold to

reverse cooling fan motor oil flow so that the motor runs

in the reverse direction. A lower PWM signal is sent to

the TS valve allowing oil flow to return to the fan motor

but in the reverse direction causing the motor and cool-

ing fan to run in reverse for a short time.

NOTE: The fan reversal process is not designed to

clean the radiator of debris. Refer to Operator’s Manual

for radiator cleaning maintenance recommendations.

1. Gear pump

2. Fan control manifold

3. Fan circuit supply hose

4. Hydraulic fan motor

Figure 24

1

2

3

4

Figure 25

REVERSE

FROMGEAR

TOOILCOOLER

TORESERVOIR

TOLIFT/LOWER

CIRCUIT

TOSTEERING

CIRCUIT

PUMP(P3)

FROMGEAR

PUMP(P4)

DIRECTION

TS

Hydraulic

System