AC GENERATORS

SECTION 2.1

DESCRIPTION & COMPONENTS

PART 2

Page 33

SLIP RINGS

BEARING

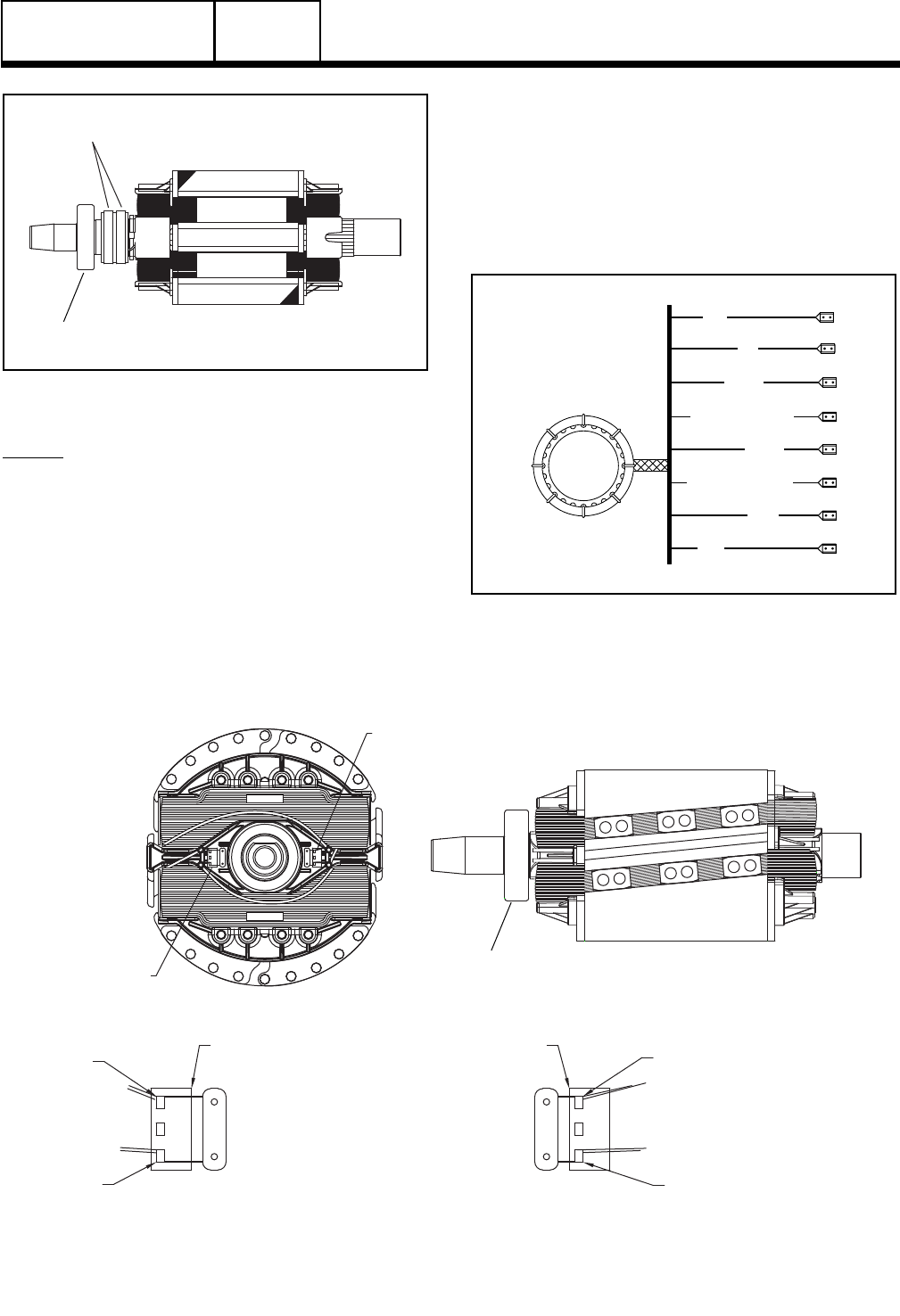

Figure 2. The 2-Pole Rotor Assembly 12-20 kW

8/10KW:

Like the 12-20 kW rotor, the 8/10 kW 2-pole rotor must

be operated at 3600 rpm to supply a 60 Hertz AC fre-

quency. However, the 8/10kW rotor uses no slip rings.

As the rotor rotates in the generator voltage is induced

from the Excitation winding using a capacitor that is in

turn excited by the rotor. A continuous loop of charging

and discharging of the capacitor is maintained that

acts as a voltage regulation system. The rotor bearing

is pressed onto the end of the rotor shaft. The tapered

rotor shaft is mounted to a tapered crankshaft and is

held in place with a single through bolt.

STATOR ASSEMBLY

The stator can houses and retains (a) dual AC power

windings, and (b) excitation winding. A total of six (6)

or eight (8) stator leads are brought out of the stator

can as shown in Figure 4.

The stator can is sandwiched between an engine

adapter and a rear bearing carrier. It is retained in that

position by four stator studs.

2

6

11P

44

33

22S (12-20 kW)

22P

11S

(12-20 kW)

Figure 4. Stator Assembly Leads

CATHODE

ANODE

DIODE B

DIODE B

CATHODE

DIODE A

COIL 2

ANODE

COIL 1

DIODE A

BEARING

Figure 3. The 2-Pole Rotor Assembly 8/10kW