GENERAL INFORMATION

SECTION 1.5

TESTING, CLEANING AND DRYING

PART 1

HI-POT TESTER:

A “Hi-Pot” tester is shown in Figure 7. The model

shown is only one of many that are commercially

available. The tester shown is equipped with a voltage

selector switch that permits the power supply voltage

to be selected. It also mounts a breakdown lamp that

will illuminate to indicate an insulation breakdown dur-

ing the test.

STATOR INSULATION RESISTANCE TEST

(12-20 KW)

GENERAL:

Units with air-cooled engine are equipped with (a)

dual stator AC power windings, and (b) excitation or

DPE winding. Insulation tests of the stator consist of

(a) testing all windings to ground, (b) testing between

isolated windings, and (c) testing between parallel

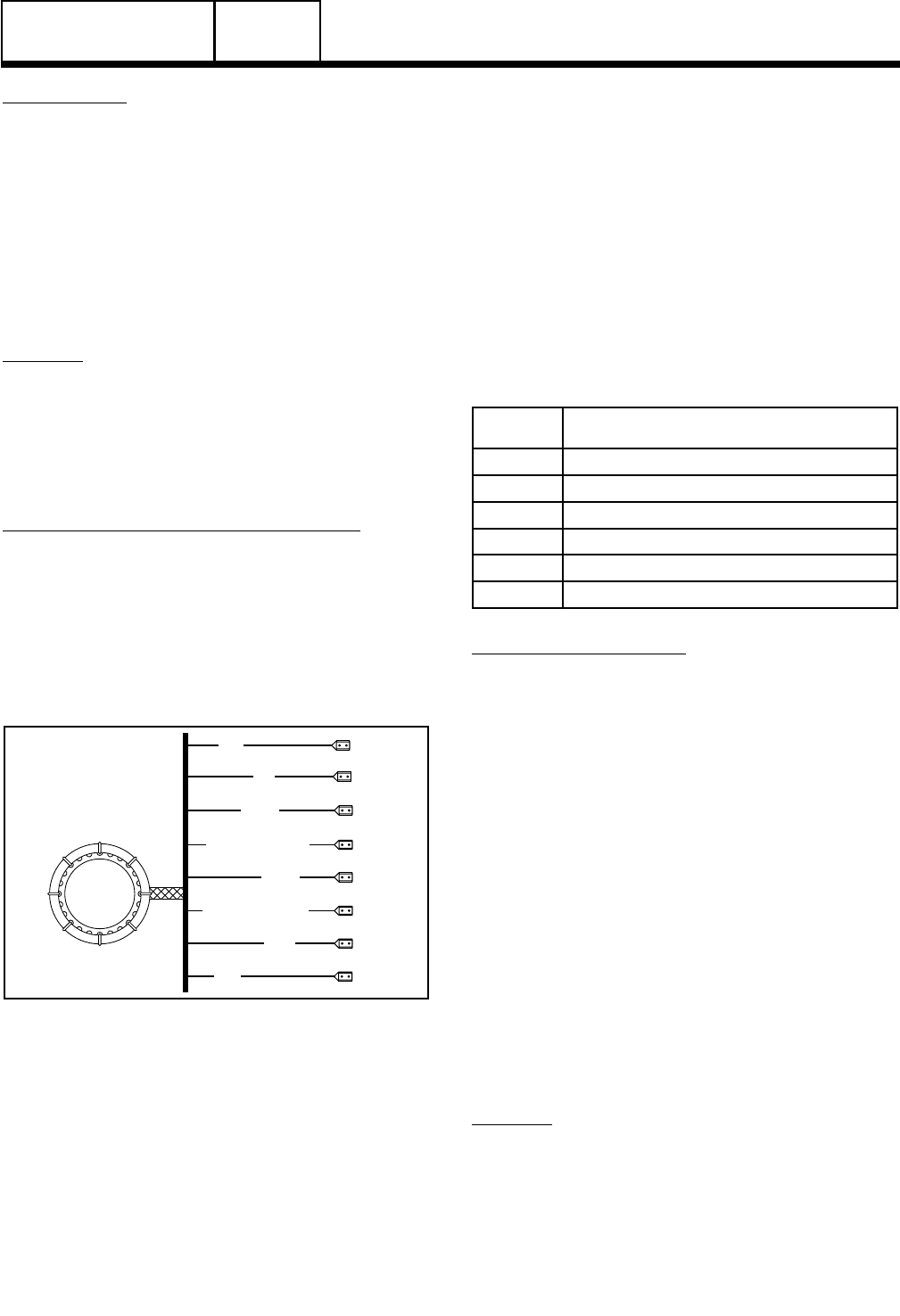

windings. Figure 8 is a pictorial representation of the

various stator leads on units with air-cooled engines.

TESTING ALL STATOR WINDINGS TO GROUND:

1. Disconnect stator output leads 11 and 44 from the gen-

erator main line circuit breaker.

2. Remove stator output leads 22 and 33 from the neutral

connection and separate the two leads.

3. Disconnect Wires 11 and 22 from Voltage Regulator.

Ensure these wires are not touching any other compo-

nents on the generator.

2

6

11P

44

33

22S (12-20 kW)

22P

11S

(12-20 kW)

Figure 8. Stator Winding Leads

4. Connect the terminal ends of Wires 11, 22, 33 and 44

together. Make sure the wire ends are not touching any

part of the generator frame or any terminal.

5. Connect the red test probe of the Hi-Pot tester to the

joined terminal ends of stator leads 11, 22, 33 and 44.

Connect the black tester lead to a clean frame ground

on the stator can. With tester leads connected in this

manner, proceed as follows:

a. Turn the Hi-Pot tester switch OFF.

b. Plug the tester cord into a 120 volt AC wall

