AC GENERATORS

SECTION 2.4

DIAGNOSTIC TESTS

RESULTS:

1. Repair, replace or reconnect wires as necessary.

2. Replace any damaged slip rings or brush holder.

3. Clean and polish slip rings as required.

TEST 13 – TEST ROTOR ASSEMBLY

(12-20 KW)

DISCUSSION:

A rotor having completely open windings will cause

loss of excitation current flow and, as a result,

generator AC output voltage will drop to “residual”

voltage. A “shorted” rotor winding can result in a

low voltage condition.

PROCEDURE:

I. Disconnect the brush wires or remove the brush holder,

to prevent interaction.

2. Set a VOM to measure resistance.

3. Connect the positive (+) VOM test lead to the posi-

tive (+) rotor slip ring (nearest the rotor bearing); and

the common (-) test lead to the negative (-) slip ring.

The meter should read rotor resistance. Compare to

“Specifications,” in the front of this manual.

4. Connect the positive (+) VOM test lead to the positive (+)

slip ring and the common (-) test lead to a clean frame

ground. The meter should indicate INFINITY.

RESULTS:

1. Replace rotor assembly if it is open or shorted.

2. If rotor tests good, perform “Insulation Resistance Test”

in Section 1.5.

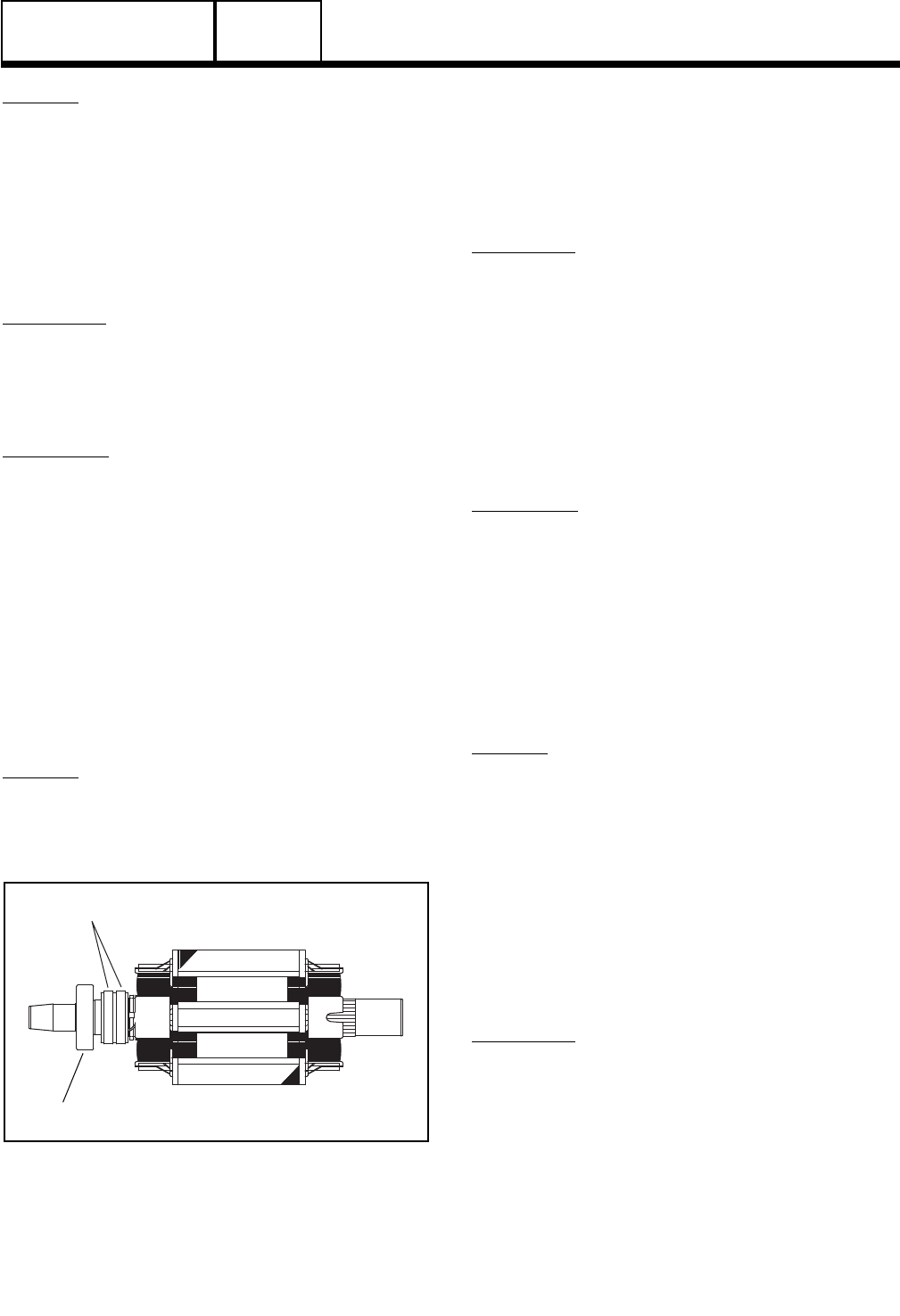

SLIP RINGS

BEARING

Figure 9. The Rotor Assembly

NOTE: Be sure to read Section 1.5, “Testing, Cleaning

and Drying”, carefully. If the rotor tests good, try per-

forming an insulation resistance test. Clean and dry the

rotor if it fails that test. Then, repeat the test. If the rotor

fails the second insulation resistance test, it should be

replaced.

TEST 14 – CHECK AC OUTPUT FREQUENCY

DISCUSSION:

The generator AC frequency is proportional to the

operating speed of the rotor. The 2-pole rotor will sup-

ply a 60 Hertz AC frequency at 3600 rpm. The unit’s

AC output voltage is proportional to the AC frequency.

For example, a unit rated 240 volts (line-to-line) will

supply that rated voltage (plus or minus 2 percent)

at a frequency of 60 Hertz. If, for any reason, the

frequency should drop to 30 Hertz, the line-to-line

voltage will drop to a matching voltage of 120 volts

AC. Thus, if the AC voltage output is high or low and

the AC frequency is correspondingly high or low, the

engine speed governor may require adjustment.

PROCEDURE:

1. Connect an accurate AC frequency meter across the

Wires 11 and 44 terminals of the generator main line

circuit breaker (see Figure 1, Section 2.4).

2. Start the engine, let it stabilize and warm up at no-load.

3. When engine has stabilized, read the frequency meter.

The no-load frequency for single cylinder units should

be about 62-63 Hertz. For V-Twin units, the no-load

frequency should be about 60 Hertz.

RESULTS:

1. If the AC frequency is high or low, go on to Test 15 for

single cylinder units, or Test 16 for V-Twin units.

2. If frequency is good, but voltage is high or low, go to

Test 17.

3. If frequency and voltage are both good, tests may be

discontinued.

TEST 15 – CHECK AND ADJUST ENGINE

GOVERNOR (SINGLE CYLINDER UNITS)

DISCUSSION:

The generator AC frequency output is directly pro-

portional to the speed of the rotor. A two-pole rotor

(having a single north and a single south magnetic

pole) will produce an AC frequency of 60 hertz at

3600 RPM.

The generator is equipped with a “voltage over fre-

quency” type AC voltage regulator. The units AC

output voltage is generally proportional to AC fre-

quency. A low or high governor speed will result in a

correspondingly low or high AC frequency and voltage

output. The governed speed must be adjusted before

any attempt to adjust the voltage regulator is made.

PART 2

Page 49