socket and set its voltage selector switch to

“1500 volts”.

c. Turn the tester switch ON and observe the

breakdown lamp on tester. DO NOT APPLY

VOLTAGE LONGER THAN 1 SECOND. After

one (1) second, turn the tester switch OFF.

If the breakdown lamp comes on during the one-sec-

ond test, the stator should be cleaned and dried. After

cleaning and drying, repeat the insulation test. If, after

cleaning and drying, the stator fails the second test,

the stator assembly should be replaced.

6. Proceed to the Voltage Regulator. Each winding will be

individually tested for a short to ground. Refer to Steps

5a-5c and perform the same test on the following wires:

Wire

Number

Winding

22S Sense Lead Power

11S Sense Lead Power

6 Excitation

2 Excitation

0 Ground

4 Positive to Brush Ground

TEST BETWEEN WINDINGS:

1. Disconnect Stator Output Leads 11 and 44 from the

generator main line circuit breaker.

2. Remove Stator Output Leads 22 and 33 from the neutral

connection and separate the two leads.

3. Disconnect Wires 11, 22, 2, and 6 from Voltage

Regulator. Ensure these wires are not touching any

other components on the generator.

4. Connect the red tester probe to Wire 2. Connect the

black tester probe to Stator Lead 11. Refer to Steps 5a

through 5c of “TESTING ALL STATOR WINDINGS TO

GROUND” on previous page.

5. Repeat Step 4 between Wire 2 and Stator Lead 33.

6. Repeat Step 4 between Stator Lead 11 and Stator Lead 33.

STATOR INSULATION RESISTANCE TEST

(8-10 KW)

GENERAL:

Units with air-cooled engine are equipped with (a)

dual stator AC power windings, and (b) excitation or

DPE winding. Insulation tests of the stator consist of

(a) testing all windings to ground, (b) testing between

isolated windings, and (c) testing between parallel

windings. Figure 8 is a pictorial representation of the

various stator leads on units with air-cooled engines.

Page 23